Wide-angle and wide-spectrum reflecting membrane and its preparation method

A wide-spectrum, reflective film technology, applied in the field of reflective films, can solve the problems of easy falling off, low spectral reflectivity, and easy spectral drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

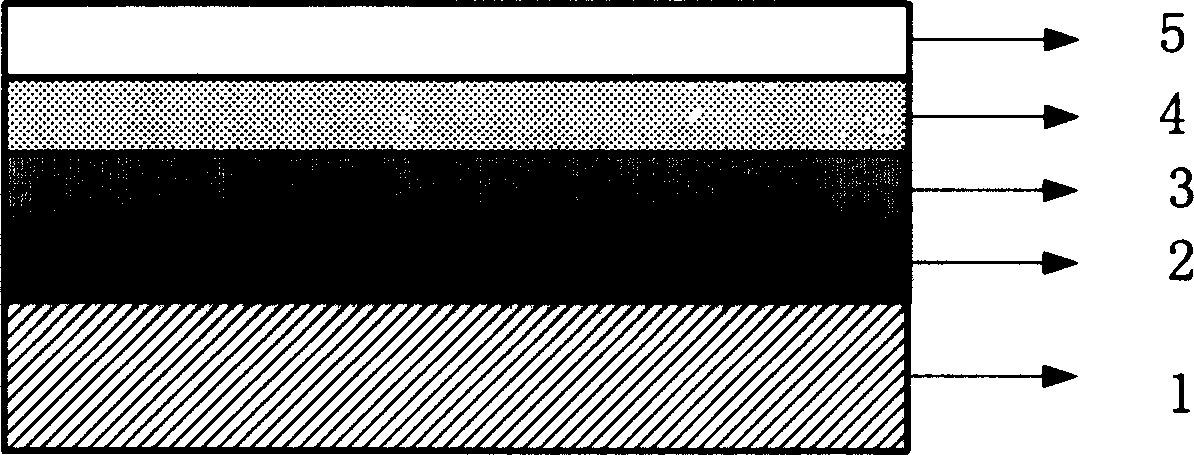

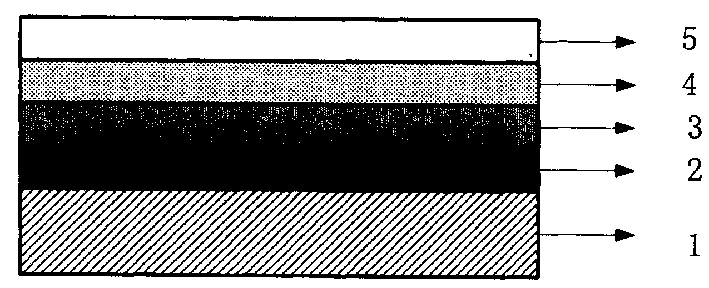

[0034] The structure of the wide-angle wide-spectrum reflective film of the present invention is as figure 1 Shown. among them

[0035] The first transition layer 2 is made of high-purity chromium (nickel, palladium, titanium) (purity 90%-100%) vapor-deposited, and the thickness is controlled between 20-100nm;

[0036] The second transition layer 3 is a mixed layer of chromium (nickel, palladium, titanium), silver (aluminum), and a film layer of a mixed material obtained by simultaneously vaporizing two materials of chromium (nickel, palladium, titanium) and silver (aluminum). The percentage ratio can be controlled in the range of 30% / 70%~70% / 30%, and the thickness of the entire film layer is between 10-100nm;

[0037] The metallic silver (aluminum) film layer 4 is vapor-deposited with a purity of more than 99.9% pure silver (aluminum), and the thickness is between 130 nm and 4000 nm;

[0038] The reinforcing film layer 5 is a combination of layers composed of high and low refract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com