Constant-temp. forging in the air for nickel-base super heat-resistant alloy

A superalloy, nickel-based technology, used in metal processing equipment and other directions, can solve problems such as increasing the complexity and cost of the forging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

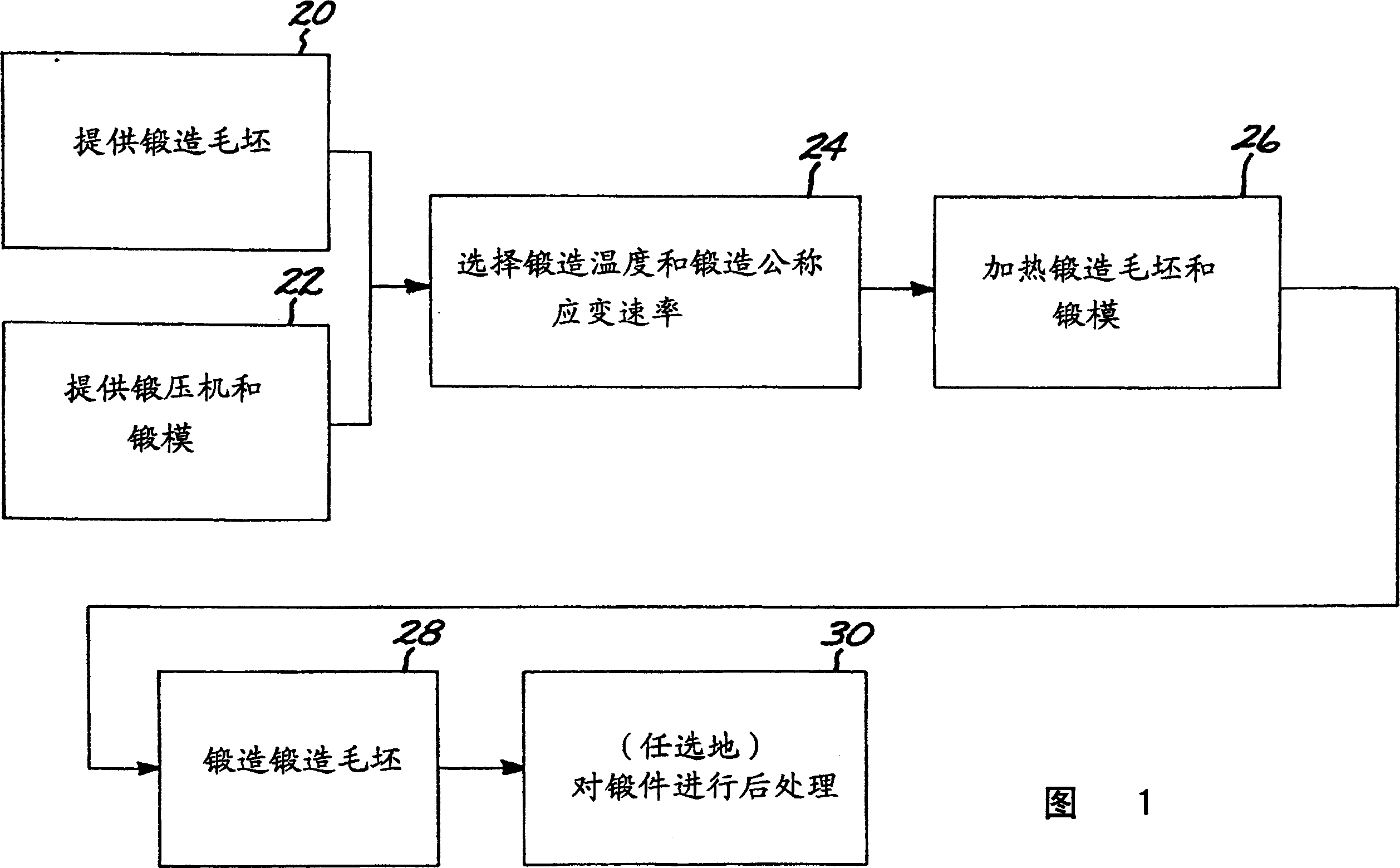

[0019] Figure 1 depicts a preferred method of practicing the invention. Step 20 is to provide a forging blank. This forging blank is prepared from a forged nickel-based superalloy. As used herein, an alloy is a nickel-based alloy when nickel is present in excess of other elements; and when strengthened by the deposition of gamma prime or other related phases, it further forms a nickel-based superalloy. Rene TM 88DT and ME3 are two nickel-based superheat-resistant alloys with special properties, Rene TM The nominal composition of 88DT is by weight: 13% cobalt, 16% chromium, 4% molybdenum, 3.7% titanium, 2.1% aluminum, 4% tungsten, 0.75% niobium, 0.015% boron, 0.03% Zirconium, 0.03% carbon, up to about 0.5% iron, the balance is nickel and a small amount of impurity elements; the nominal composition of alloy ME3 is by weight: about 20.6% cobalt, about 13.0% chromium, about 3.4% Aluminum, about 3.70% titanium, about 2.4% tantalum, about 0.90% niobium, about 2.10% tungsten, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com