System and method for removing organic oxide from waste water

A technology for organic matter and wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

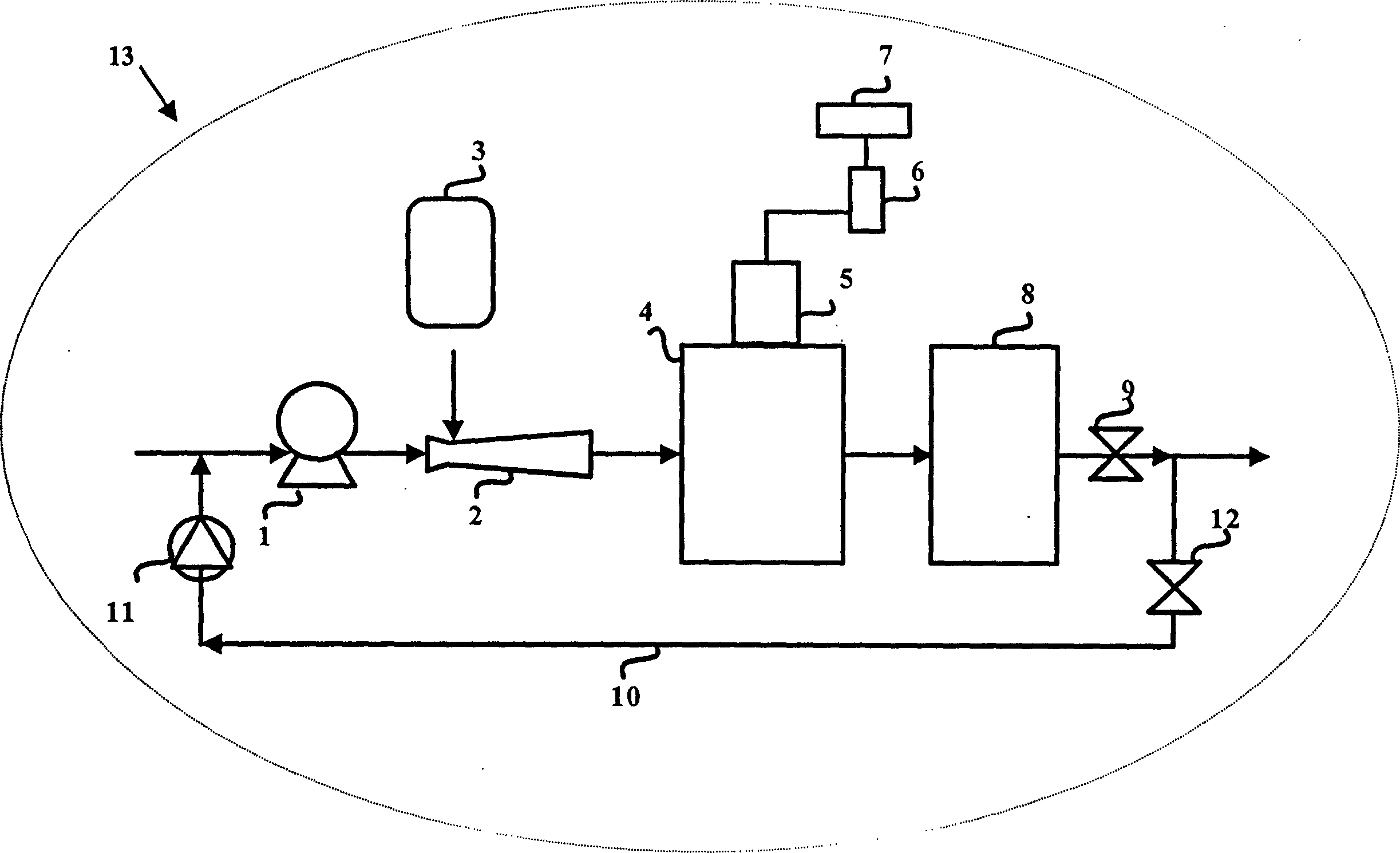

