Valve less thin film driving micro pump

A film-driven, micro-pump technology, applied in pumps, machines/engines, pumps with flexible working elements, etc., can solve problems such as unstable flow, and achieve the effects of fast response, easy integration, and simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

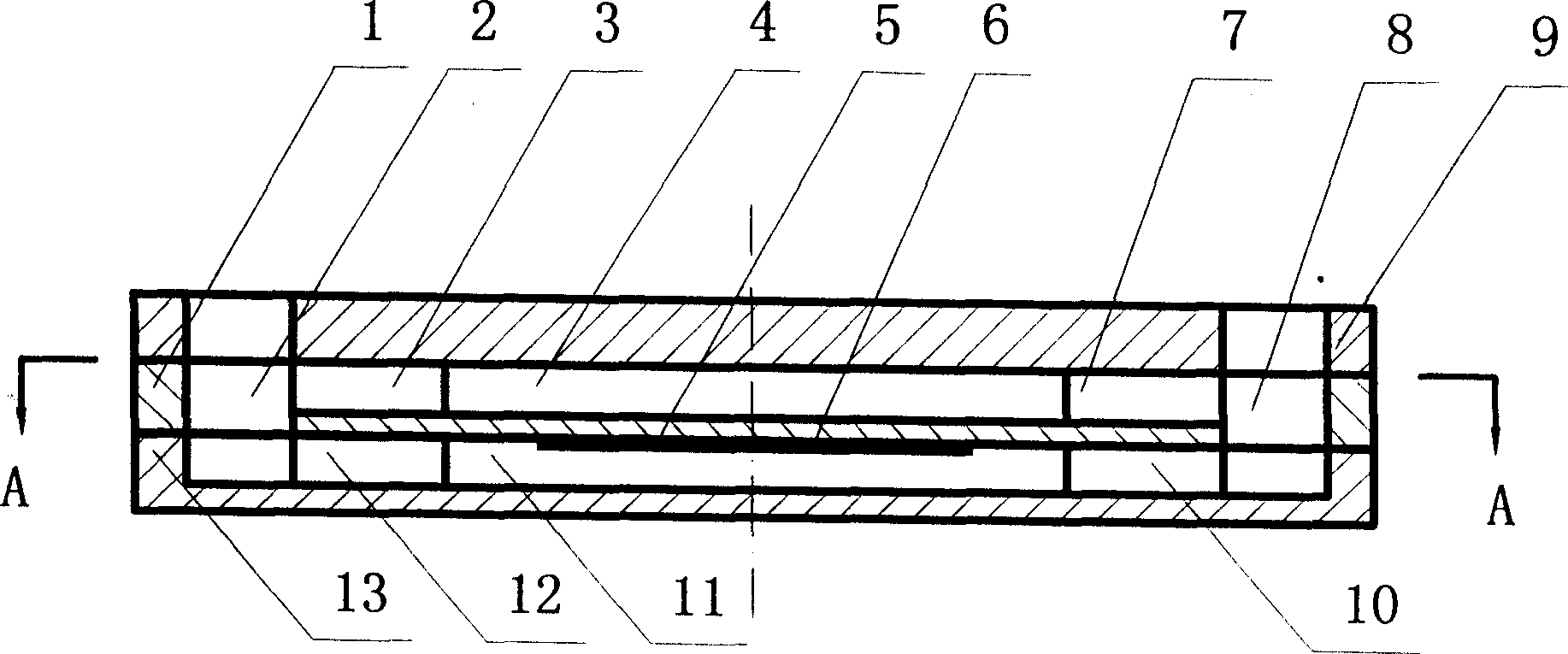

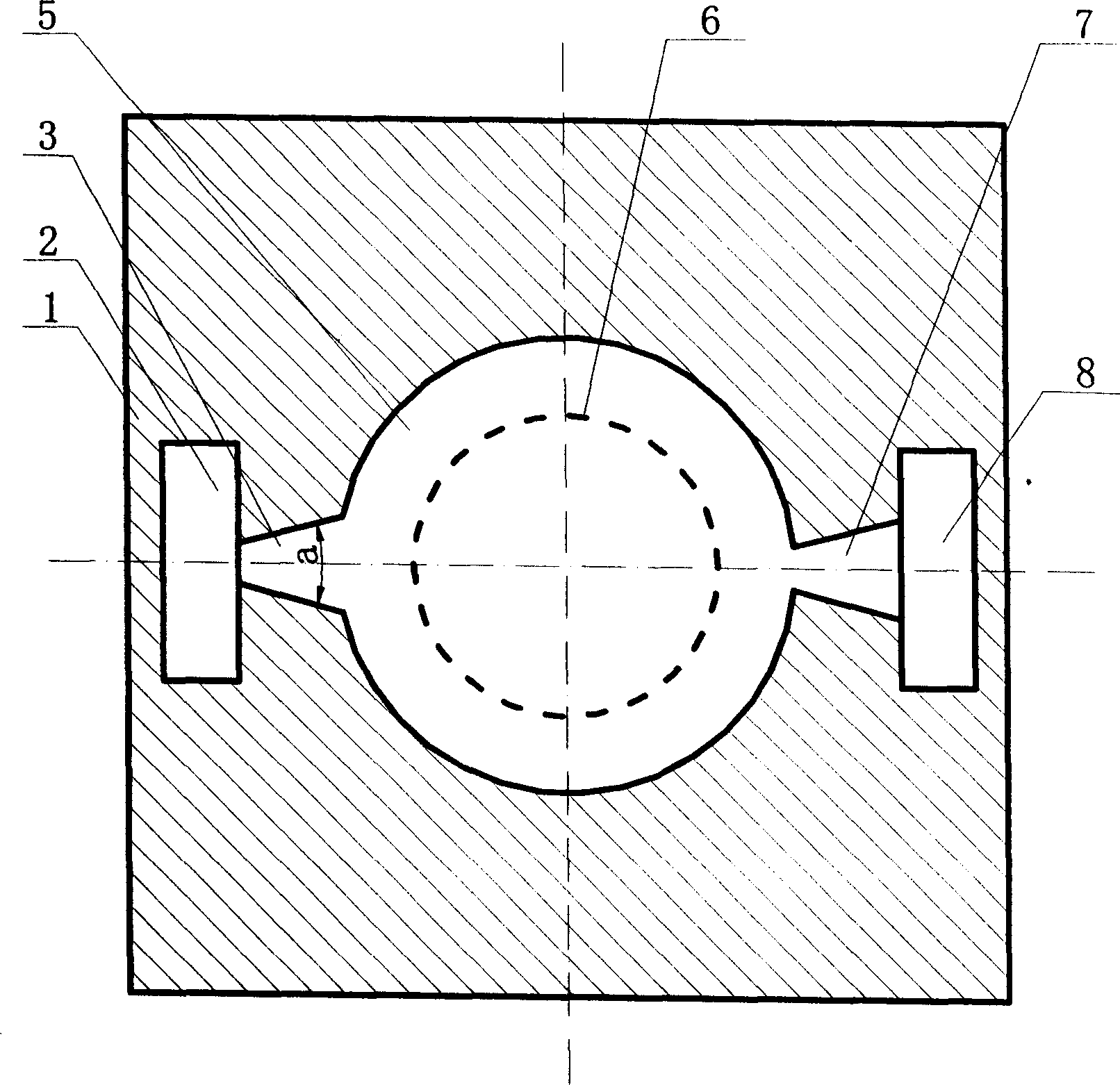

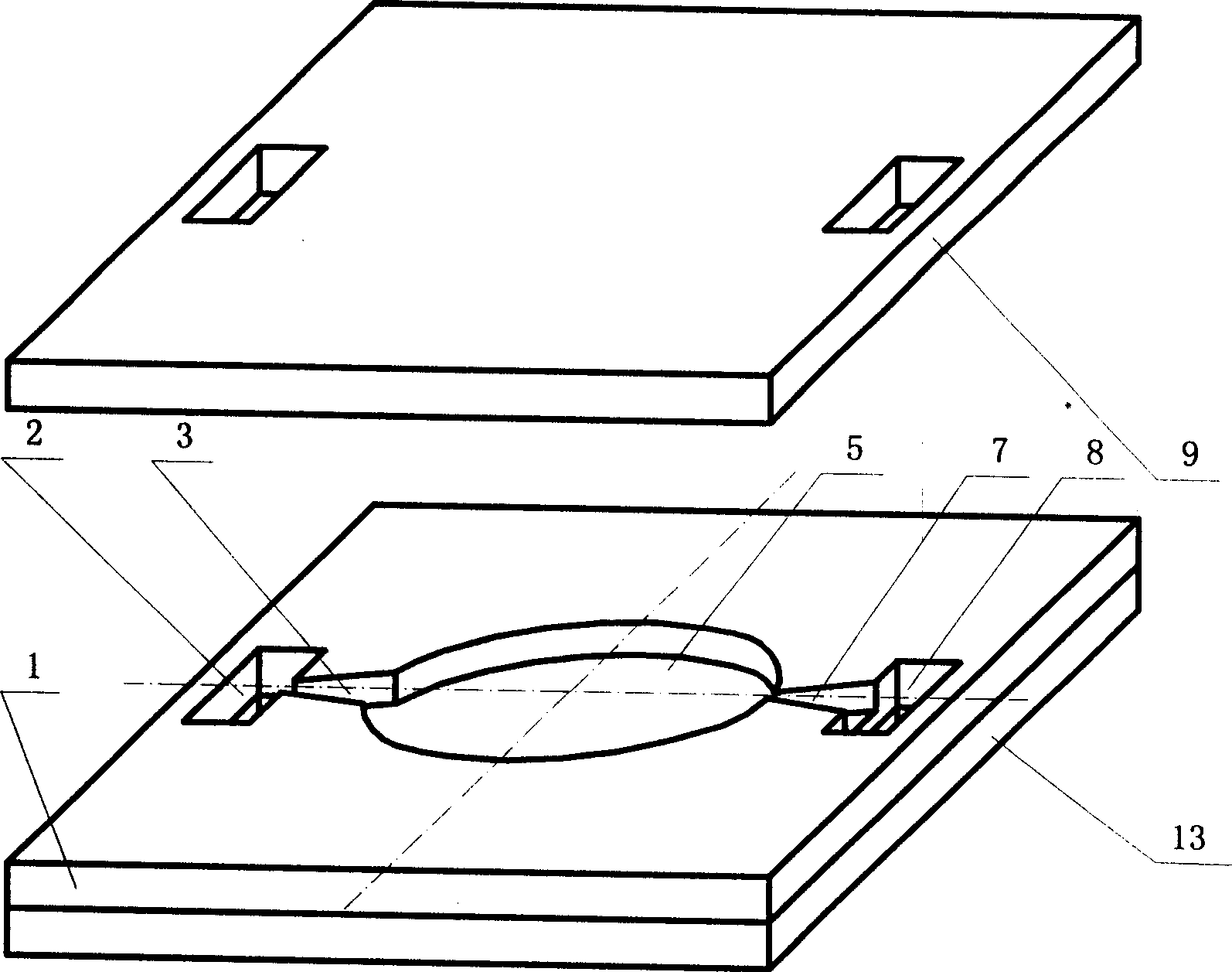

[0014] Such as figure 1 , figure 2 , image 3 As shown, an upper pump chamber 4, a tapered diffuser tube 3, a tapered shrink tube 7, a left water hole 2 and a right water hole 8 are opened on the upper pump body 1, and on the surface of the basement membrane 5 of the upper pump body 1 A layer of functional film 6 is provided to form a driving film, which may be a piezoelectric film or a magnetoelectric film. The upper pump chamber 4 is connected with the water hole 2 through the diffuser tube 3 and connected with the water hole 8 through the shrink tube 7 . There is a lower pump body 13 below the upper pump body 1, and a corresponding lower pump chamber 11, a tapered diffuser tube 12, a tapered shrink tube 10, and corresponding water holes 2 and water holes 8 are opened on the lower pump body 13. The pump chamber 11 is connected with the water hole 2 through the diffuser tube 12 and connected with the water hole 8 through the shrink tube 10 . The upper and lower pump cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com