Extracting and preparing process for Echinacea prupurea and its products

A technology of echinacea purpurea extract and extraction process, which is applied in medical preparations containing active ingredients, separation/purification of carboxylic acid esters, organic chemistry, etc., can solve the problems that the extraction process of echinacea purpurea extract has not been reported, and achieve low cost , production safety, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

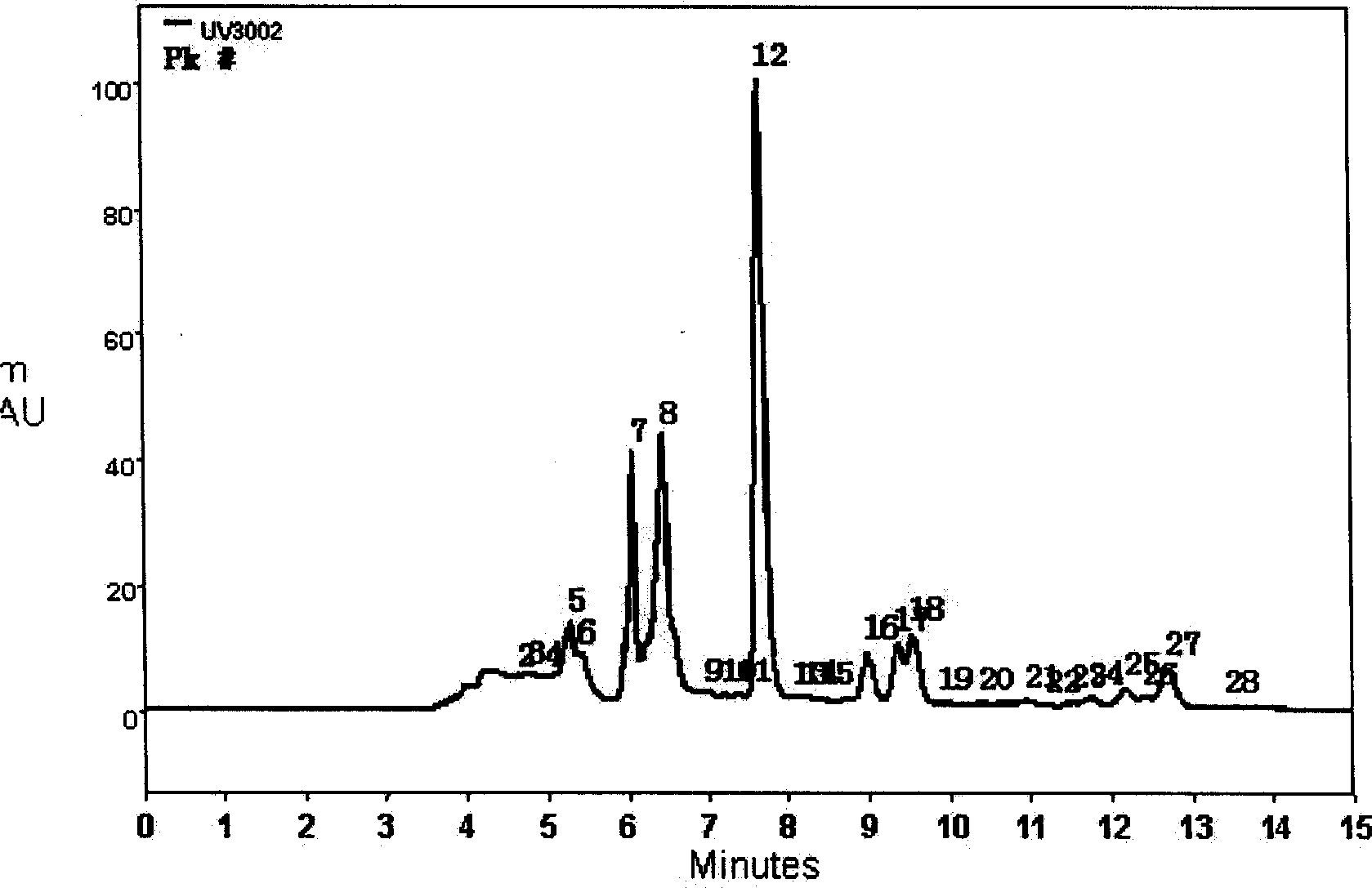

[0018] Take 20 grams of Echinacea plant powder as raw material, place it in a round-bottomed flask, add 10 times (ie 200ml) 30% ethanol solution (add quantitative enzyme inhibitor), place on a water bath, reflux and extract at 55℃ After 2 hours, the filtrate and residue were collected after filtration. Then add 10 times the 30% ethanol solution to the residue, reflux and extract for 2 hours under the same conditions, then filter, and combine the two filtrates. Place the filtrate at 4°C for 24 hours, then filter to remove the precipitate, and then pass through a 0.45um microporous membrane to remove bacteria and macromolecular proteins. The filtrate from which the protein has been removed is placed on a rotary evaporator, concentrated by rotary evaporation at 50°C, and concentrated until thick and strong, and then evaporated to a paste in a water bath at 70°C. Finally, the concentrated extract is placed in a vacuum drying oven and dried under vacuum at 50-60°C. The brown solid extr...

