Fuel-saving system for engine

An engine and power technology, applied in charging systems, engine components, machines/engines, etc., can solve problems such as increased fuel consumption, environmental pollution, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

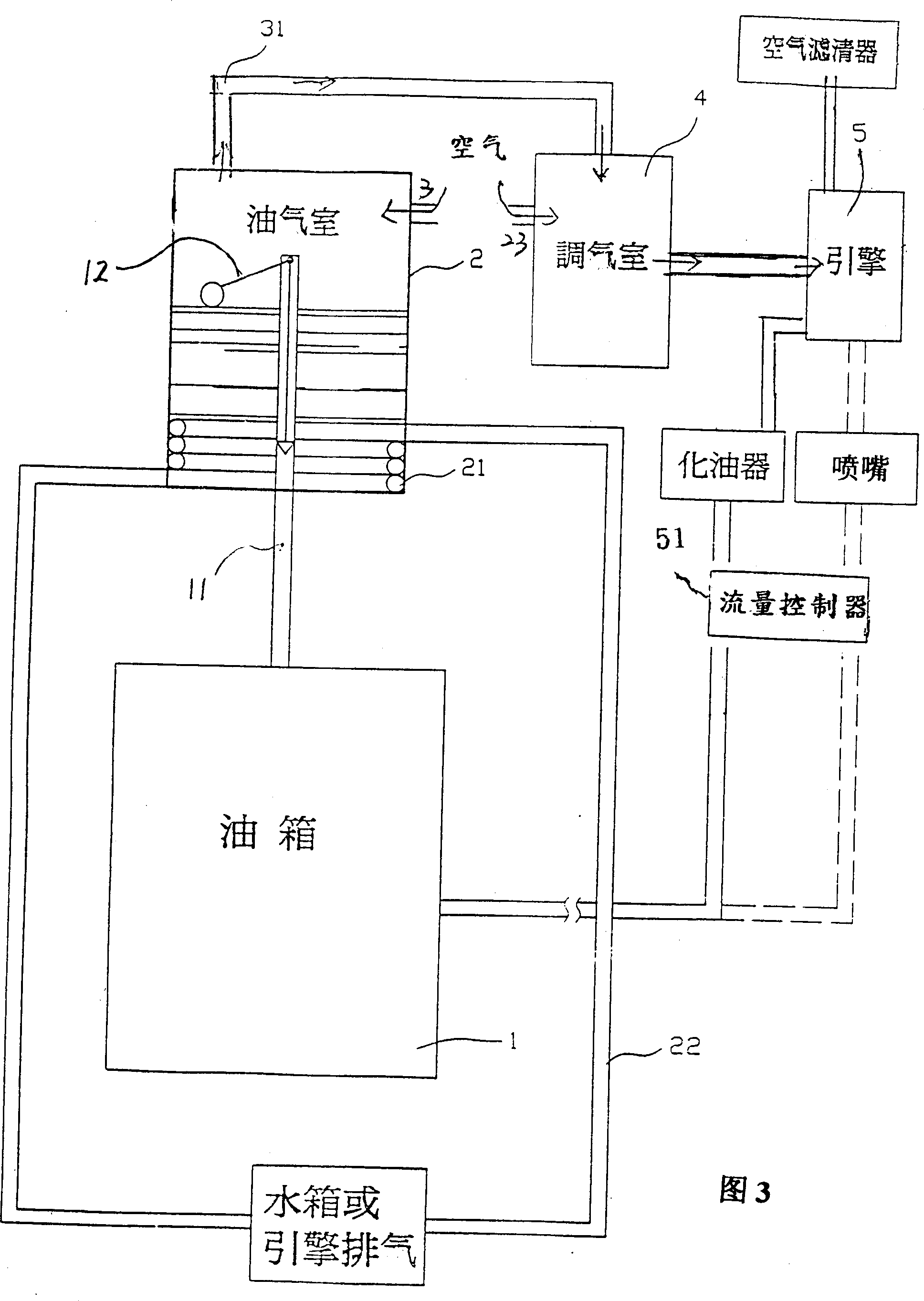

[0018] Please refer to Fig. 3, the fuel-saving system of the present invention is mainly to connect the fuel tank 1 with a fuel-gas chamber 2 through a pipeline 11 on the basis of the original fuel supply line, so that the fuel in the fuel tank 1 can be delivered to the fuel-gas chamber 2 The inner lower side of the oil-gas chamber 2 is provided with a heating pipeline 21, and the two ends of the heating pipeline 21 extend out of the oil-gas chamber 2, and are connected with the tank or engine exhaust to form a circulation loop 22, so that the high-temperature water in the water tank or The heat energy of the exhaust gas emitted by the engine flows into the heating pipeline 21 in the oil and gas chamber 2 to achieve the function of heating the inside of the oil and gas chamber 2, so that the oil and gas chamber is maintained at 60-70 degrees Celsius. At the same time, a switch is set in the pipeline 11 Valve 12, in order to control the amount of fuel oil entering the oil-gas ch...

Embodiment 2

[0020] Please refer to Fig. 4, when gasoline fuel is used, due to the high volatility of gasoline, it will volatilize quickly after heating, which will cause waste, and diesel gas can be used instead. Therefore, an independent auxiliary fuel tank 6 must be set in addition to provide oil and gas The fuel oil in chamber 2, like this, after heating, just can form the more stable oil gas of high volatilization. It is transported to the air chamber 4 by the negative pressure suction of the engine, and enters the engine 5 after desalination. At the same time, the supply of the crude oil tank is reduced to 30% to 40% of the gasoline mixed with the input engine to detonate to provide power.

Embodiment 3

[0022] For injection engines, the fuel supply is controlled by the computer, and gasoline is a highly volatile fuel, so the fuel tank 1 can be used instead of the oil and gas chamber 2 without heating the pipeline 21. The negative pressure suction of the engine is controlled by the oil and gas chamber 2. The oil vapor is transported to the gas regulating chamber 4. After desalination, it enters the engine, and then the original vehicle provides the original fuel supply, which is input into the engine to mix and provide power, which can also achieve the purpose of saving fuel and reducing air pollution.

[0023] See experimental data:

[0024] speed

[0025] speed

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com