Method of forming word wire of semiconductor

A semiconductor and device technology, applied in the field of word lines forming semiconductor devices, can solve problems such as charge loss and lower refresh characteristics of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail with reference to the drawings.

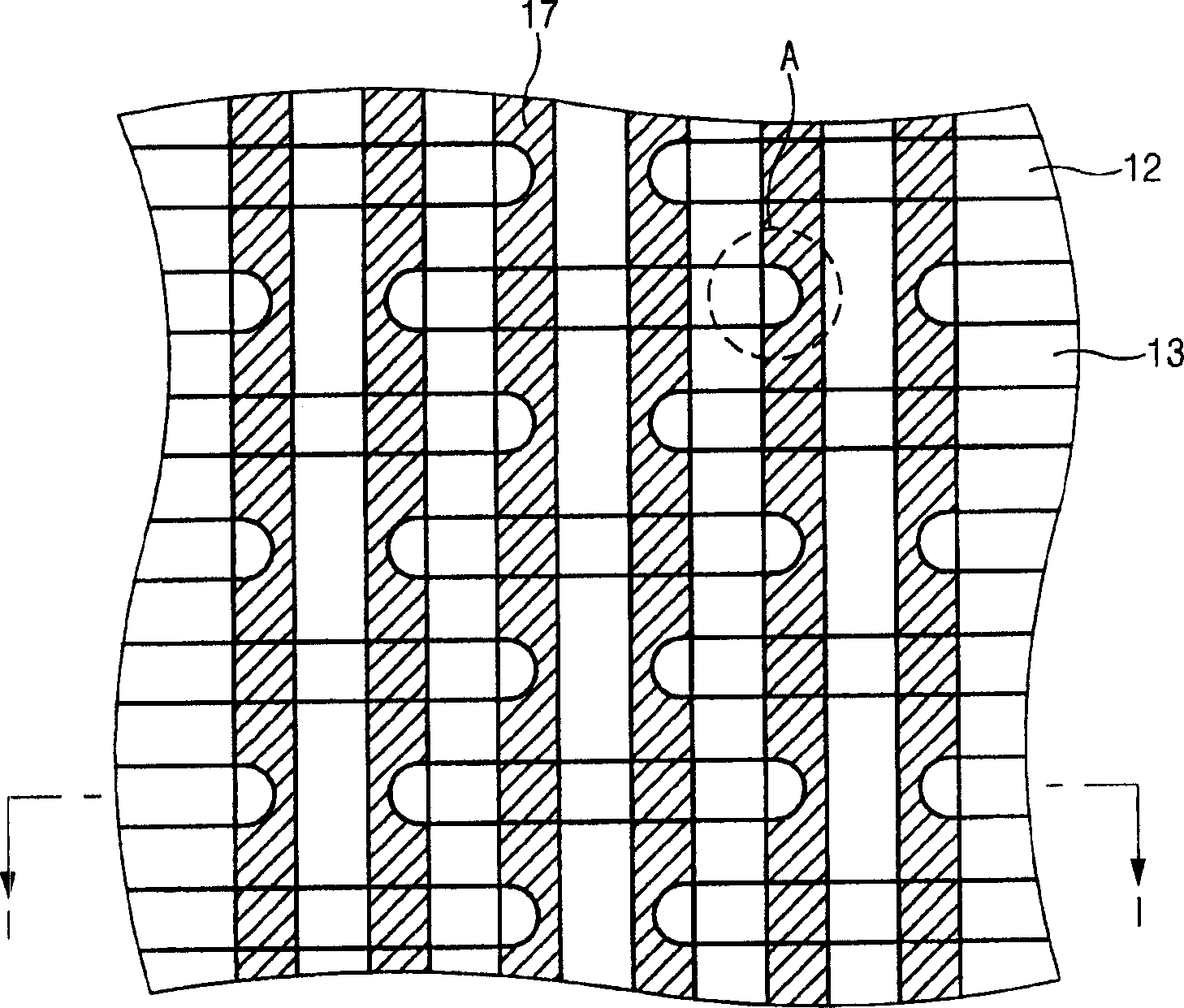

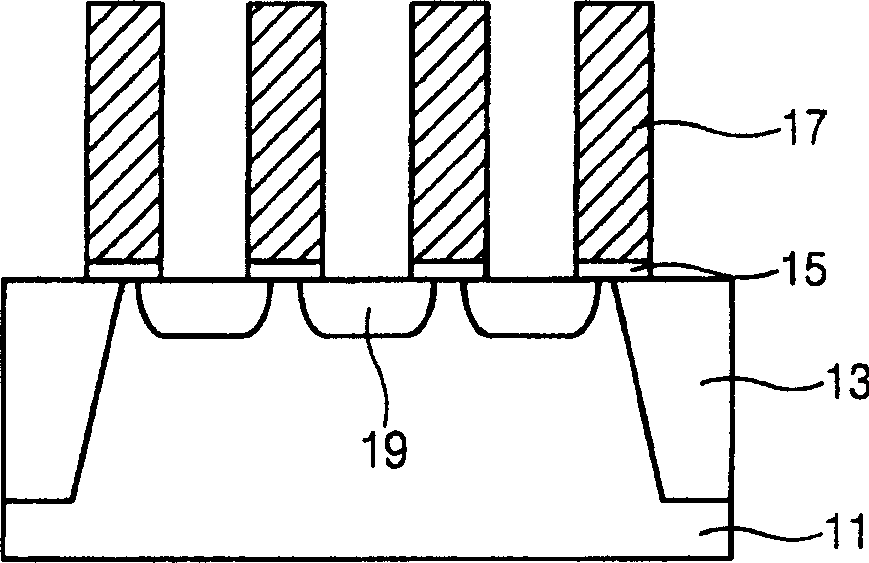

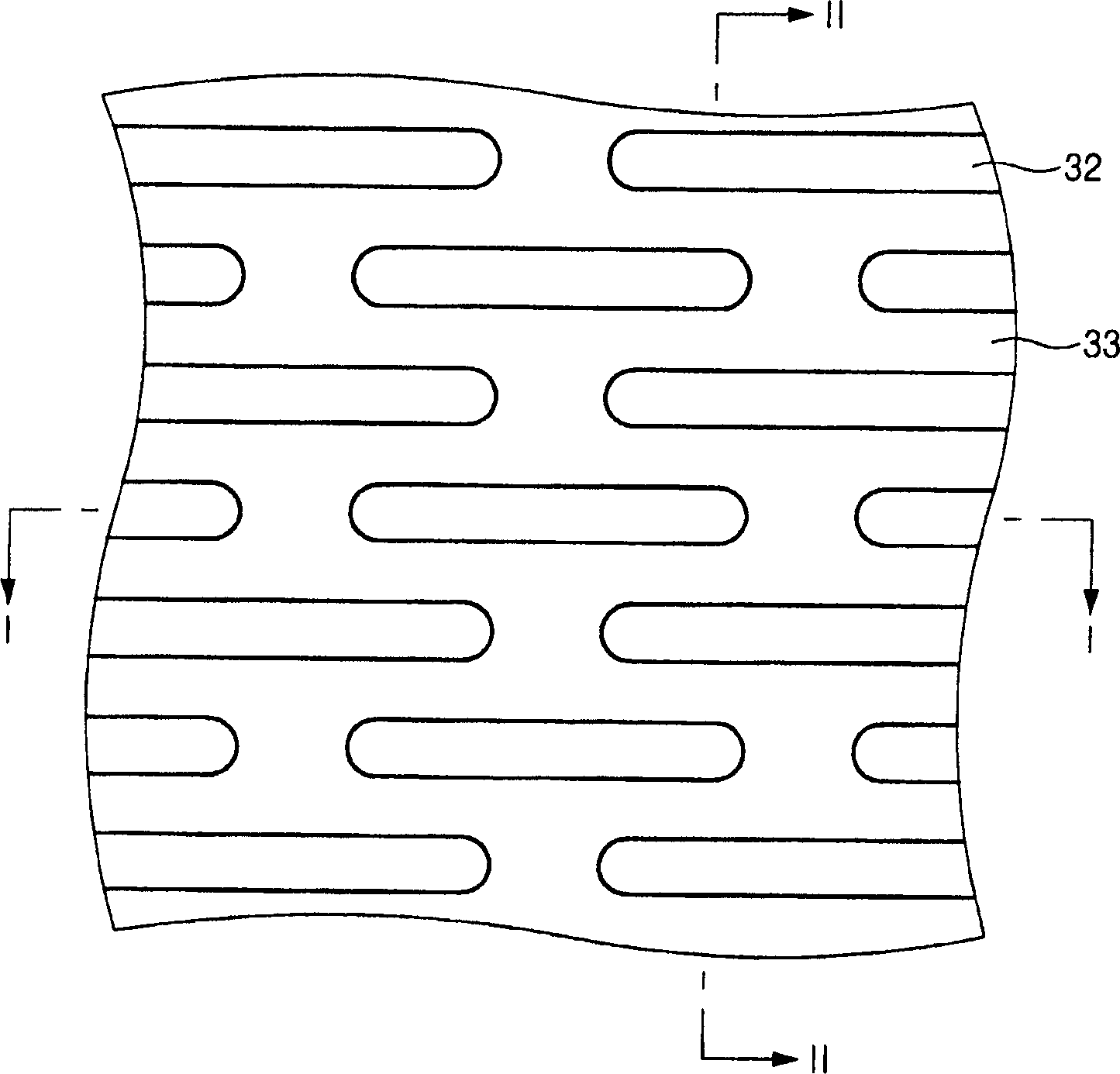

[0020] Figures 3a to 3d is a layout diagram showing a method of forming word lines according to an embodiment of the present invention. Figures 4a to 4d are along Figures 3a to 3d Sectional view of lines I-I and II-II.

[0021] refer to Figure 3a and 4a The device isolation film 33 defining the I-type active region 32 is formed by performing a shallow trench isolation process in the device isolation region of the p-type semiconductor substrate 31 . The active regions 32 are separated from each other by a predetermined distance in the horizontal direction, and are staggered in the vertical direction.

[0022] refer to Figure 3b and 4b , a sacrificial insulating film (not shown), preferably a nitride film, is formed on the semiconductor substrate 31 . The sacrificial insulating film is selectively etched to form an I-type sacrificial insulating film pattern 35 on a predetermin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com