Embodiment 2

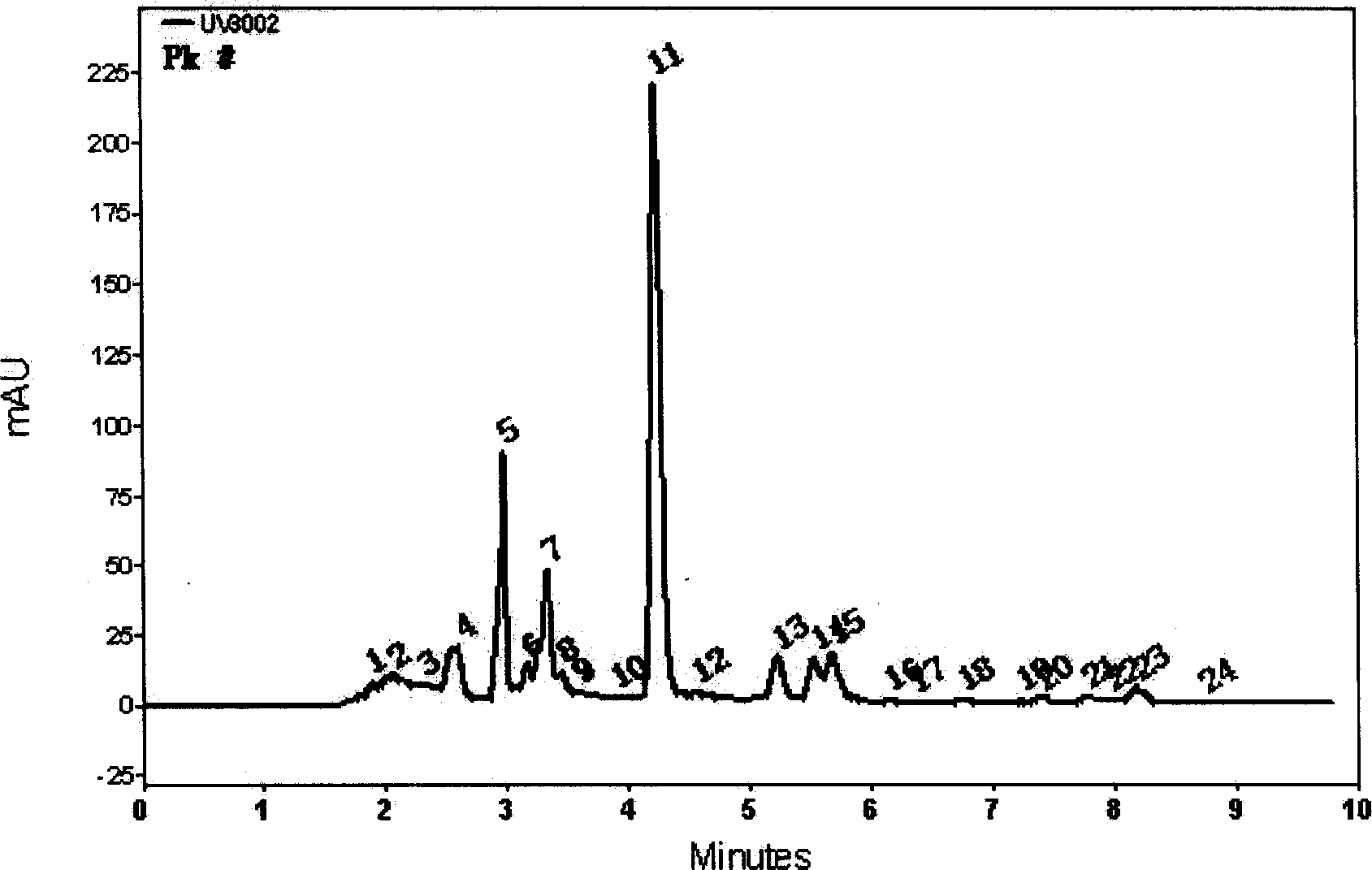

[0020] Take 20 grams of Echinacea plant powder as raw material, place it in a round-bottomed flask, add 15 times (ie 300ml) 40% ethanol solution, place it on a water bath, reflux and extract at 70℃ for 4 hours, filter and collect the filtrate and Residue. Then add 15 times the 40% ethanol solution to the residue, reflux and extract for 4 hours under the same conditions, then filter, and combine the two filtrates. Place the filtrate at 4°C for 24 hours, then filter to remove the precipitate, and then pass through a 0.45um microporous membrane to remove bacteria and macromolecular proteins. The filtrate from which the protein has been removed is placed on a rotary evaporator, concentrated by rotary evaporation at 50°C, and concentrated until thick and strong, and then evaporated to a paste in a water bath at 70°C. Finally, the concentrated extract is placed in a vacuum drying oven and dried under vacuum at 50-60°C. The brown solid extract can be obtained. The extract is dissolved, a...

