Respirator

A technique for breathing devices and inspiratory valves, applied in the direction of respiratory protection devices, valve devices, breathing masks, etc., which can solve problems such as prone to failure, complex mask structure, and difficulty in installing differential pressure sensors, so as to achieve less failure and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

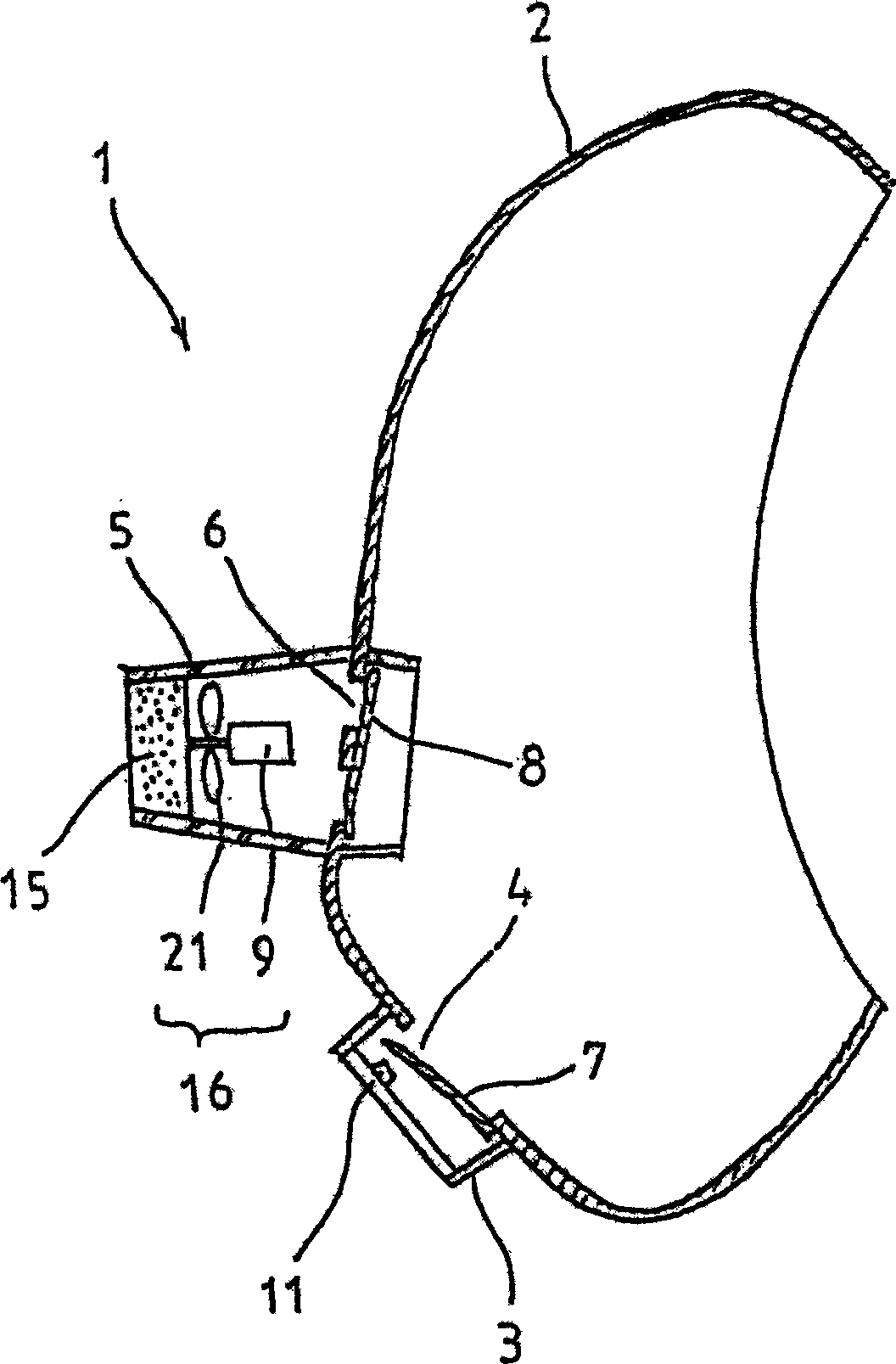

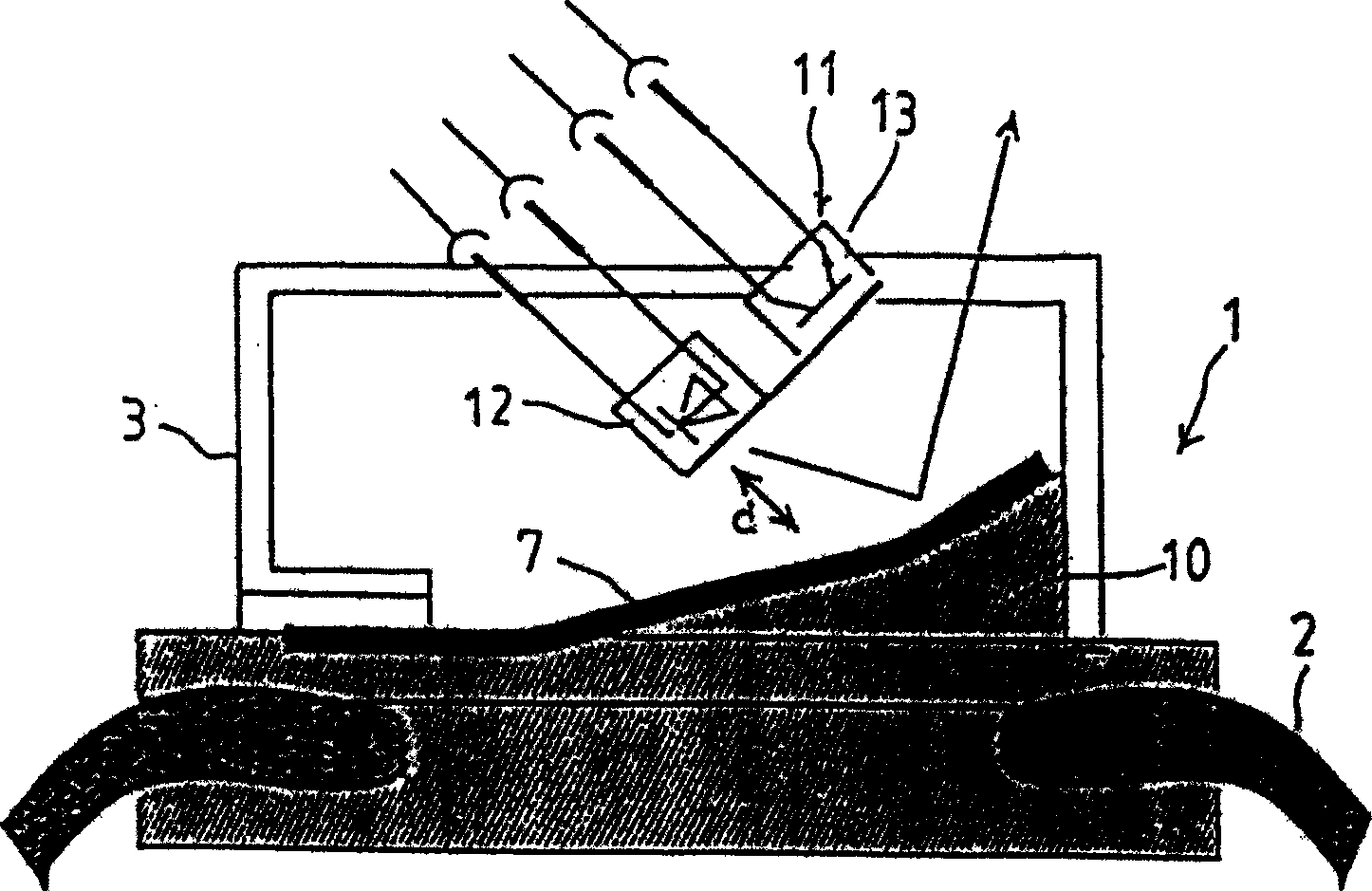

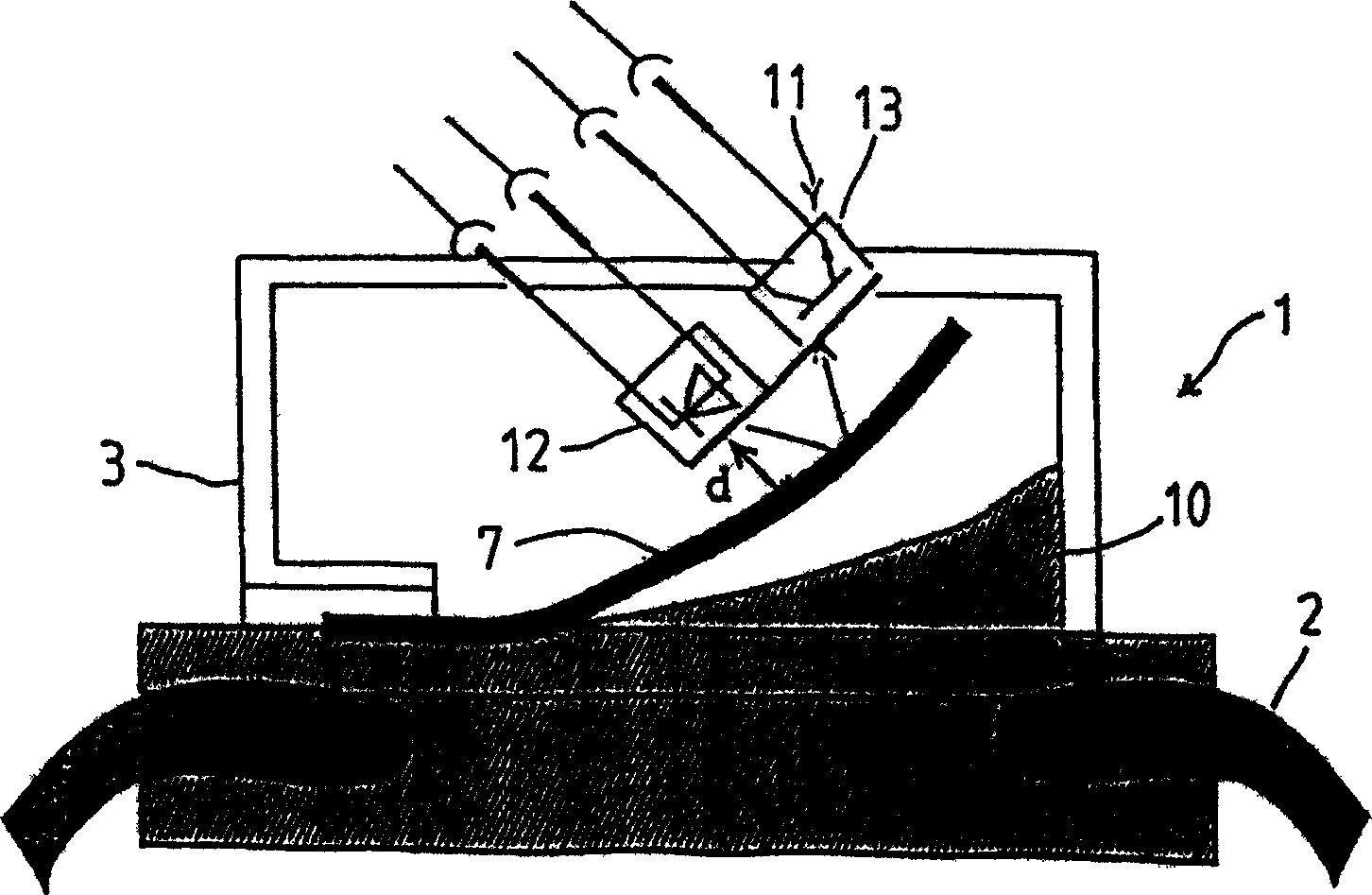

[0030] refer to Figure 1 to Figure 4 , the first embodiment of the present invention will be described.

[0031] Such as figure 1 As shown, an exhaust port 4 and an inhalation port 6 are formed on the surface body 2 of the breathing apparatus 1 . The outside of the exhaust port 4 is covered by the exhaust valve cover 3 arranged on the surface body 2 . The outside of the suction opening 6 is covered by a filter material cover 5 arranged on the surface 2 from the outside.

[0032] The exhaust port 4 is equipped with an exhaust valve 7 that is opened during exhaust and closed during suction. The suction port 6 is equipped with an air suction valve 8 that is closed during exhaust and opened during suction.

[0033] The filter material 15 and the air blower 16 are arrange|positioned at the exterior of the suction valve 8 and the inside of the filter material cover 5 in a facing posture. The blower 16 is composed of an impeller 21 and a motor 9 that drives the impeller 21 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com