Bottom brick in tin pot

A technology of tin bath bottom bricks and silica bricks, which is applied in the field of tin bath bottom bricks, can solve the problems of peeling off the upper surface of tin bath bottom bricks, reduce the resistance of tin bath bottom bricks to alkali erosion, and affect the service life of tin bath bottom bricks. To achieve the effect of prolonging the service life and strong alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

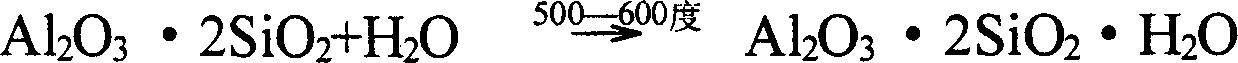

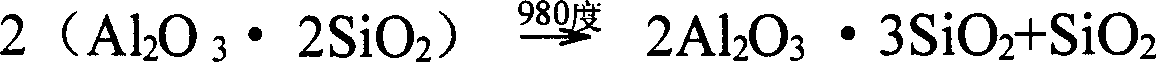

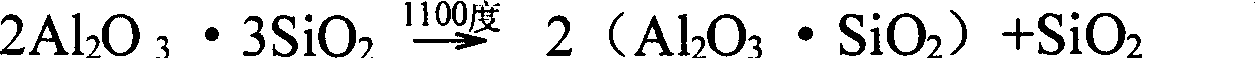

Method used

Image

Examples

Embodiment 1

[0022] The raw materials needed for the tin bath bottom brick of the present invention are prepared in the following proportions (by weight): 15 parts of aluminum-silicon clinker of 0-1mm, 10 parts of aluminum-silicon clinker of 1-3mm, and 10 parts of aluminum-silicon clinker of 3-5mm 15 parts of clinker, 20 parts of 5-8mm aluminum-silicon clinker, 20 parts of 220-250 mesh mullite powder, 5 parts of silica brick powder, 4 parts of silicon micropowder, 3 parts of high alumina cement, sodium tripolyphosphate 0.1 parts, and 6.9 parts of water. Use the high-alumina cement in the above ratio as a binder, mold it by pouring vibration, and fire it at 1300°C to obtain the tin bath bottom brick of the present invention.

Embodiment 2

[0024] The raw materials required for the tin bath bottom brick of the present invention are prepared in the following proportions (by weight): 17 parts of aluminum-silicon clinker of 0-1mm, 12 parts of aluminum-silicon clinker of 1-3mm, and 12 parts of aluminum-silicon clinker of 3-5mm 20 parts of clinker, 25 parts of 5-8mm aluminum-silicon clinker, 22 parts of 220-250 mesh bauxite powder, 7 parts of sandstone powder, 5 parts of silica powder, 4 parts of high alumina cement, sodium tripolyphosphate It is 0.2 parts, and water is 6.8 parts. Use the high-alumina cement in the above ratio as a binding agent, mold it by pouring vibration, and fire it at 1325°C to obtain the tin bath bottom brick of the present invention.

Embodiment 3

[0026] The raw materials required for the tin bath bottom brick of the present invention are prepared in the following proportions (by weight): 20 parts of aluminum-silicon clinker of 0-1mm, 15 parts of aluminum-silicon clinker of 1-3mm, and 15 parts of aluminum-silicon clinker of 3-5mm 25 parts of clinker, 30 parts of 5-8mm aluminum-silicon clinker, 25 parts of 220-250 mesh clay powder, 5 parts of kyanite, 6 parts of silicon micropowder, 5 parts of high alumina cement, and 5 parts of sodium tripolyphosphate 0.05 parts, water is 7.5 parts. Use the high-alumina cement in the above ratio as a binding agent, mold it by pouring vibration, and fire it at 1350°C to obtain the tin bath bottom brick of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com