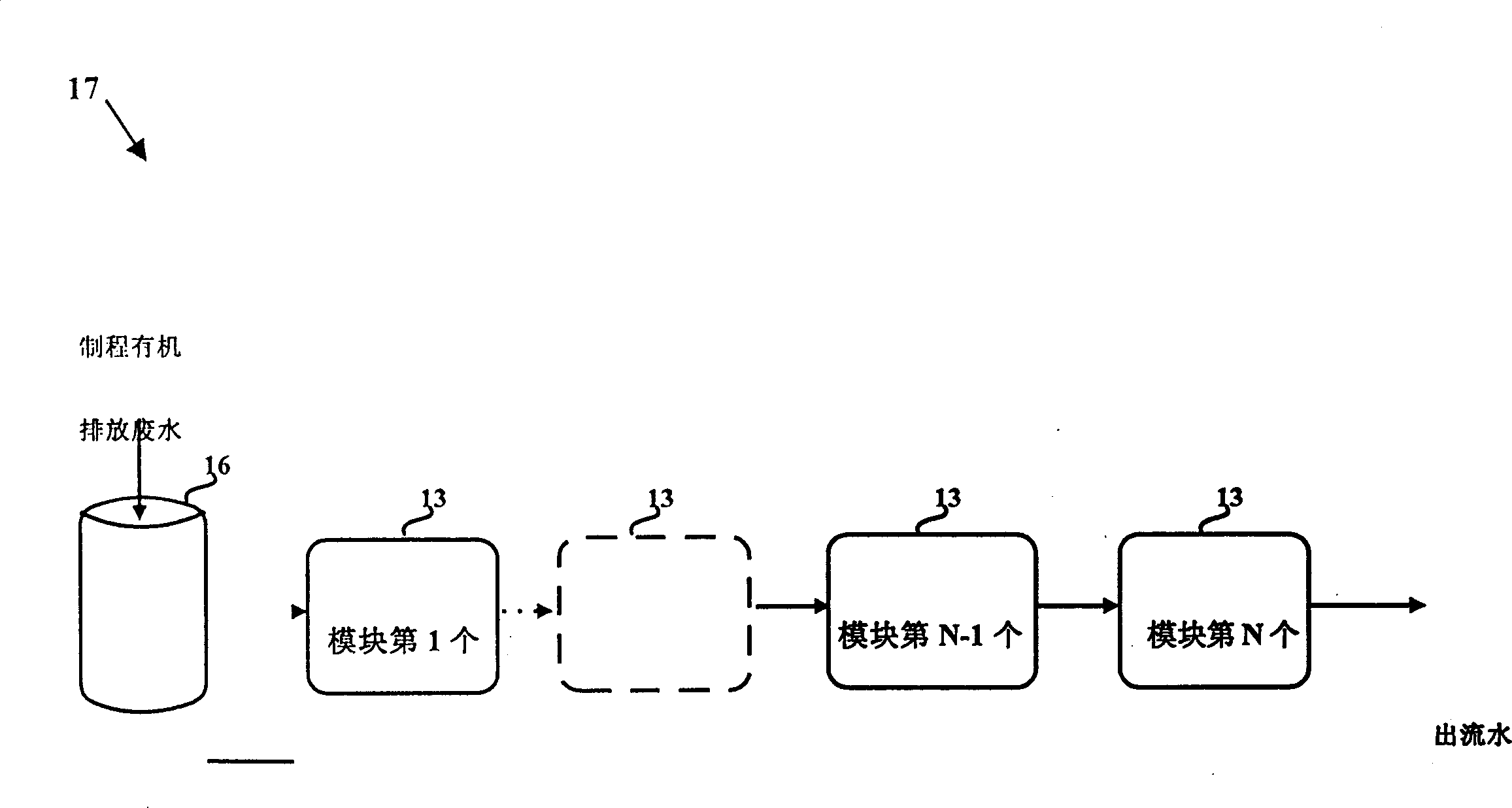

[0039] use as figure 1 The module shown in the figure was used to carry out the oxidation removal experiment of organic matter on a wastewater containing IPA with a TOC value of about 18600 ppb.

