AC generator for vehicle

A technology for alternators and vehicles, applied in the direction of synchronous generators, electric components, electrical components, etc., which can solve problems such as large wind noise, reduced output power, and poor magnetic circuit characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

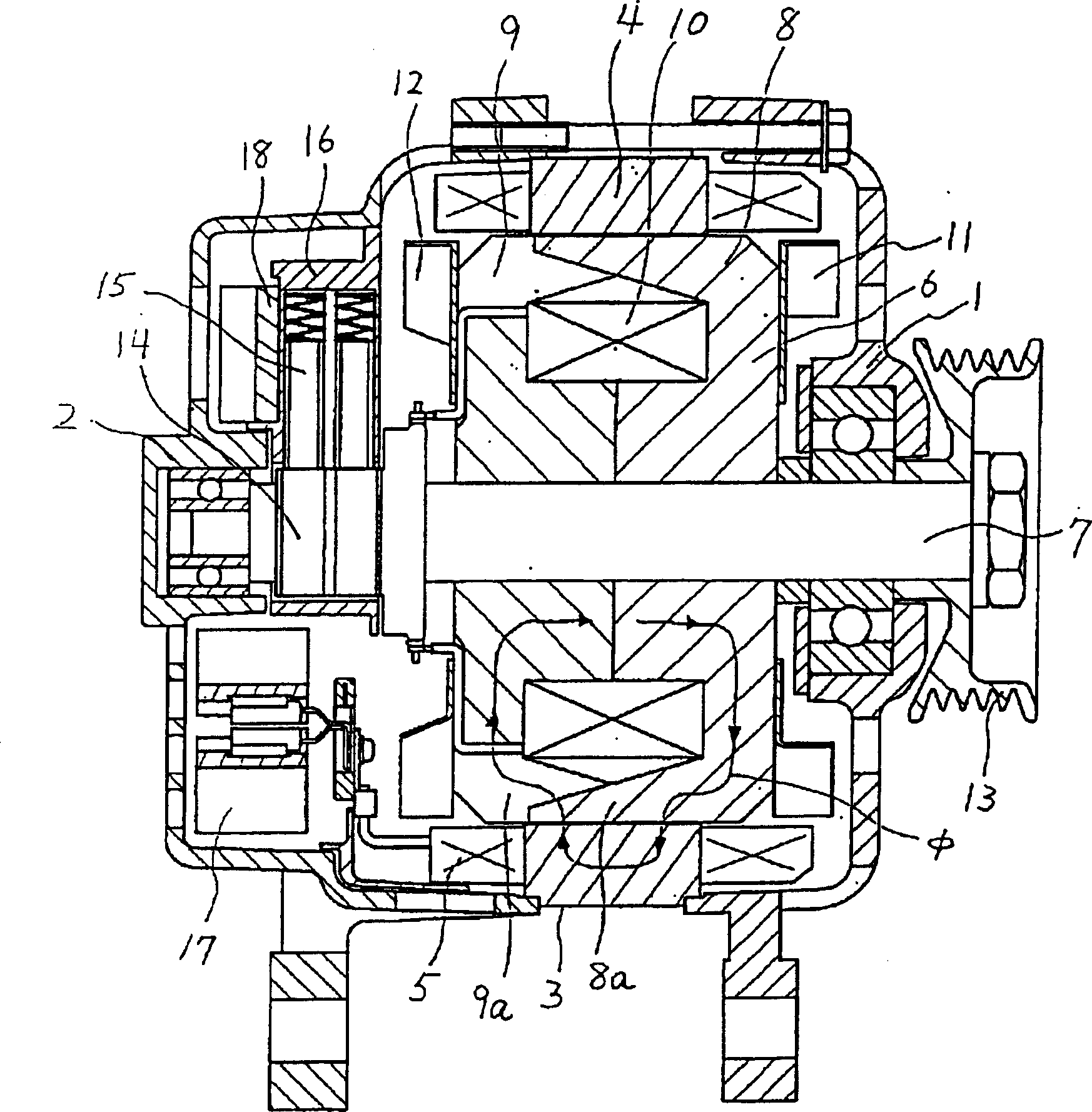

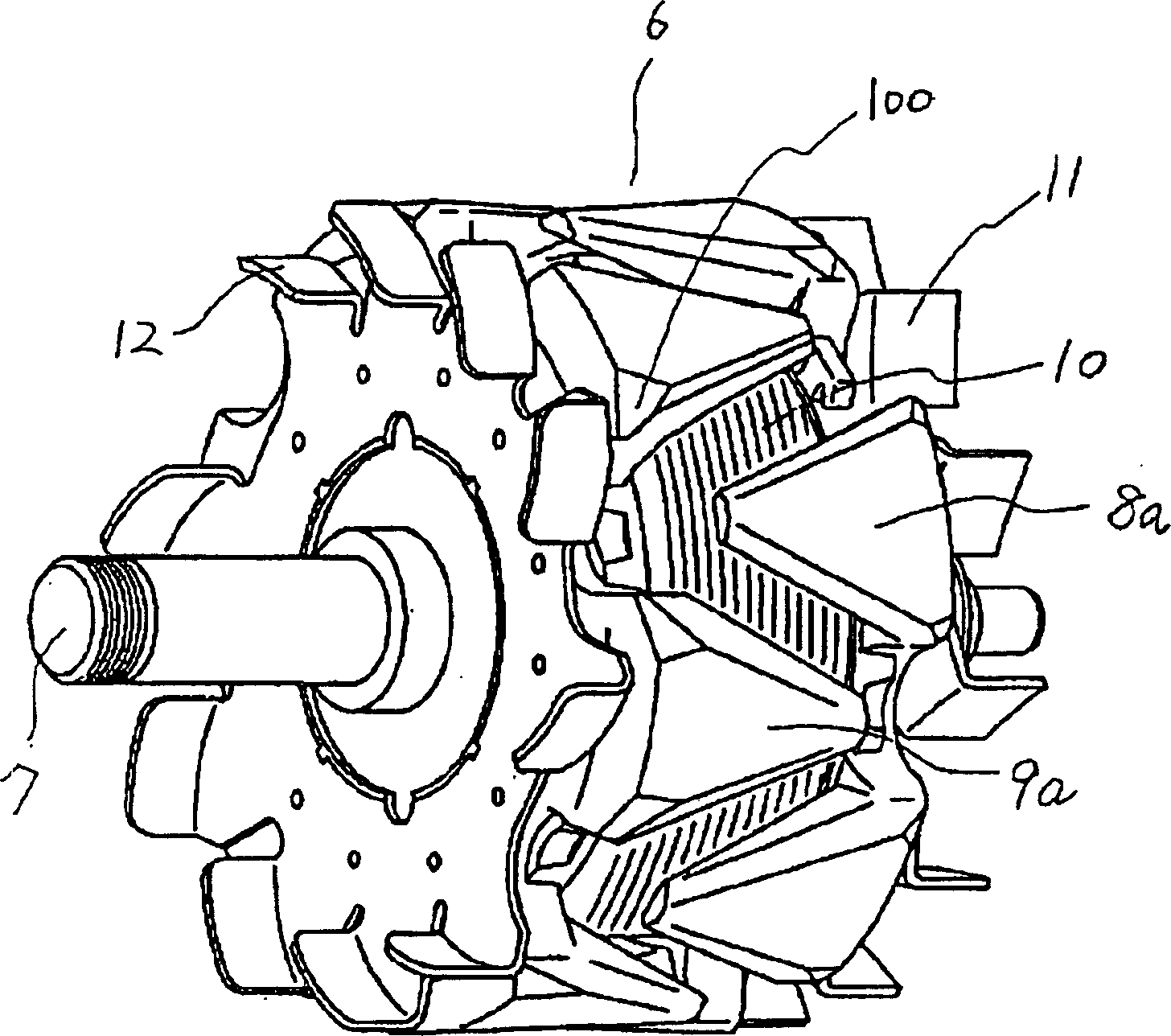

[0051] figure 1 is a cross-sectional view of the vehicle alternator according to Embodiment 1 of the present invention, figure 2 yes figure 1Oblique view of the middle rotor. In the figure, 1 is the front bracket, 2 is the rear bracket, and 3 is the stator held by the front bracket 1 and the rear bracket 2, which consists of the stator core 4 and the winding wire inserted into the slot of the stator core 4. Winding 5 constitutes.

[0052] 6 is the rotor tightly fixed on both ends of the rotating shaft 7 supported by the front bracket 1 and the rear bracket 2, consisting of the first rotor core 8; the second rotor core 9; the excitation coil wound between the two rotor cores 8 and 9 Coil 10; the fan 11,12 that is arranged on the back side of two rotor cores; the belt pulley 13 that is arranged on the outside of the front bracket 1 side of the rotating shaft 7; Ring 14 constitutes.

[0053] 15 is a brush that supplies current to the slip ring 14, 16 is a brush holder for...

