Method for mfg. Y-direction antomatic oriented mask ROM

A read-only memory and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to improve memory cell margins, avoid tailing bit effects, improve memory cell margins, The effect of preventing ion diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

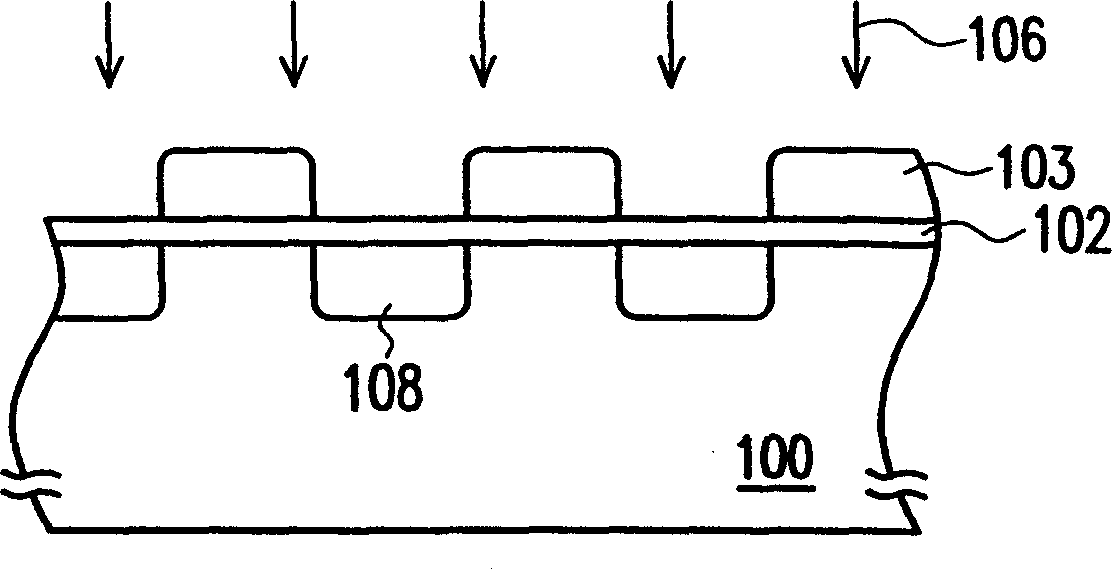

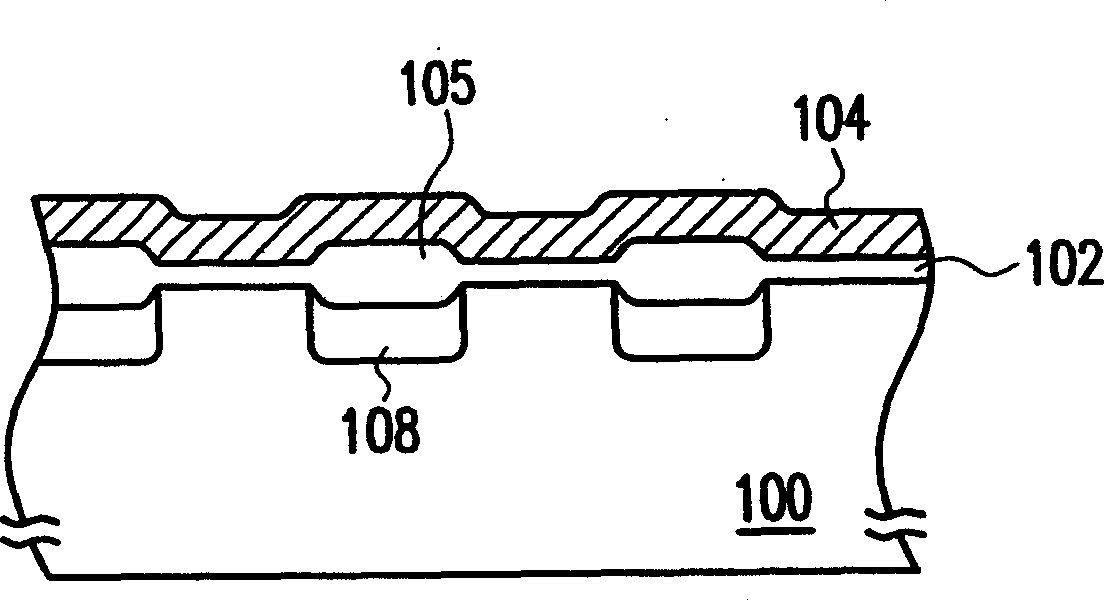

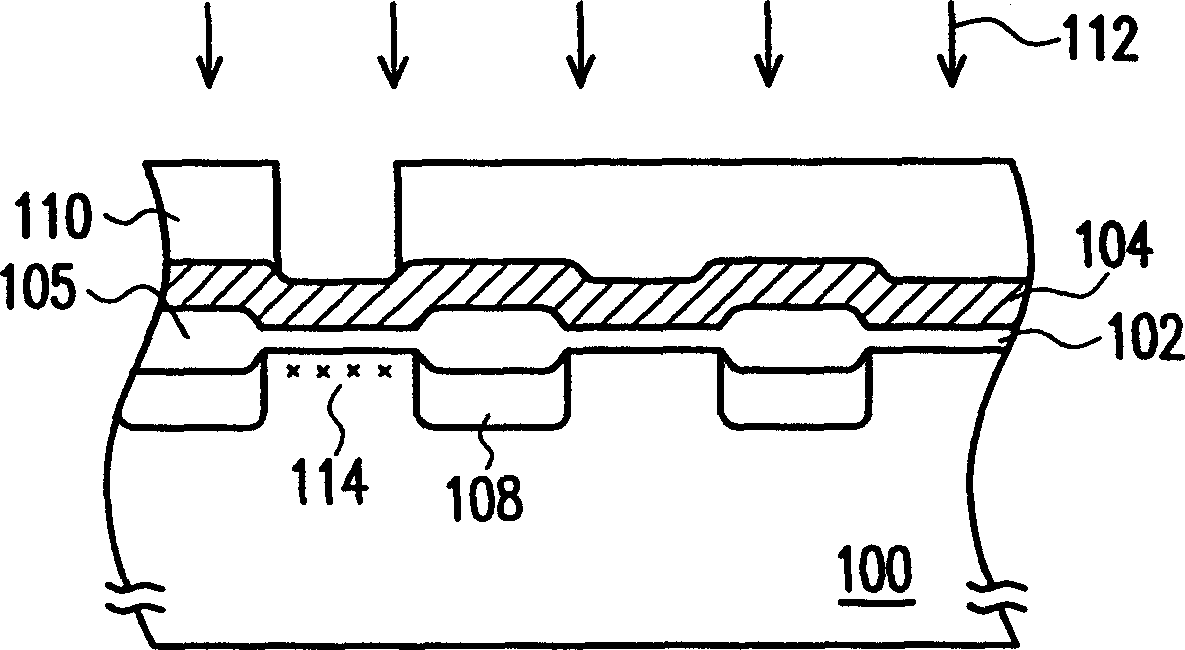

[0036] figure 2 , which is a top view of a Y-direction self-aligned mask ROM device according to a preferred embodiment of the present invention; Figure 3A to Figure 3I As shown, it is a schematic cross-sectional view of the manufacturing process of a Y-direction self-aligned mask read-only memory according to a preferred embodiment of the present invention, which is figure 2 The cross-sectional schematic diagram of X-X' and Y-Y' in the middle.

[0037] Please refer to figure 2 and Figure 3A , Figure 3A for figure 2 The cross-sectional schematic diagram of X-X' in the middle. The Y-direction self-aligned mask read-only memory manufacturing method of the present invention firstly provides a substrate 200, wherein the substrate 200 has a memory cell area 300 and a peripheral circuit area 302, and an isolation circuit has been formed in the peripheral circuit area 302 structure 201 to define an active area 204 . Here, the isolation structure 201 may be a field oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com