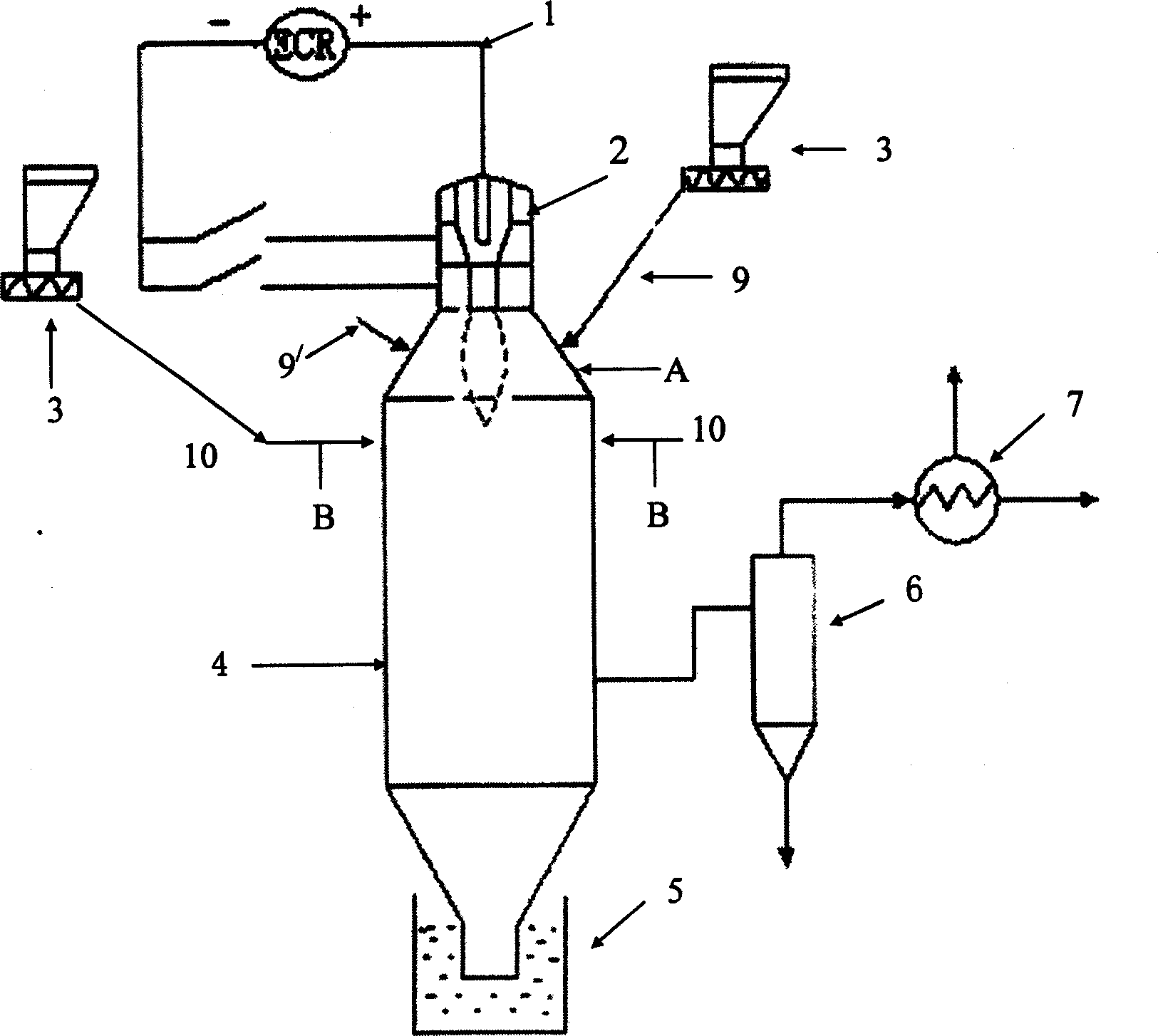

Method and device for using plasma to proceed coal gasification

A plasma and coal gasification technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry, can solve the problems of troublesome application of syngas, high content, and low calorific value, and achieve economic benefits and social considerable benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