Embodiment approach 2

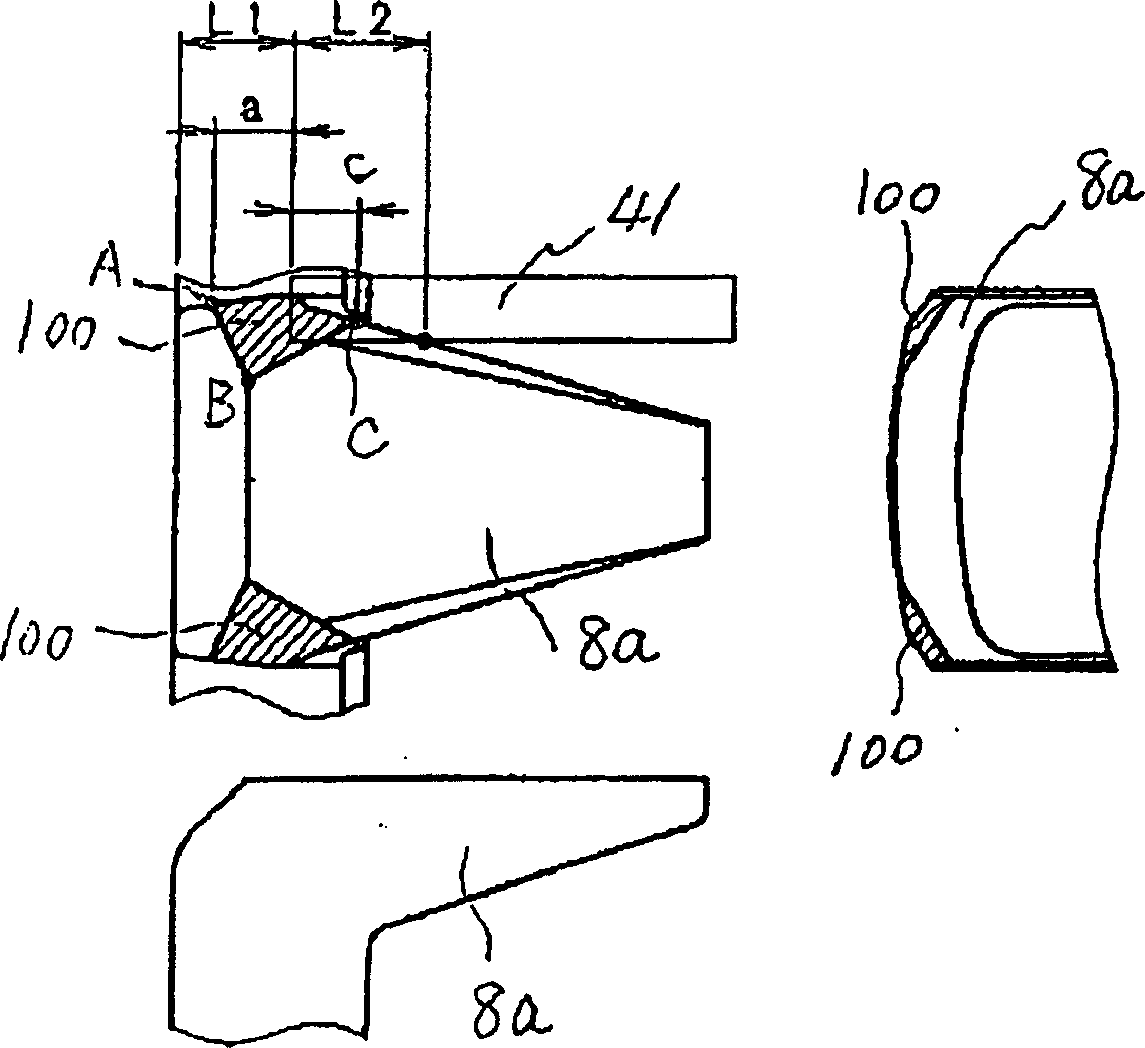

[0063] In this embodiment, the position of the point C on the twisted inclined portion of the pole piece 8a according to the first embodiment will be described in detail. This point C is preferably at the position where the tops of the T-shaped bars 41 of the stator core 4 overlap radially, Figure 5 It is the pole piece 8a leakage magnetic flux diagram of the rotor 6. As shown in the figure, there is a magnetic leakage flux φ leaking from the pole piece 8a to the pole piece 9a through the T-bar 41 at the radial overlap of the top end of the pole piece 8a and the T-shaped bar 41 . This is because the pole piece 8a and the top end of the T-shaped bar 41 face the cause with a small radial gap. However, in the present embodiment, the top end of the T-shaped bar 41 is overlapped on the chamfered portion 100 of the pole piece 8a. Larger, the leakage flux can be reduced.

[0064] In more detail, in image 3 Among them, the overlapping amount C is preferably equal to or less than...

Embodiment approach 3

[0066] Figure 7 It is an enlarged view of the pole piece 8a of the rotor 6 of the vehicle alternator according to Embodiment 3 of the present invention. In this embodiment, as shown in the figure, the distance between two points B on the tapered starting line of the base shoulders of the two chamfers 100 formed by the pole piece 8a is denoted as S, and the distance S should be formed It is approximately half or less of the circumferential width H of the pole piece 8a.

[0067] Figure 8 is the relationship between distance S and electromagnetic noise. In the figure, the vertical axis represents the sound level (sound pressure level) (dB) of the generator electromagnetic noise. The horizontal axis represents the distance S. As shown in the figure, it is clear that the distance S is less than half of the circumferential width H of the pole piece 8a, and the electromagnetic noise is small, below 78dB, but when the distance S is more than half of the circumferential width H o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com