High density heat exchange duct device

A duct device and dense technology, applied in the field of high-density heat exchange duct devices, can solve the problem that the area and time of air and heat dissipation fins cannot be effectively extended, the speed of contact between air and the surface of heat dissipation fins cannot be improved, and the air heat exchange efficiency is effective. Play and other problems, to achieve the effect of outstanding heat dissipation efficiency, wide application range and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

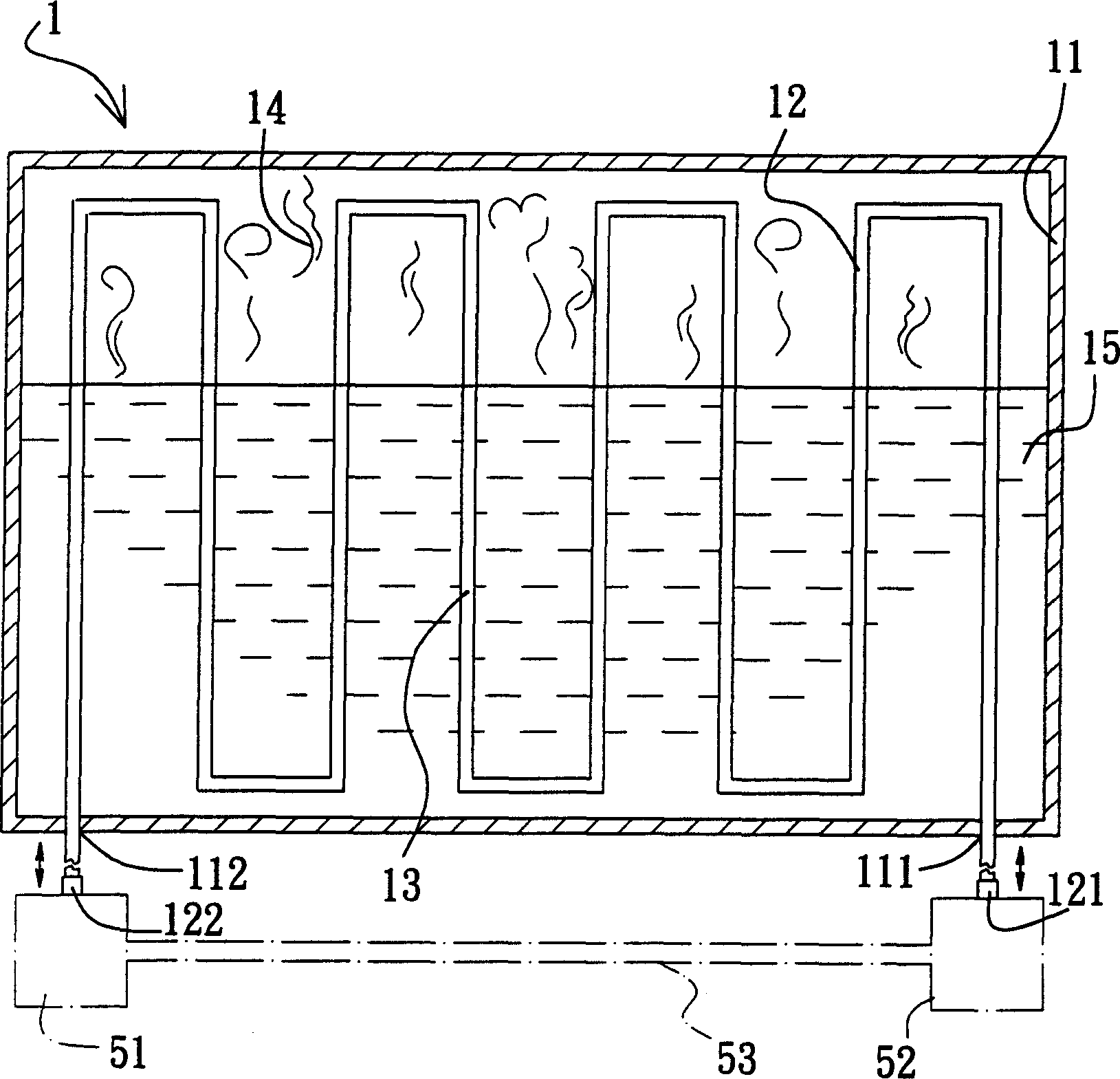

[0032] Such as figure 1 , 2 As shown, the high-density heat exchange conduit device 1 of the first embodiment of the present invention includes a heat conduction shell 11 and a heat conduction tube 12 wound in the heat conduction shell 11 in a convoluted