Parallel simulator with redundancy inputs

A redundant input and simulator technology, applied in the field of mechanics, can solve the problems of complex equipment structure, high manufacturing and maintenance costs, environmental pollution, etc., and achieve the effect of solving complex equipment structure, easy equipment manufacturing and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

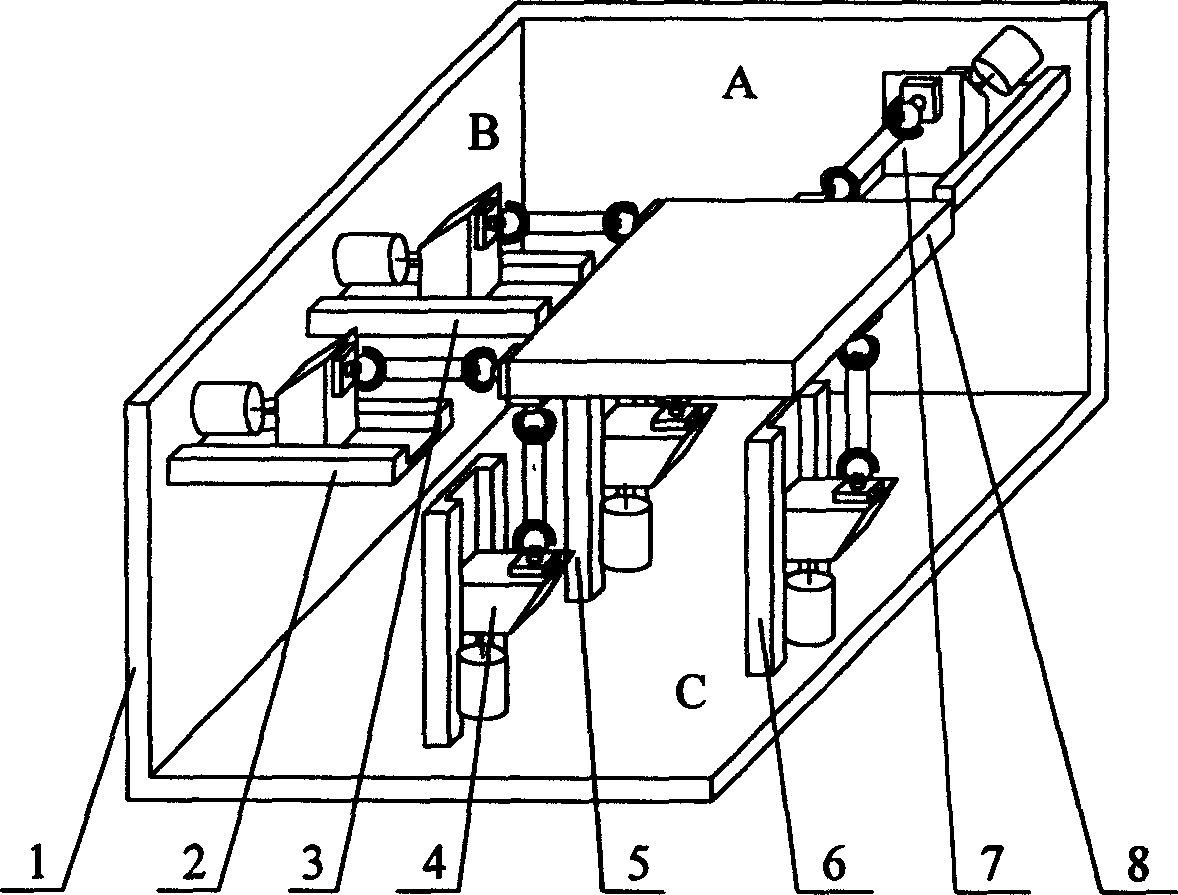

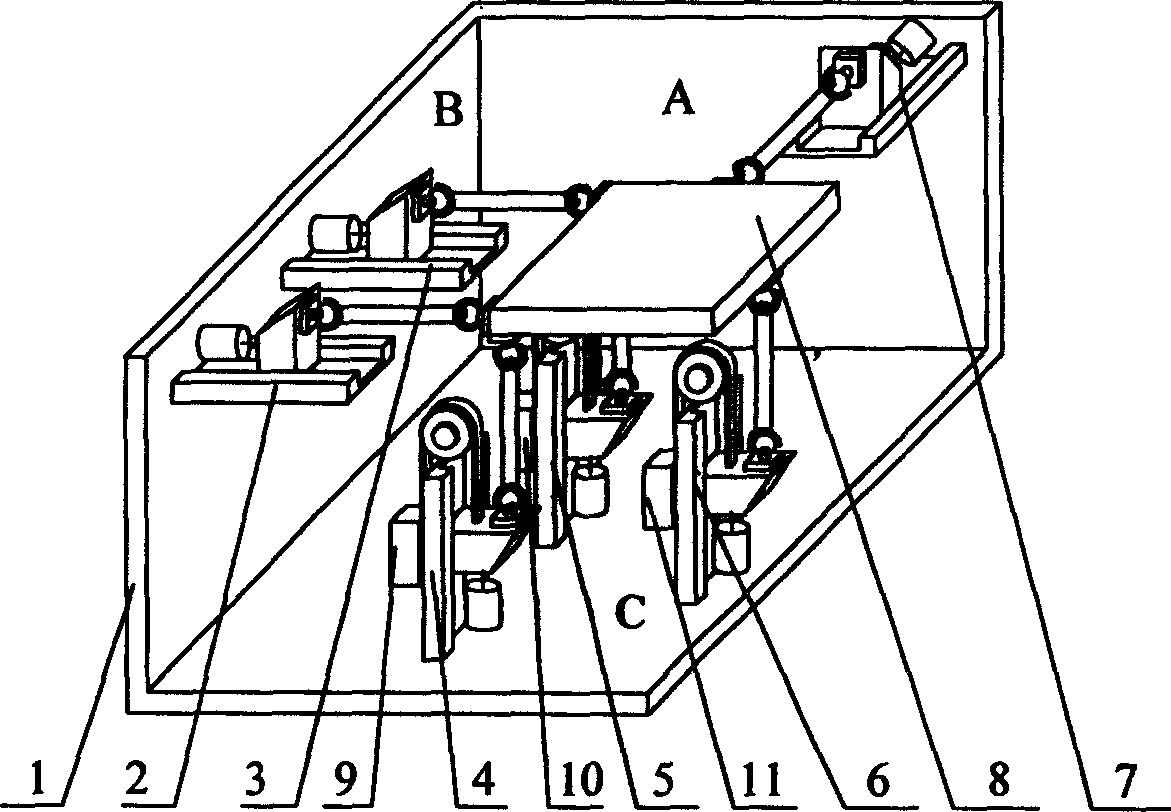

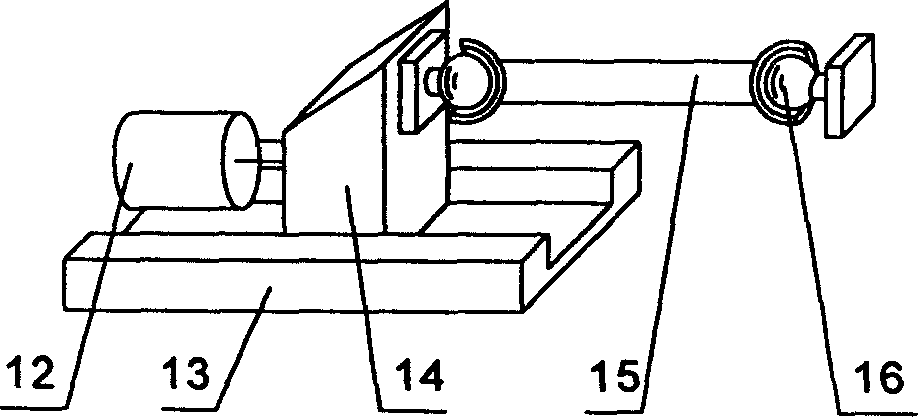

[0019] Redundant input parallel simulator of the present invention (referring to figure 1 , hereinafter referred to as the simulator), including a frame 1 composed of three mutually perpendicular panels A, B, C, a simulation platform 8 and at least three of the connection frame 1 and the simulation platform 8 respectively connected to the frame 1 three An interface module connected vertically or approximately vertically to the panels A, B, and C, and a drive device 12 connected to the interface module, characterized in that the interface module is a mechanical assembly, including a guide rail 13, a sliding table 14 matched with the guide rail 13 , a connecting rod 15 connected to one end of the slide table 14 and the simulation platform 8 with a hinge 16, and a driving device 12 connected to the other end of the slide table 14.

[0020] The simulator of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com