Method for quantifying texture homogeneity of polycrystalline material

A material, incremental technique applied to measuring devices, material analysis using radiation diffraction, instrumentation, etc., capable of solving problems such as inconsistencies in interpretation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

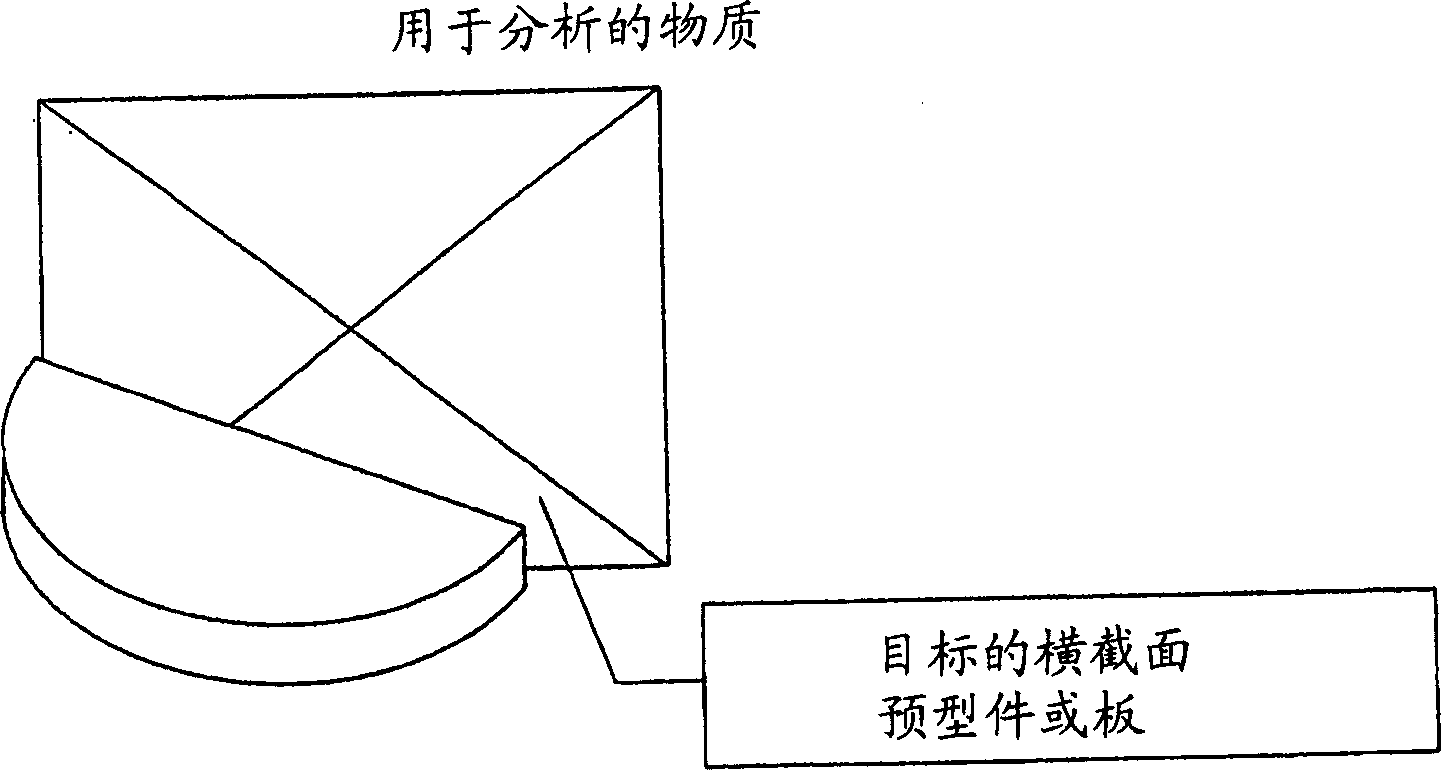

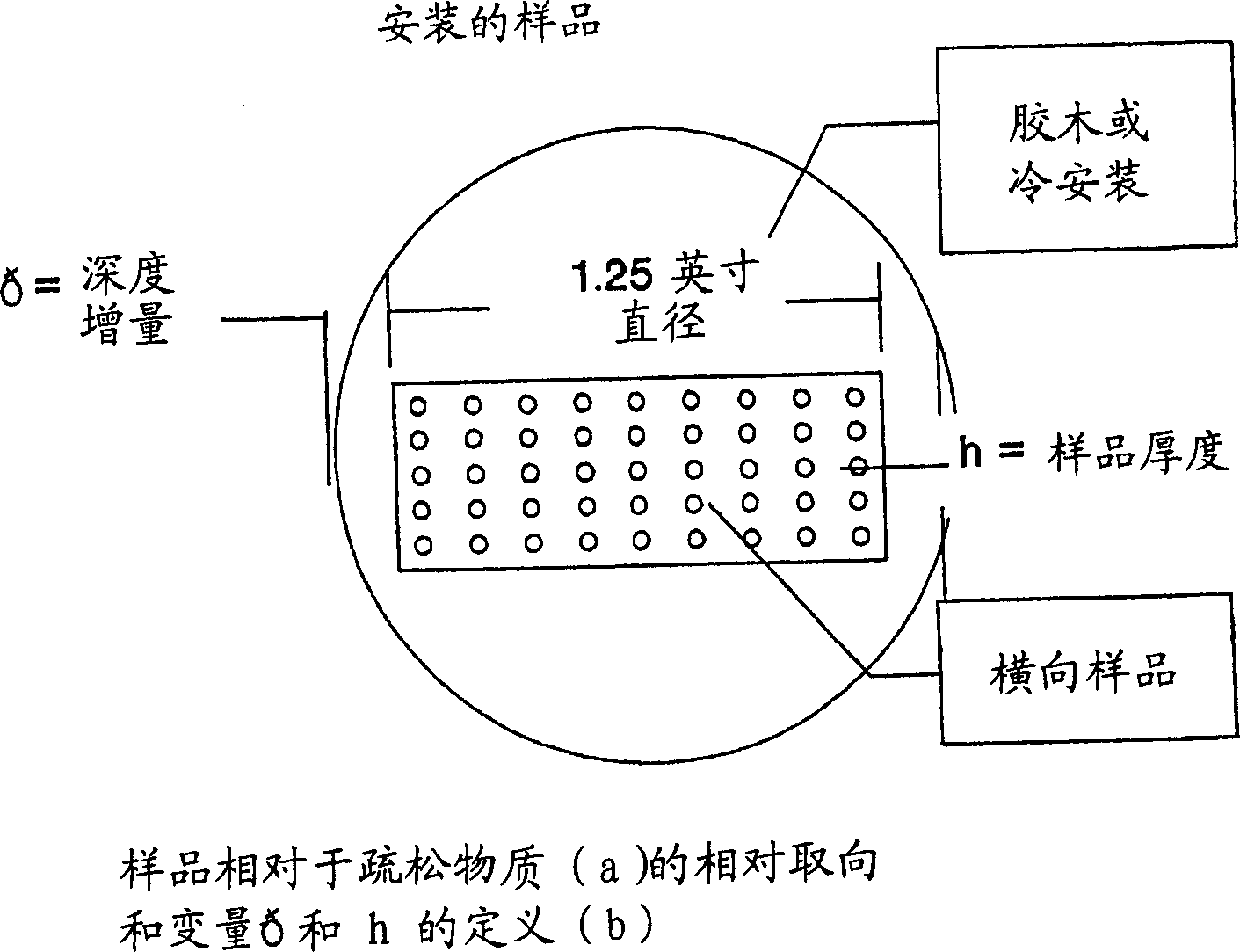

[0049] This experiment was performed to illustrate the relationship between microstructure and structural inhomogeneity in a poor metallurgical quality tantalum plate. Sputter target grade wrought and recrystallized 0.25" thick tantalum plates are commercially available. Their chemical, metallurgical and mechanical properties are shown in Table 1. From about 0.5" from the sheared edge of the plate " or more area to take a sample of approximately 0.25" x 1.0" x 0.5". Mount the sample, grind, polish and etch a cross-section of the sample. The structural sample is carried out according to the method described in the following literature Prepared by: C.A. Michaluk, C. Heubeck, and H. Klein, Methods for Edtermining the Global Texture of Tantalum Plate Using X-Ray Diffraction, Tantalum , (E.Chem.et al.eds), TMS, Warrendale, PA (1996) pp 123-131, all incorporated herein by reference, except that the polished samples were painted with a 50% HF-50%HNO 3 Reagent grade solution was us...

