Core level monitoring device for reactor

A liquid level monitoring and reactor technology, which is used in nuclear reactor monitoring, reactors, liquid level indicators for physical variable measurement, etc. , to eliminate errors and improve the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

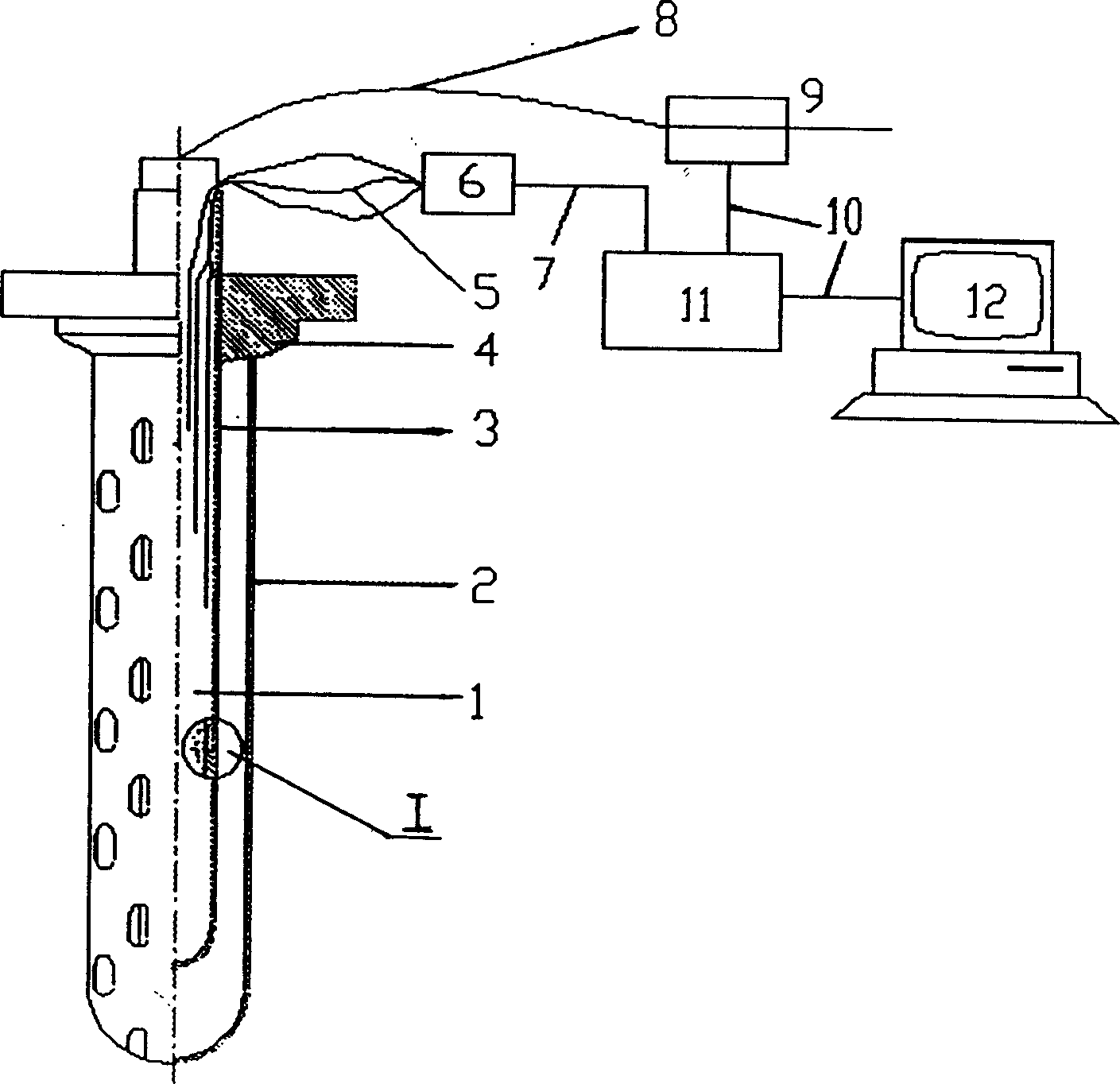

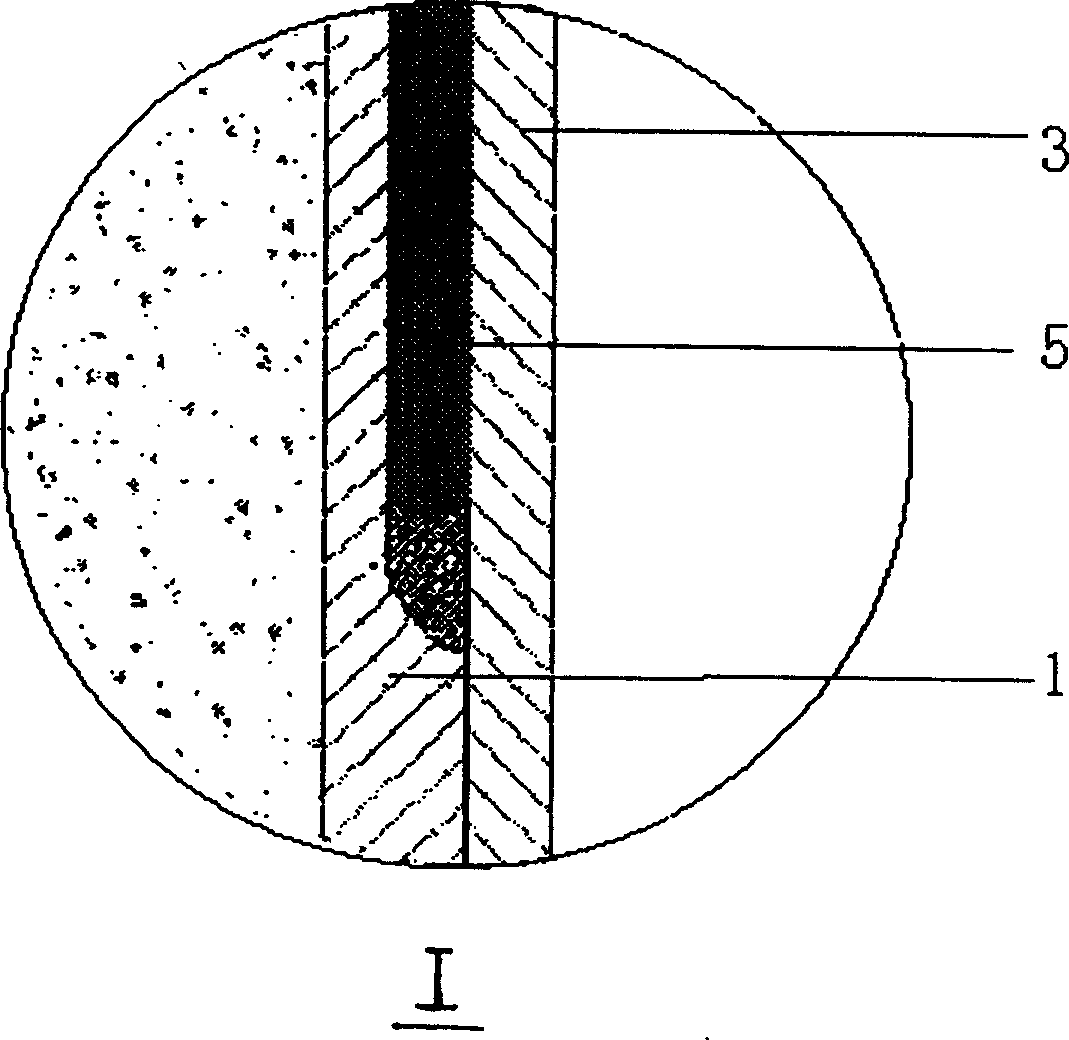

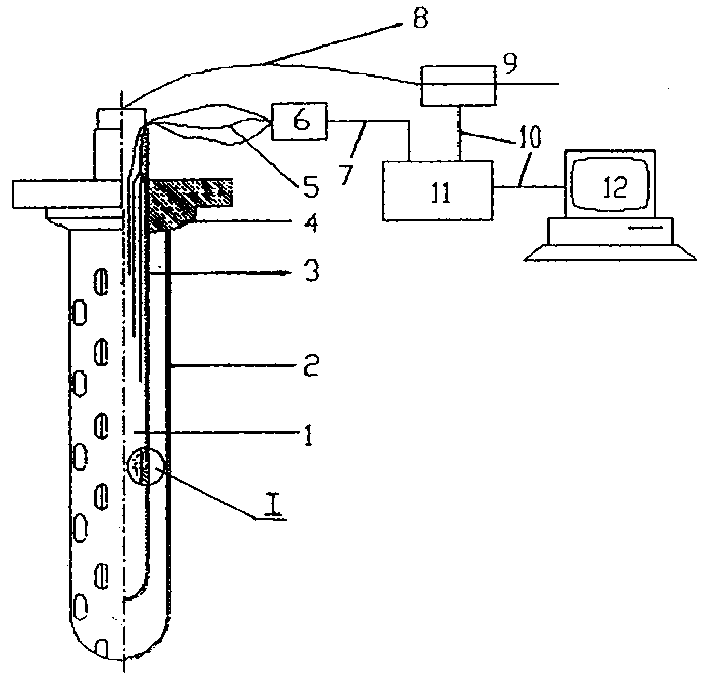

[0009] like figure 1 , figure 2 As shown, the reactor core liquid level monitoring device consists of liquid level detectors and secondary instruments. The liquid level detector is connected with the secondary instrument through the connector 6 , the compensation wire 7 and the signal cable 10 . The liquid level detector includes an electric heater 1 , a protective sleeve 2 , a thin-walled sleeve 3 , a seal 4 and a thermocouple 5 ; the secondary instrument is a computer monitoring system 12 . The liquid level detector is to process the electric heater 1 and the thermocouple 5 separately according to the given process requirements. The outer wall of the electric heater 1 is provided with longitudinal grooves of different heights, and a plurality of thermocouples 5 are respectively embedded and welded on the electric heater 1 The thermocouples are at different heights in different grooves. Then install the thin-walled casing 3 outside the processed electric heater 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com