manner and processed with metal materials. The heat conduction shell 11 can be a closed hollow shell, which has an outlet 111 and an inlet 112, and the heat conduction shell 11 can be made of metal heat conduction materials such as copper, aluminum or silver, and can also be made of polymer materials or Non-metal thermal conductive materials such as ceramic composite materials.

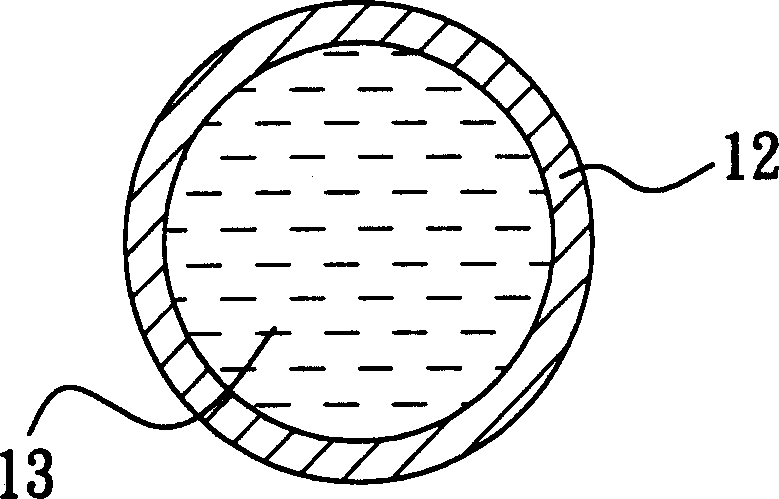

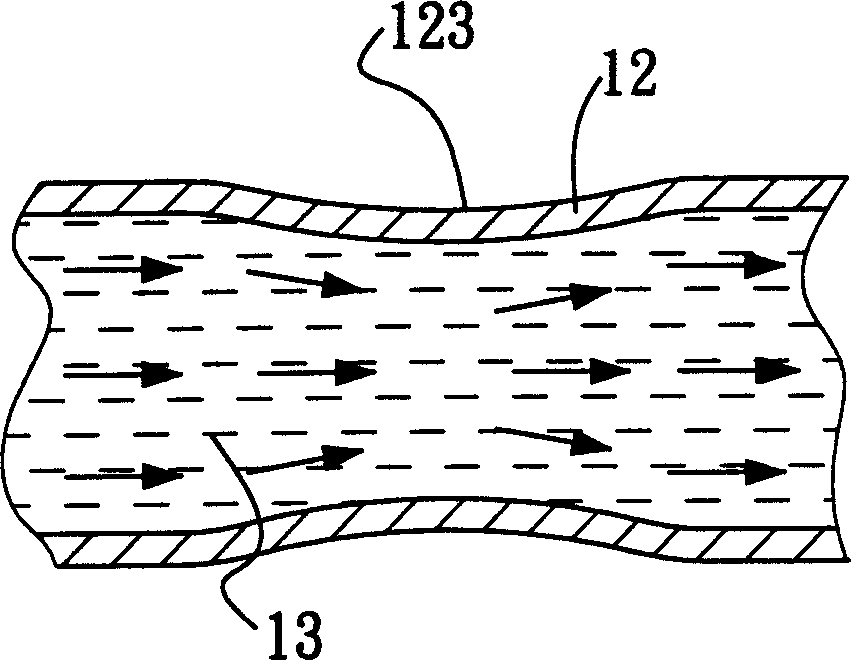

[0033] The heat pipe 12 can be a hollow pipe body made of a metal material with high thermal conductivity, and it can be processed by more than one mechanical method to form a wire-wound conduit group of required specifications or made by a wire spring forming process. Of course, graphite-like carbon-based materials with high thermal conductivity, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com