Flame stand for stove and glass plate stove

A glass panel and flame technology, applied in the direction of stove/stove top, application, household stove, etc., can solve the problems of uneven secondary air, unsightly, disturbing secondary air, etc., to prevent adhesion and improve combustibility , clean up simple effect

Inactive Publication Date: 2003-10-15

RINNAI CORP

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because this part is close to the burner, the radiated heat is at a relatively high temperature, and it is the place where the spilled soup or cooking food is easily scorched and accumulated because such things exist in the secondary air passage. At the outlet of the burner, it will definitely disturb the secondary air before entering the burner, so that the secondary air supplied to the burner will be uneven, which will definitely have a bad effect on the combustibility

[0005] In addition, although it is also considered to use a traditional flame support on the glass panel stove, the presence of the partition plate will give a bulky feeling to the flame support, which will detract from the beautiful appearance of the glass panel stove. , extremely unsightly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0024] Burner input

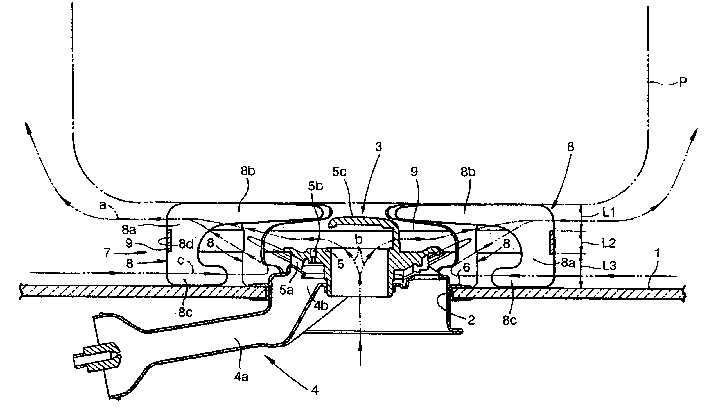

[0025]As can be seen from the above table, according to the embodiment of the present invention, the combustibility of the burner 3 is improved, and the thermal efficiency is also improved while reducing the amount of CO generated.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

