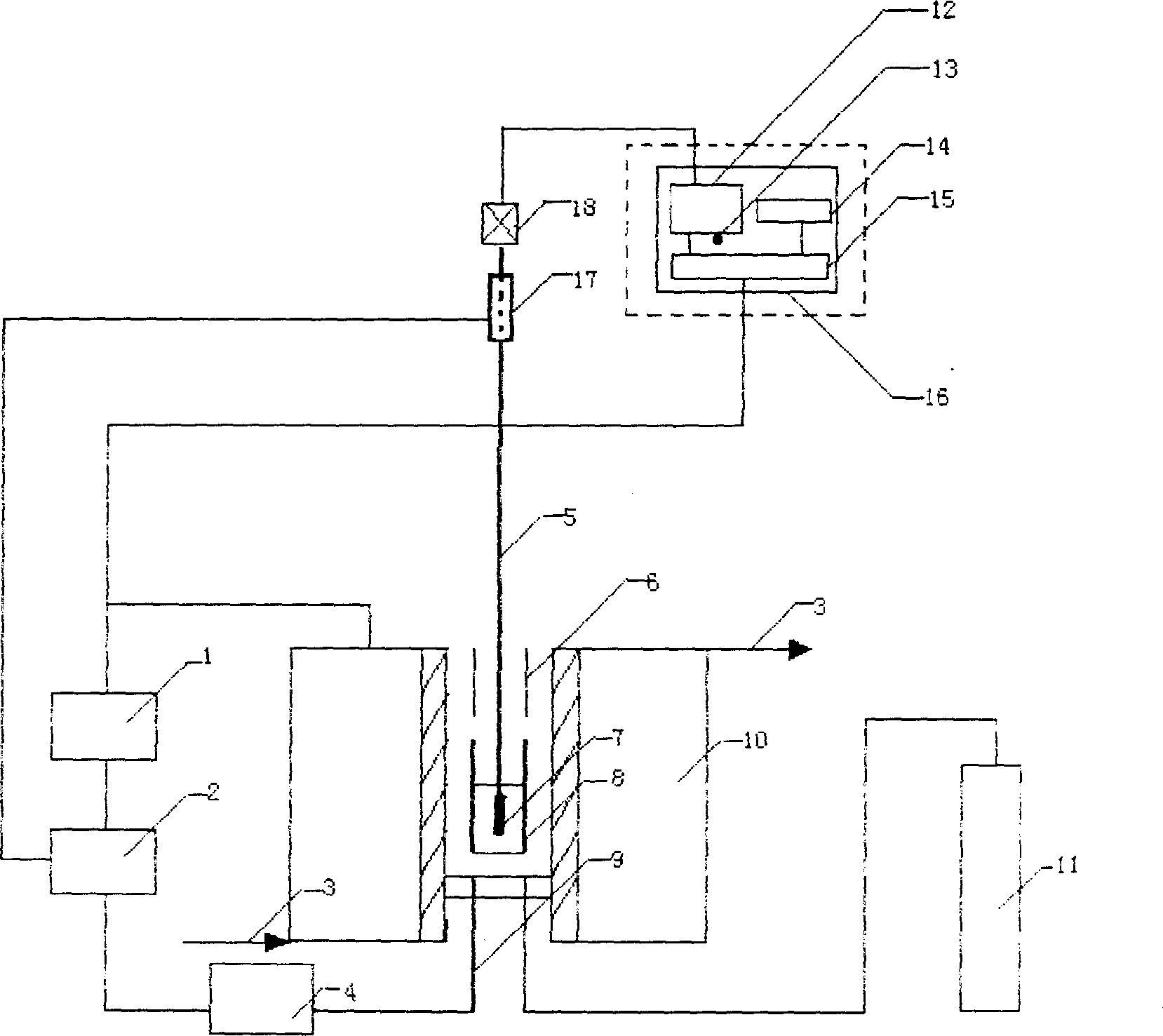

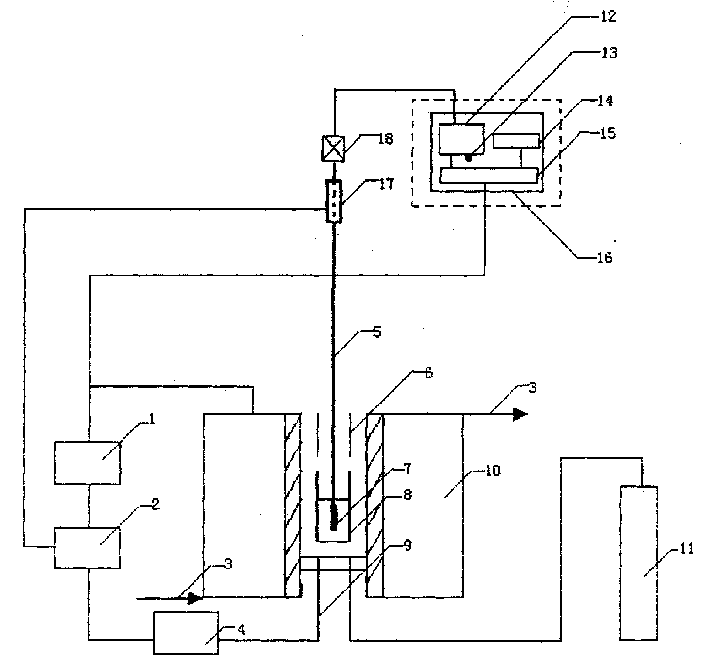

Instrument for determining rheological properties of Non-Newtonian viscosity fluid

A viscous fluid and rheological characteristics technology, applied in the field of fluid mechanics, can solve the problems of not being able to obtain the shear rate and measuring the change of viscosity with the rotating speed, etc., and achieve the effect of high utilization efficiency and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the experiment, standard oils GBW13608 and GBW13609 issued by China Institute of Metrology were used, and their dynamic viscosity values were 0.5153Pas and 0.9193Pas respectively. According to the statistics of multiple sets of experimental data, the average variance of the viscosity data is σ=0.0391, indicating that the modified experimental device has high reliability.

[0014] According to the error analysis method of uncertainty, the measurement system error can be divided into two parts: one is random uncertainty, such as the standard deviation σ value obtained when measuring the viscosity of standard oil; the other is system uncertainty, including Viscometer or standard oil error, temperature control equipment error, torque sensor error. Table 1 shows the system error analysis of the improved melt physical property tester in measuring rheological properties. According to the formula of error transmission, the maximum relative error of the system is the sum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com