Beam emittance automatic measurement and particle beam focusing automatic regualting method and apparatus

An automatic adjustment and automatic measurement technology, which is applied in radiation/particle processing, program control devices, instruments, etc., can solve the problems of unseen combination, achieve the effect of improving beam quality and reducing the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

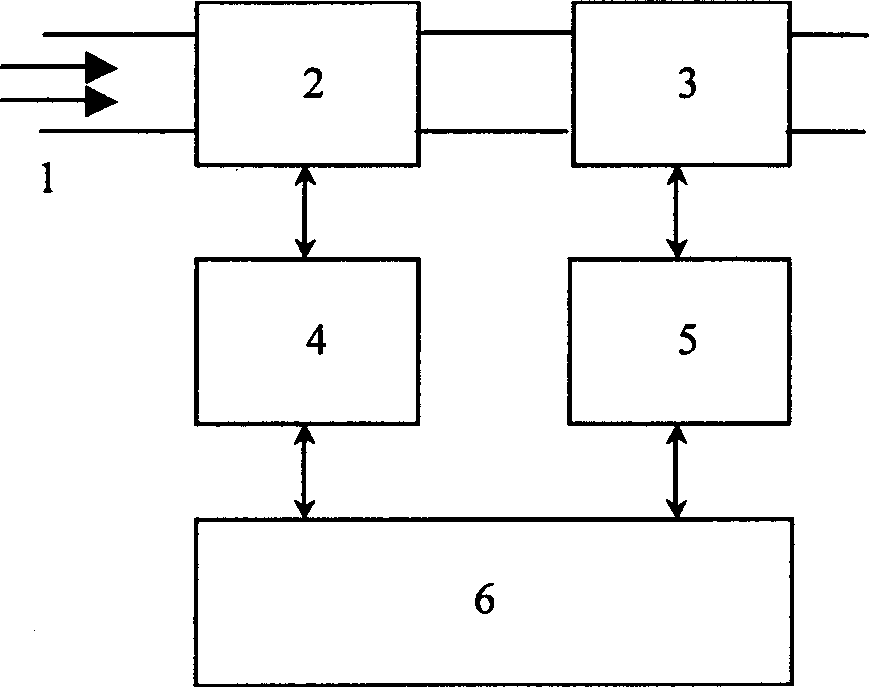

[0009] The beam emittance measurement can use the pepper screen method or the OTR method as the measuring instrument (device) [2] of the present invention, which is connected with the input data controller (device) [4], and the input data controller [4] is controlled by A / The D converter and the sensor are composed. The A / D converter converts the measured lateral emissivity electrical signal into a digital signal of the computer. The sensor receives the instructions of the computer [6] to drive the mechanical transmission to work, and drives the measuring instrument [2] ] into or out of the beam tube. The focusing lens [3] can be a quadrupole lens, a single lens, etc. It is connected with the output data controller [5], and the output data controller [5] includes a D / A converter and a sensor, and the D / A converter is a computer [6] The digital signal is converted into an electrical signal, and the electromagnetic parameters of the focusing lens are controlled by the sensor to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com