X-ray tube with ring anode and its application

A technology of X-ray tube and annular anode, which is applied in the field of X-ray tubes and can solve problems such as expensive structure, large size and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

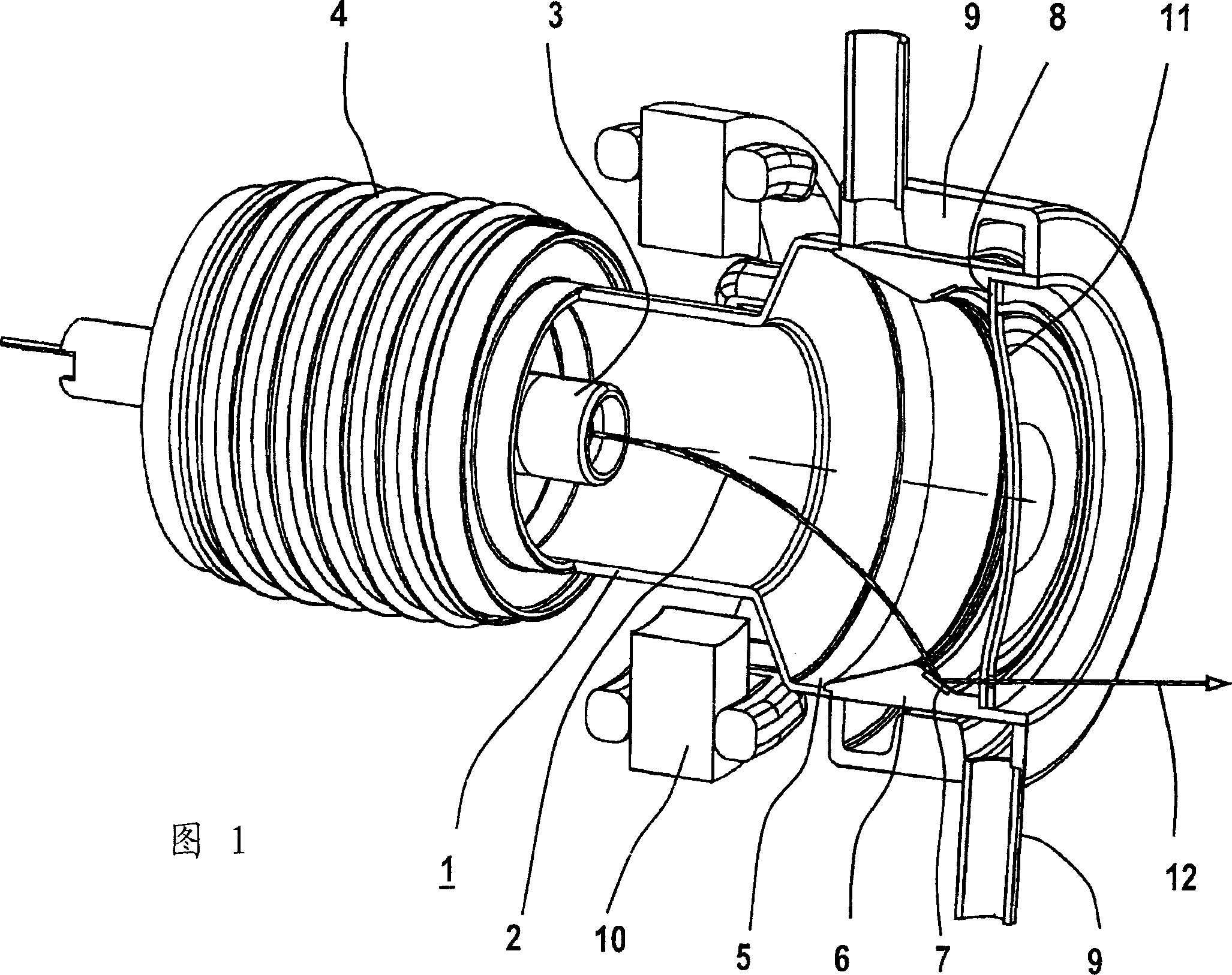

[0026] FIG. 1 shows the x-ray tube according to the invention with a vacuum housing 1 in which a cathode 3 with a circular emitter for generating an electron beam 2 is located.

[0027] The cathode 3 is connected to an annular anode 6 via an insulator 4 and a widened tube section 5 . The inwardly directed surface of the ring-shaped anode 6 has an essentially triangular cross-section consisting of a long side and a short side, the long side facing the cathode 3 . An impact surface 7 is provided for the electron beam 2 on the short side.

[0028] A radiation exit window 8 through which x-rays pass is arranged in front of the annular anode 6 and forms the front cover of the x-ray tube. An anode cooling system 9 is arranged around the ring-shaped anode 6 , which has an inlet and an outlet and channels for the flow of cooling fluid and is thermally conductive, in particular in the region of the impingement surface 7 , with the The ring anode 6 is connected. In the area of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com