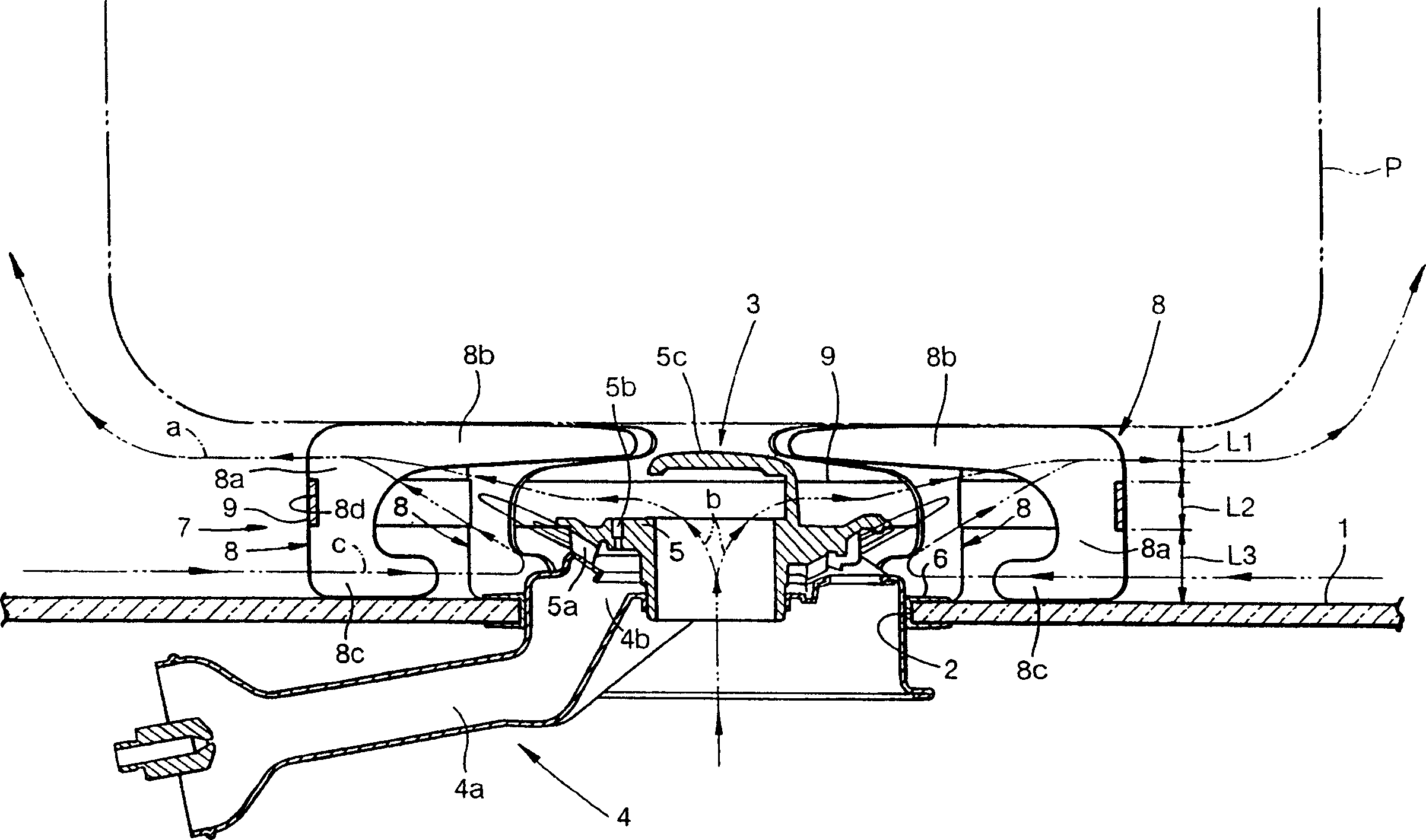

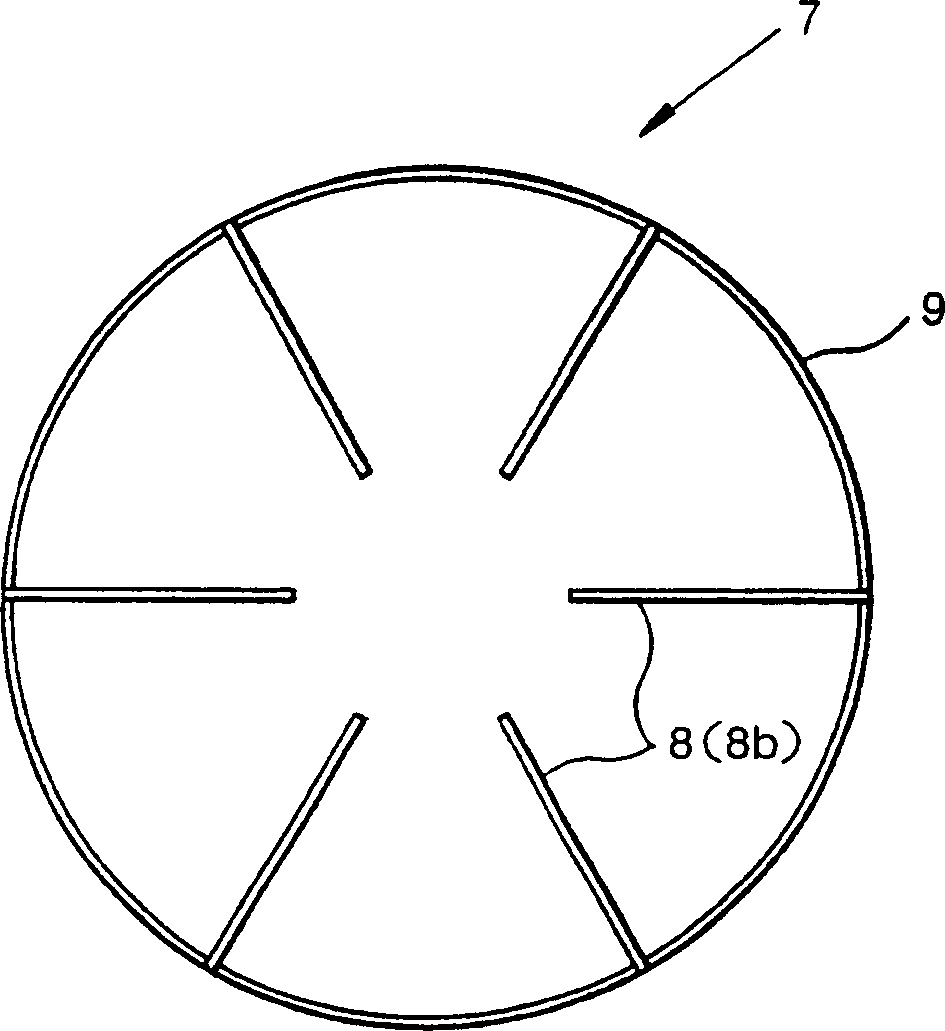

This invention provides a trivet and a glass top stove. An annular frame (9) is arranged on the trivet (7). The annular frame (9) is located below the upper edge of the trivet claws (8) and above the lower ends of the foot portions (8a) of the trivet claws (8), and is formed by a band-like plate extending up and down along the width direction. A plurality of trivet claws (8) are fixed to the annular frame (9) at the respective foot portions (8a) of the trivet claws. The combustion exhaust gas of the burner (3) flows through an upper space of the annular frame (9) and exits to the exterior. The secondary air flows smoothly from a lower space of the annular frame (9) along the glass top panel (1) to the burner part. The trivet of the invention separates the flow of the combustion exhaust ga s and the flow of the secondary air to enhance the combustibility of a burner and that is suitable for a glass top stove.

Description

technical field [0001] The present invention relates to a flame holder for a stove, which is provided with a plurality of flame holder claws spaced apart from each other in the circumferential direction, and a glass panel stove using the flame holder. Background technique [0002] As we all know, according to Japanese Patent Laid-Open No. 58-102032, the flame support for stoves in the past is provided with a wide annular partition in the diameter direction, and makes it under the upper edge of the flame support claw and the legs of the flame support. Above the lower end, a plurality of flame support claws are inserted and fixed on the dividing plate at the legs. The flame support can divide the combustion exhaust flow discharged from the burner and the secondary air flow supplied to the burner into upper and lower parts through the partition plate, which is beneficial to improve the combustibility of the burner. [0003] In addition, the above-mentioned flame support is use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F24C15/10F24C3/02

CPCA47B13/12F24C3/008F24C15/107

Inventor 重野秀树

Owner RINNAI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com