Vacuum processing device

A technology of vacuum treatment device and vacuum treatment chamber, which is applied in the direction of gaseous chemical plating, coating, electrical components, etc., which can solve the problems of complicated maintenance operations, reduced device work rate, and high maintenance frequency, so as to reduce the generation of dust , increase output rate, shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the vacuum processing apparatus of the present invention will be described below with reference to the drawings. In the following description and drawings, the same reference numerals are assigned to components having the same functional structure, and redundant descriptions are omitted.

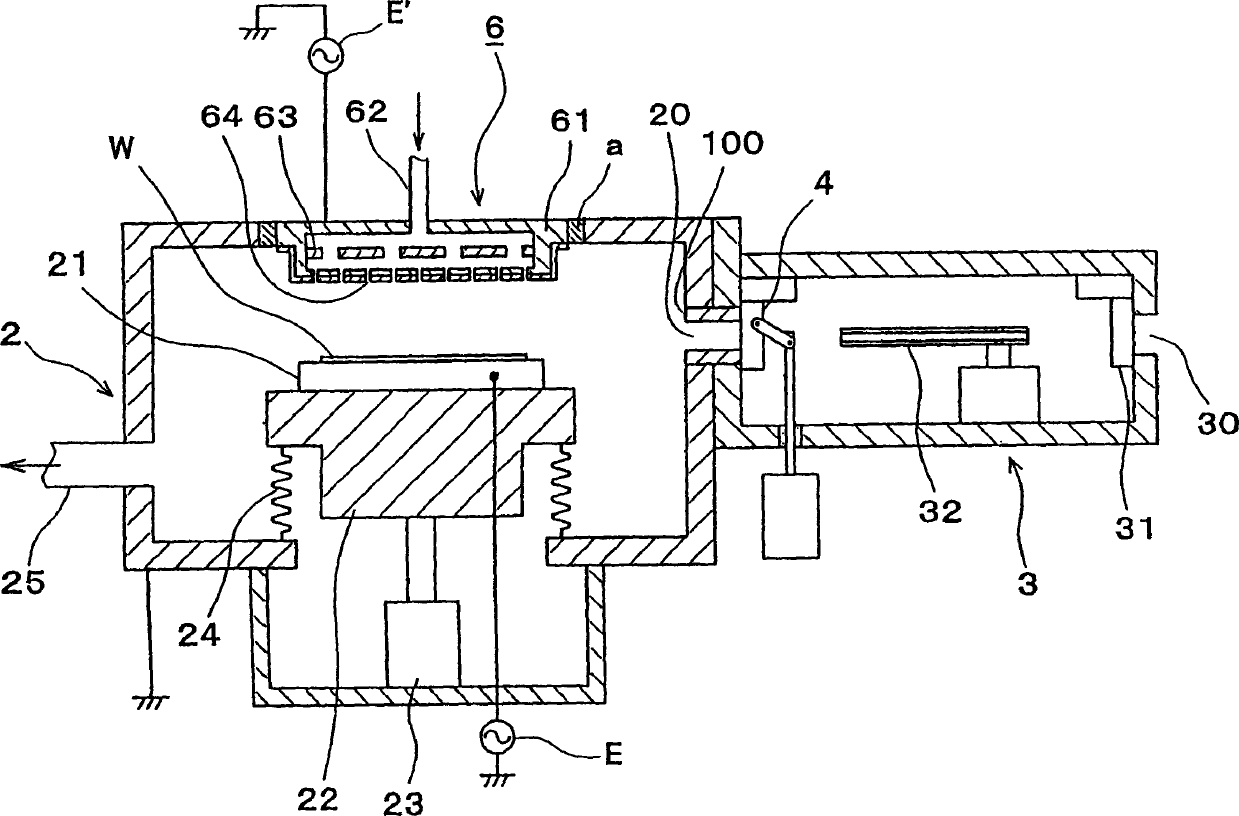

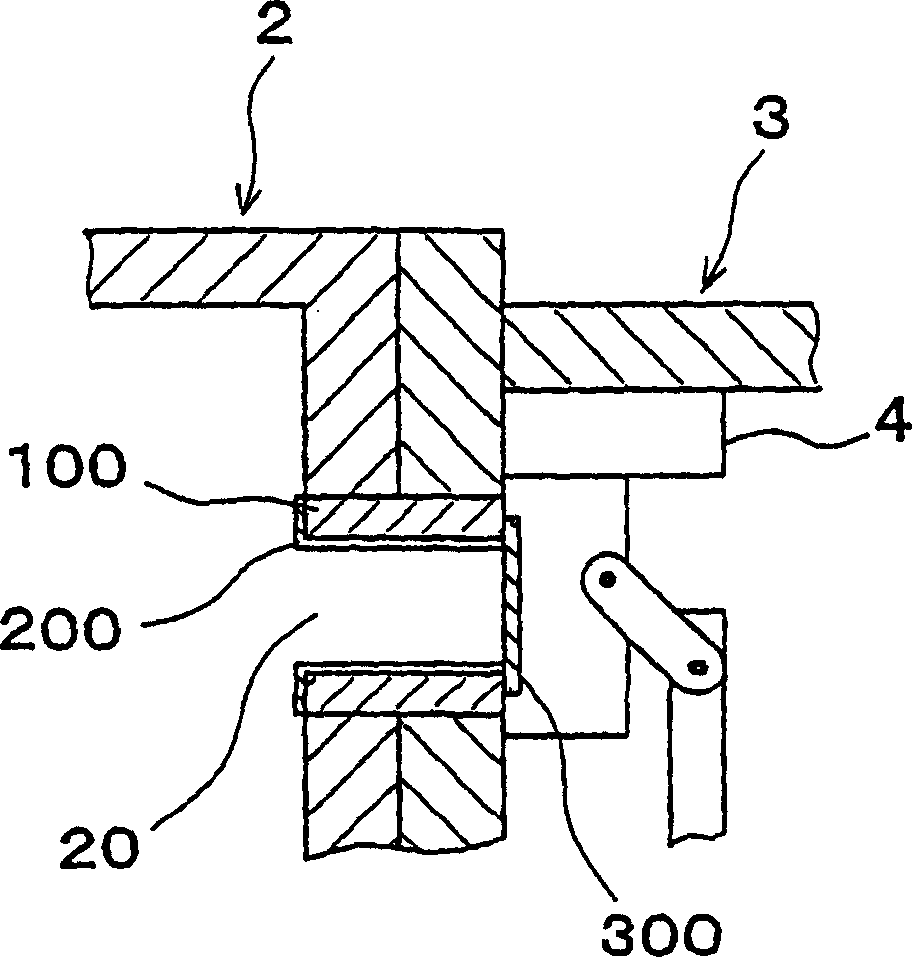

[0017] FIG. 1 is an overall configuration diagram of a vacuum processing apparatus of the present invention suitable for use in a plasma etching processing apparatus. The processing chamber 2 is a vacuum chamber with an airtight structure, and the processing chamber is grounded. The pre-vacuum chamber 3 has a load-lock function in order to prevent the inside of the processing chamber 2 from being directly exposed to the atmosphere. The processing chamber 2 and the pre-vacuum chamber 3 are connected together by a transfer port 20 formed on the chamber wall, and the wafer W is transferred through the transfer port 20 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com