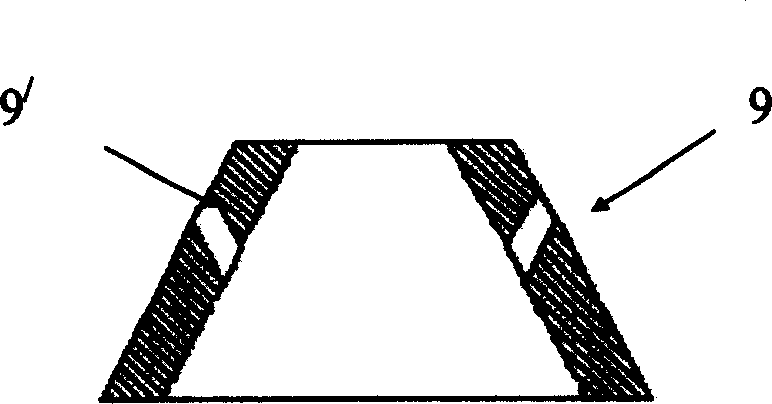

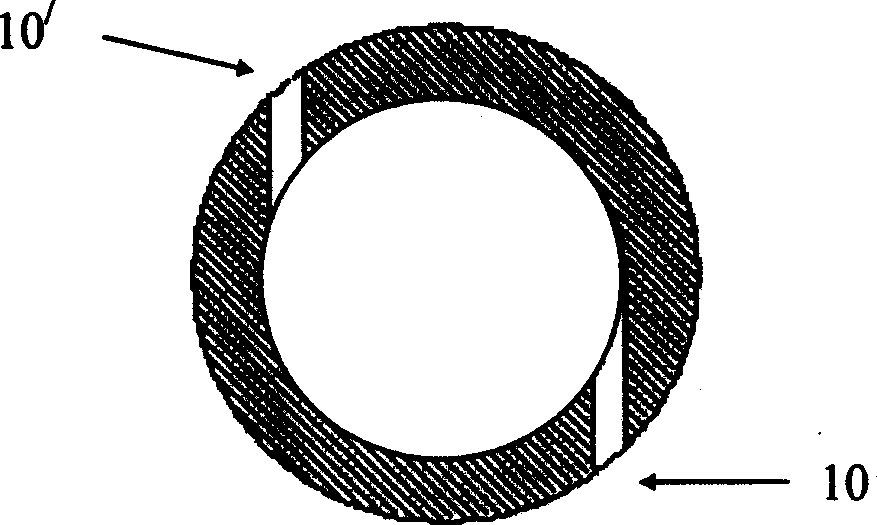

Method used

Image

Examples

Embodiment approach 1

[0030] In the plasma generator, air is introduced, and at the same time, the cooling inlet and outlet valves of the plasma generator are opened, the high-frequency ignition device is activated, and the power knob of the generator is adjusted to generate a plasma jet. When the required power is adjusted, pulverized coal and oxidant (air) are supplied according to the metering at an angle of 30 degrees to the axial direction of the gasification reactor, and the gasification reactor is heated to above 1700k°C. The flow of pulverized coal, superheated steam and oxidant used in gasification enters the gasifier from the tangential direction, the ratio of gasification pulverized coal to water vapor is 1:1, and the ratio of pulverized coal to oxidant and the output power of the plasma generator are adjusted. , keeping the system temperature at 1300k, the resulting gas composition (vol) CO 21.1% and H 2 20.5%, CO 2 The content is less than 5%.

Embodiment approach 2

[0032] In the plasma generator, air is introduced, and at the same time, the cooling inlet and outlet valves of the plasma generator are opened, the high-frequency ignition device is activated, and the power knob of the generator is adjusted to generate a plasma jet. When the required power is adjusted, pulverized coal and oxidant (air) are supplied according to the metering at an angle of 30 degrees to the axial direction of the gasification reactor, and the gasification reactor is heated to above 1750k°C. The flow of pulverized coal, superheated steam and oxidant used in gasification enters the gasifier from the tangential direction. The ratio of pulverized coal to steam is 1:1.2, and the ratio of pulverized coal to oxidant and the output power of the plasma generator are adjusted. , keeping the system temperature at 100k, the resulting gas composition (vol) CO 22.1% and H 2 21.5%, CO 2 The content is less than 4%.

Embodiment approach 3

[0034] In the plasma generator, air is introduced, and at the same time, the cooling inlet and outlet valves of the plasma generator are opened, the high-frequency ignition device is activated, and the power knob of the generator is adjusted to generate a plasma jet. When the required power is adjusted, pulverized coal and oxidant (air) are supplied according to the metering at an angle of 30 degrees to the axial direction of the gasification reactor, and the gasification reactor is heated to above 1800k°C. The flow of pulverized coal, superheated steam and oxidant used in gasification enters the gasifier from the tangential direction. The ratio of pulverized coal to water vapor is 1:1.1, and the ratio of pulverized coal to oxidant and the output power of the plasma generator are adjusted. , keeping the system temperature at 1500k, the resulting gas composition (vol) CO 20.1% and H 2 22.5%, CO 2 The content is less than 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com