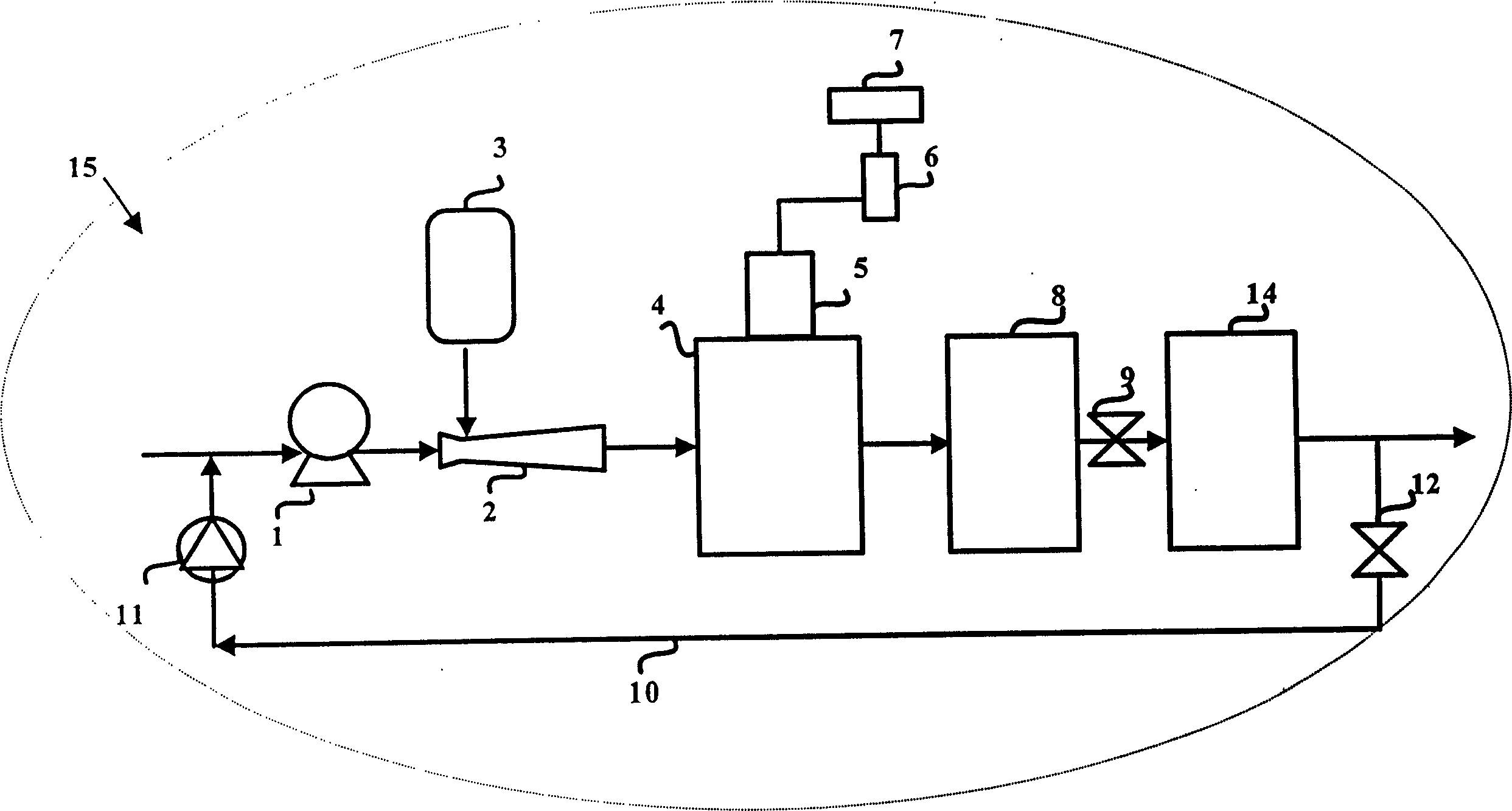

[0040] The ozone concentration of the ozone / wastewater mixture in the ozone inhaler is maintained at 20ppm, and the pressure difference is 2.8kg / cm 2 . The residence time in the ozone dissolving tank was 41 seconds. The flow ratio of backflow water to outflow water is controlled at 4:1. The TOC value of the effluent was reduced to 12250ppb, and the removal rate was 34%. Repeating the above-mentioned experimental steps, the TOC value dropped from 12250ppb to 7840ppb, and the removal rate was 36%. Repeating the above experimental steps, the TOC value dropped from 7840ppb to 4468ppb, and the removal rate was 43%. It can be seen that when the above steps are implemented repeatedly, the wastewater can be reduced to the desired concentration range; and the series connection of UV / ozon...

Embodiment 2

[0042] The experimental procedure of Example 1 was repeated, but the influent water was changed to a waste water containing NMP with a TOC value of about 10053 ppb, the effluent TOC value was about 6700 ppb, and the removal rate was 33%. Repeating the above experimental steps, the TOC value dropped from 6700ppb to about 3820ppb, and the removal rate was 43%. It can be seen that when the above steps are implemented repeatedly, the wastewater can be reduced to the desired concentration range; and the series connection of UV / ozone oxidation removal modules can be continuous or discontinuous, that is, insert other non-UV / ozone oxidation removal modules between one module and the next module. Other purification components of the ozone oxidation removal module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com