Multistage fumes decontamination device for desulfurization and dust precipitation

A technology for desulfurization, dust removal, and purification devices, which is applied in chemical instruments and methods, dispersed particle separation, and the use of liquid separators, etc., can solve the problems of high operating costs and maintenance costs, poor desulfurization effect, etc., and achieve uniform gas-liquid reaction area. , Simple structure, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

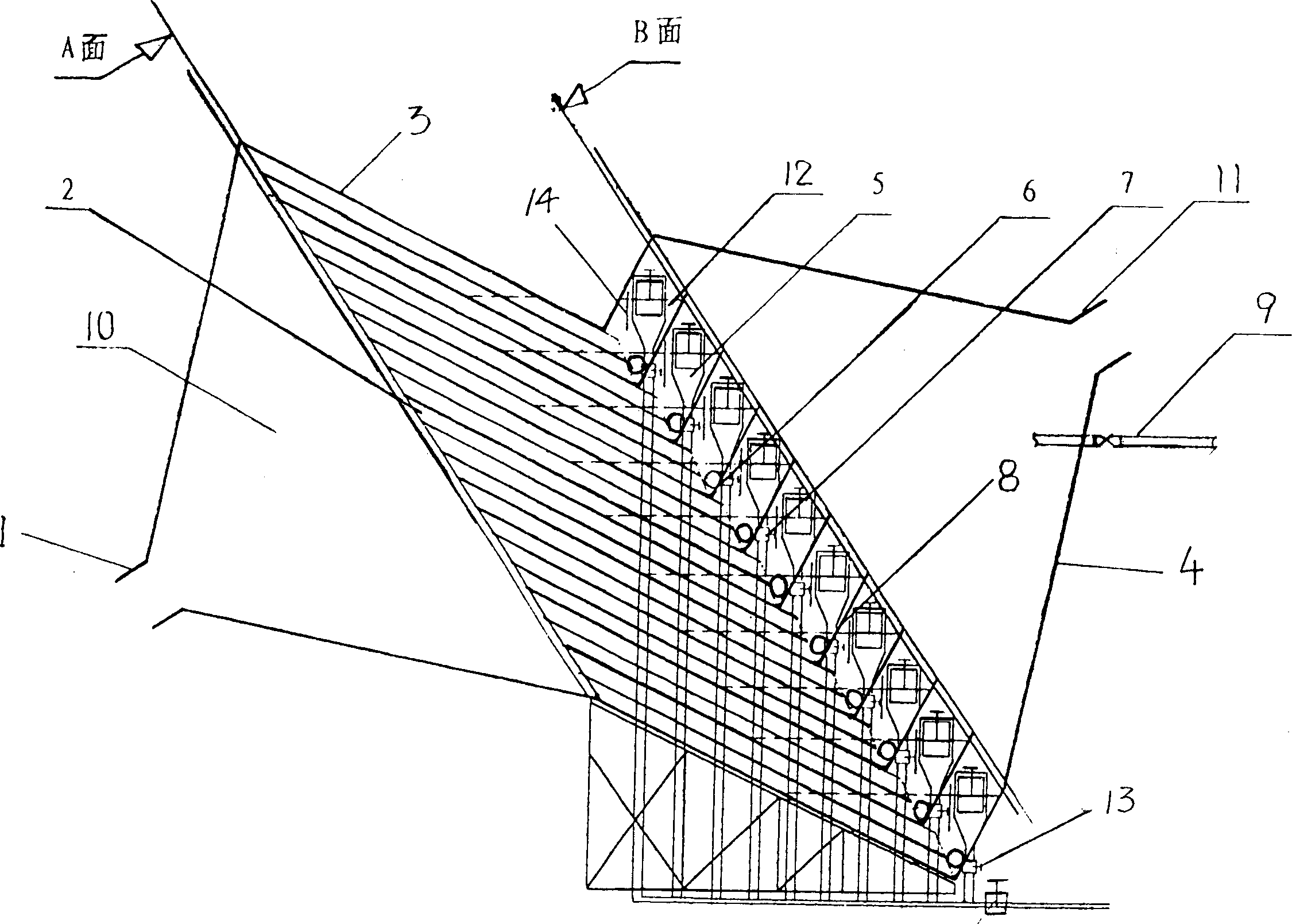

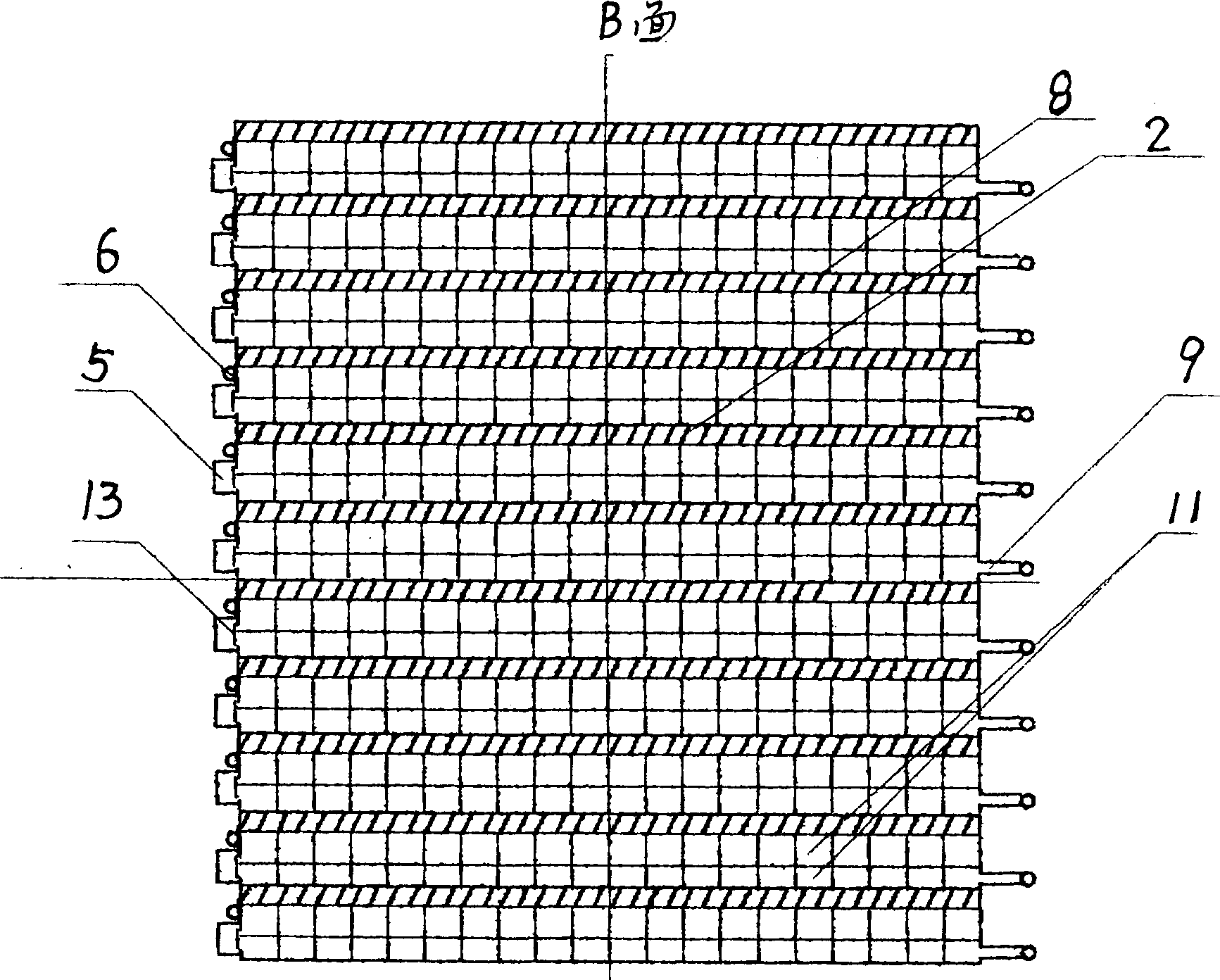

[0015] exist figure 1 The multi-stage flue gas desulfurization and dedusting purification device includes an inlet pipe (1), a diffuser pipe (10), a shrinkage pipe (4), a reaction main pipe (3), an air outlet pipe (11), a liquid inlet pipe (9), an outlet pipe Liquid pipe (7), the front end of the diffuser pipe (10) is connected to the inlet pipe (1), the rear end is connected to the reaction main pipe (3), and a shrinkage pipe ( 4), the central section of the reaction main pipe (3) forms an angle of 150° with the horizontal plane, and 20 layers of reaction branch pipes (2) are evenly arranged in the reaction main pipe (3), and each layer includes 22 reaction branch pipes (2) , the water baffle (8) is positioned at the end of that layer of reaction branch (2) at the lower end of every two layers of reaction branch (2), and forms a liquid storage tank (12) with the bottom surface of this layer of reaction branch (2), A ∨-shaped liquid storage tank (12) with an angle of 105° is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com