Embodiment 3

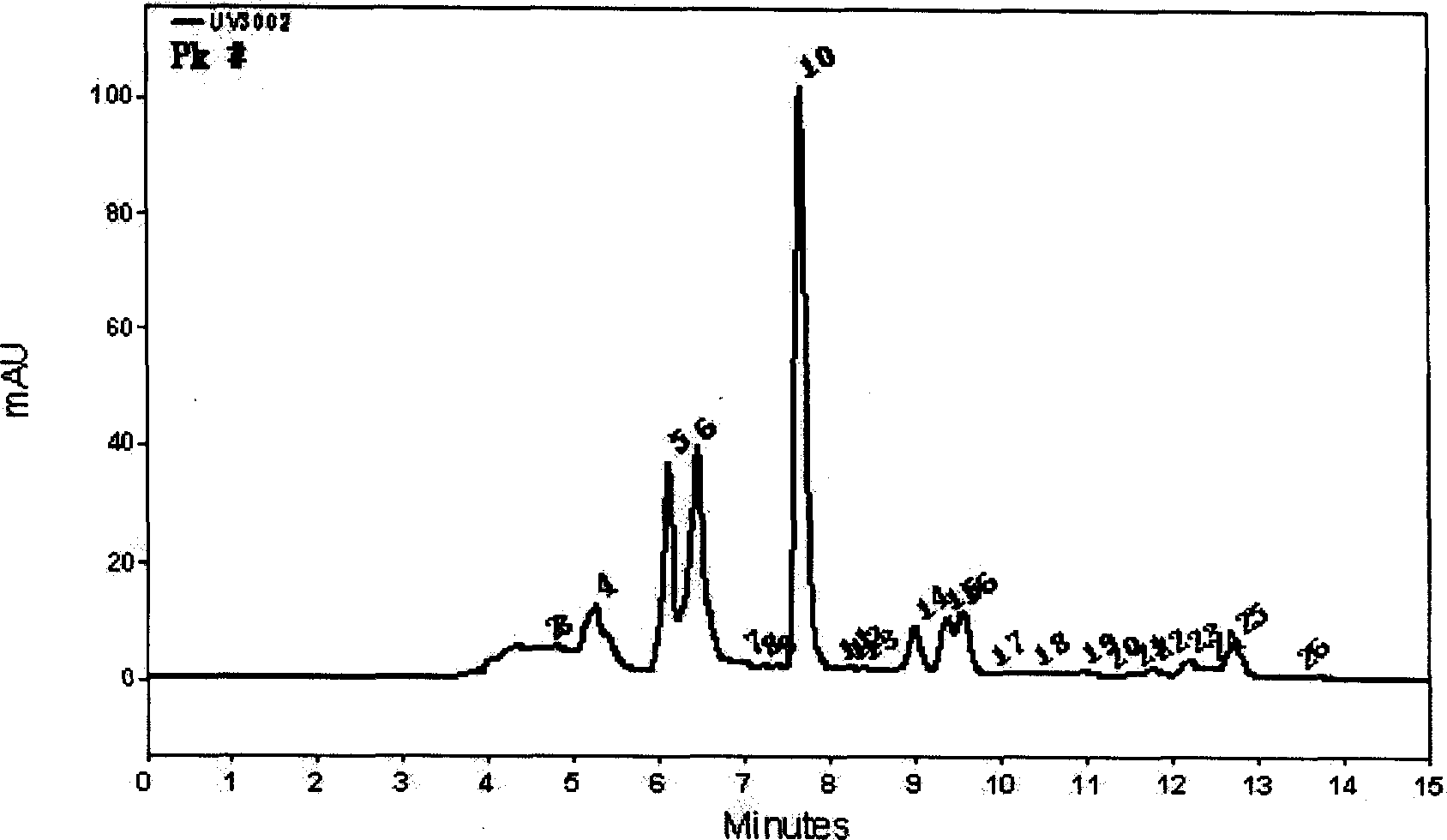

[0022] Take 20 grams of Echinacea plant powder as raw material, place it in a round bottom flask, add 15 times (ie 300ml) 80% ethanol solution, place it on a water bath, reflux for 2 hours at 55℃, collect the filtrate and Residue. Then add 15 times the 80% ethanol solution to the residue, reflux and extract for 2 hours under the same conditions, then filter, and combine the two filtrates. Place the filtrate at 4°C for 24h, then filter to remove the precipitate, and then pass through a 0.45um microporous membrane to remove bacteria and macromolecular proteins. The filtrate from which the protein has been removed is placed on a rotary evaporator, concentrated by rotary evaporation at 50°C, and concentrated until thick and strong, and then evaporated to a paste in a water bath at 70°C. Finally, the concentrated extract is placed in a vacuum drying oven and dried under vacuum at 50-60°C. The brown solid extract can be obtained. The extract is dissolved, and the analysis result of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com