Micro-array protein chip and making method thereof

A protein chip and microarray technology, applied in material testing products, instruments, analytical materials, etc., can solve the problems of high cost, only a few detection units, complicated preparation process, etc., and achieve the effect of no labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

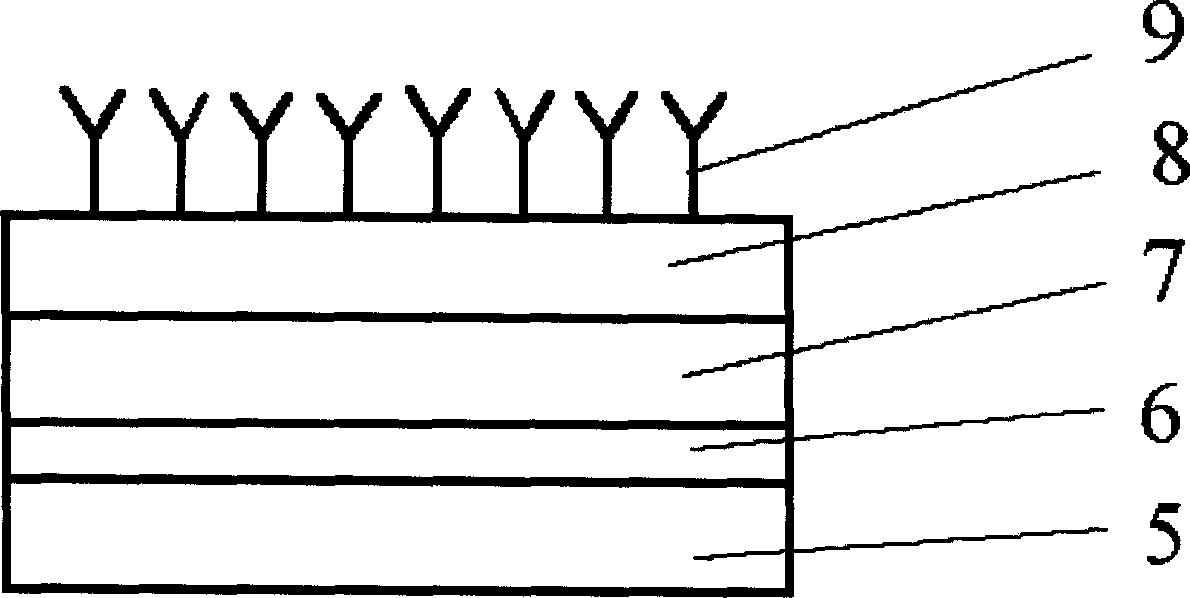

[0031] The microarray protein chip and its manufacturing method according to the present invention will be described in detail below in conjunction with the accompanying drawings.

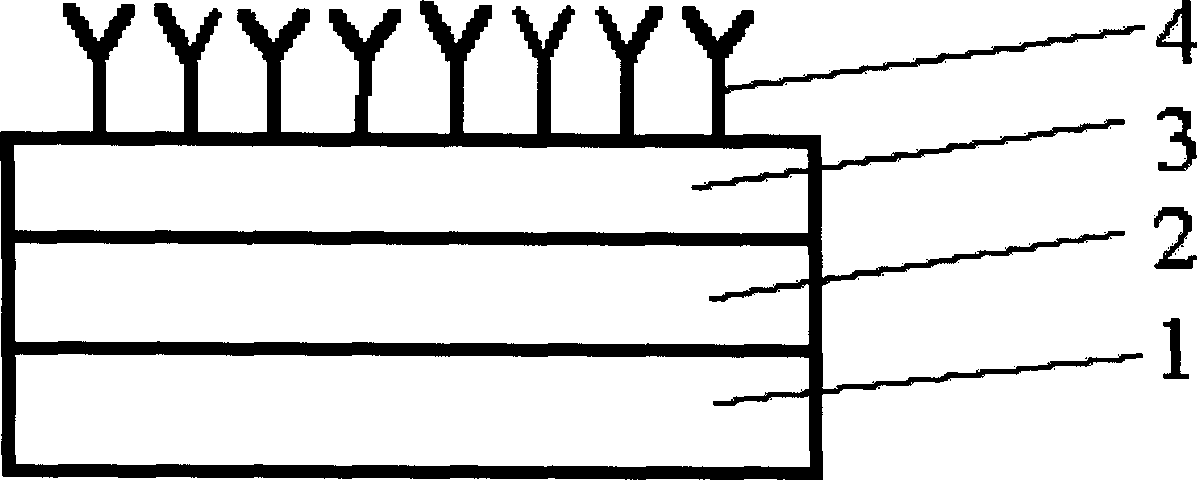

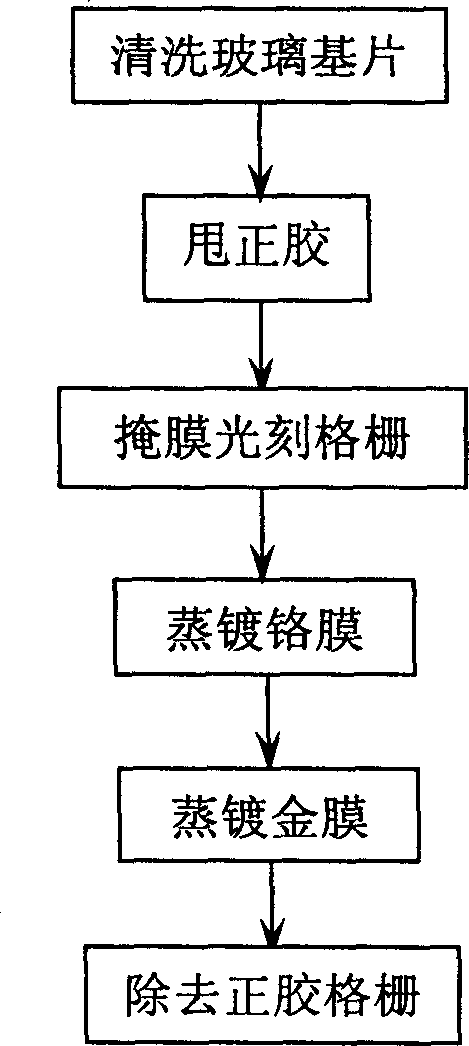

[0032] Such as figure 2 As shown, the present invention includes an optical glass substrate 5 , a chrome film microarray 6 , a bare gold film microarray 7 , a coupling layer 8 and a receptor 9 fixed together from bottom to top. The optical glass substrate 5 is an optical glass material with a refractive index of 1.5-1.8, its thickness is 0.8-1.2mm, and its size is 0.8×0.8-1.2×1.2mm 2 square piece or Φ0.4-0.6mm disc, smooth on both sides; the chrome film microarray 6 is vapor-deposited or sputtered on one side of the optical glass substrate 5, and the thickness of the chrome film is 2-5nm; the bare gold film The microarray 7 is evaporated or sputtered on the surface of the chromium film microarray 6, the thickness of the bare gold film is 30-50nm, and the number of units of the bare gold film micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com