Embodiment 2

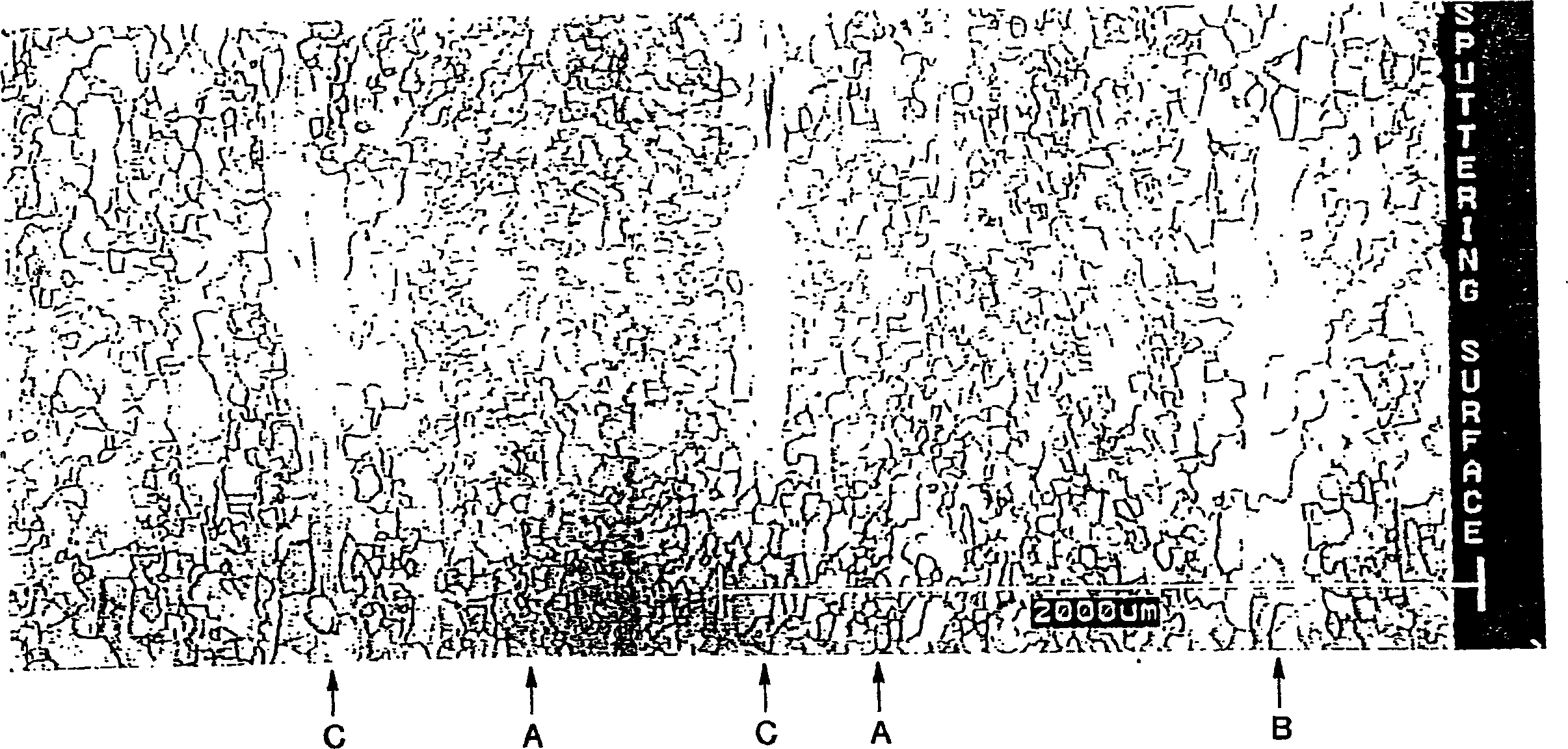

[0093] This analysis was used to determine the Ω and Λ values of tantalum considered unacceptable for use as a sputtering target. Figure 7 Shown is a portion of a tantalum sputter target that was rejected by the user because it formed a film with unacceptable variation in the thickness direction (ie >5%). The corroded surface of the rejected object had a large area with a matte finish interspersed with areas of a shiny finish. Structural analysis showed that the matte finish contained a mixed (111)-(001) structure, while the glossy areas were almost entirely (001) structured. It is thus indicated that the matte areas represent species susceptible to sputter corrosion, whereas the shiny areas are resistant to sputter corrosion, indicating that there are localized regions of major (001) within the tantalum sputter target for sputter performance is detrimental (C.A. Michaluk, d.B. Smathers, and D.P. Field, Affect of Localized Texture on the Sputtering Performance of Tantalum,...

Embodiment 3

[0099] This example was used to determine Ω and Λ values for a tantalum sputter target with desired sputter properties and a tantalum target with edge sputter properties. The pictures of the desired and marginal sputtering targets are as follows Figure 12 and Figure 13 shown. The normal orientation IPF diagrams of the cross-sections of the target carried out from the desired and edges are as Figure 14 and Figure 15 shown. Using the method described in Example 1, samples were prepared and analyzed.

[0100] Ta target performance

[0101] According to the results of Example 2, tantalum species with Ω and Λ values lower than or equal to 74.73 / mm and 4.993 / mm, respectively, are most suitable for sputtering target applications. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com