Copolyimide gas separation membranes

A technology of gas separation membrane and polyimide, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems such as the tolerance of hydrocarbon solvents that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

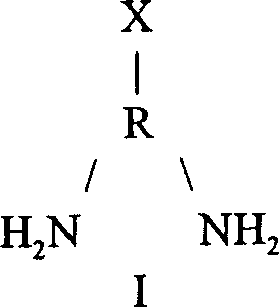

Method used

Image

Examples

Embodiment Construction

[0033] The invention is described below by way of examples of some representative embodiments thereof, in which all parts, ratios and percentages are by weight unless otherwise indicated. All weights and measurements not originally obtained in SI units have been converted to SI units.

[0034] A 250 mL three necked round bottom flask equipped with a mechanical stirrer, nitrogen inlet and Dean-Stark trap was flame dried under nitrogen atmosphere and allowed to cool to ambient temperature. The diamine mixtures shown in Table I (0.025 moles total) were all dissolved in about 80-90 mL of NMP. The aromatic dianhydride or mixture of dianhydrides in Table I (0.025 mole) was then added along with an additional 10-20 mL of NMP. The solution was stirred at room temperature for 2 hours. Then add about 30mL of o-dichlorobenzene (ODCB) or toluene, heat the solution and keep it at 150-180°C for 5-25 hours to azeotropically remove water. The polymer was then precipitated in water or metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com