Refinery furnace hot-pack plug-rod multi-box casting device system

A technology for refining furnaces and stopper rods, which is applied in casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems such as greater influence of electrical components, poor accuracy of electrical transmission control, and failure to conform to the normal production process, etc., to achieve Good economic value and social value, reasonable equipment design, and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

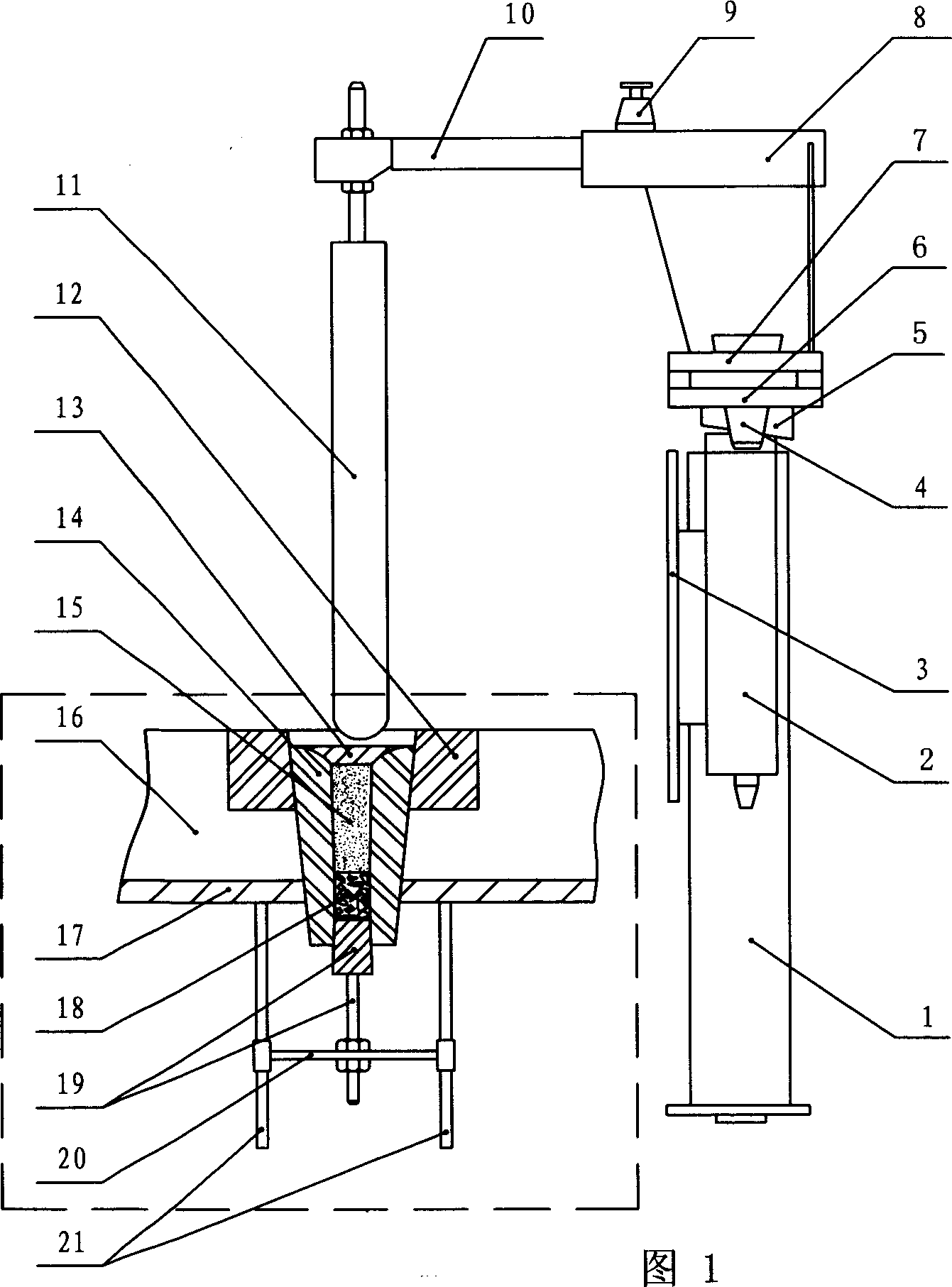

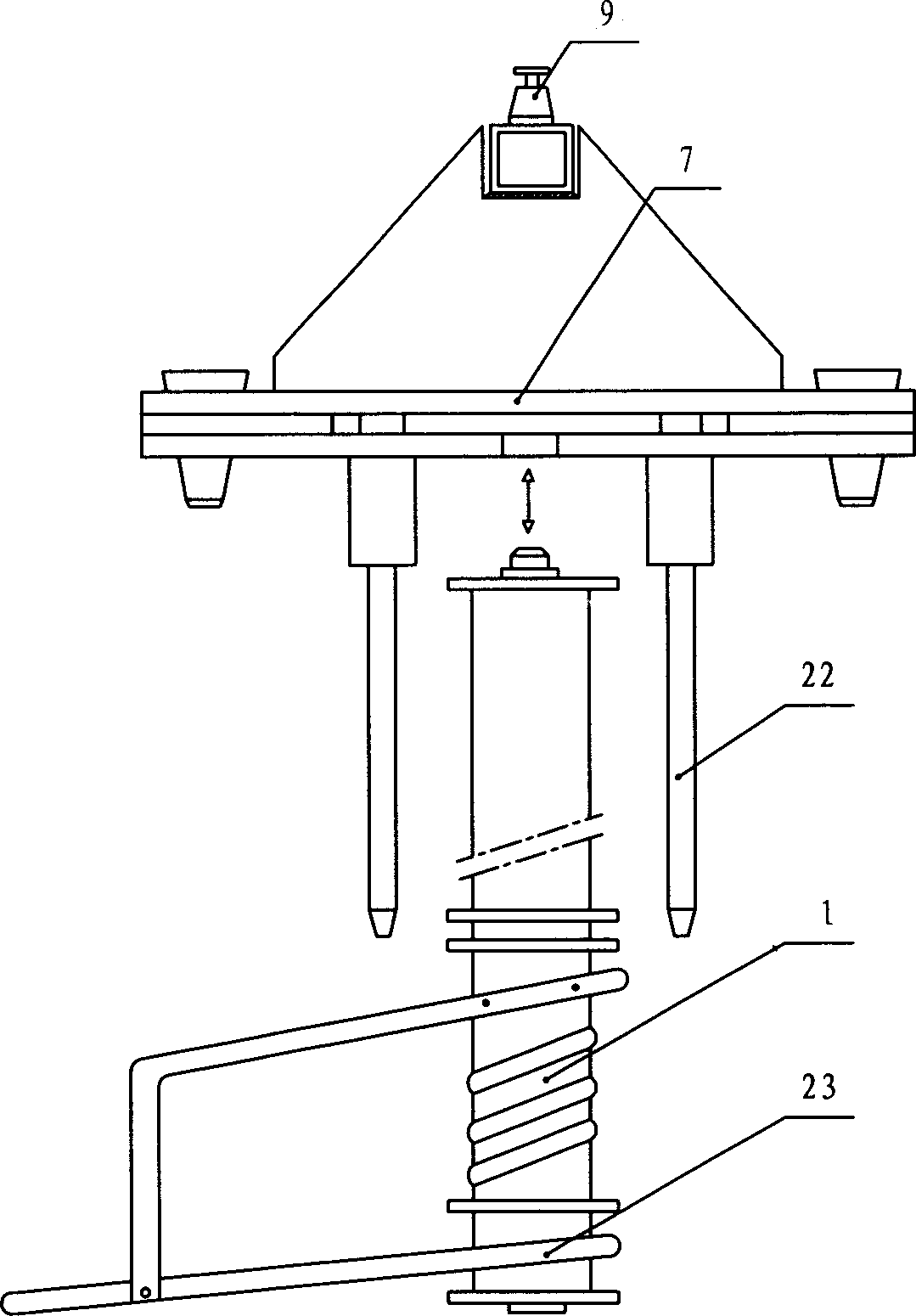

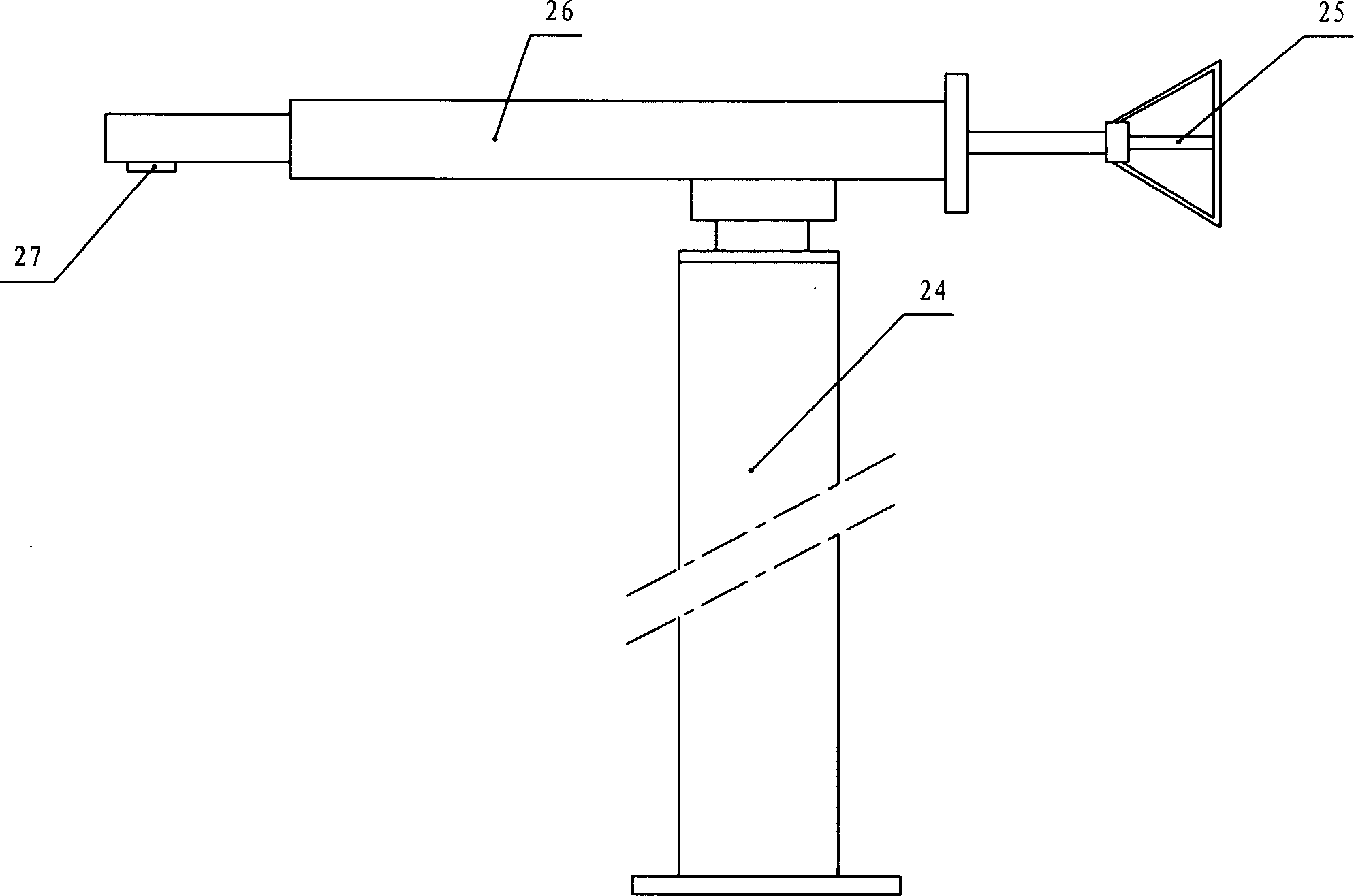

[0015] Figure 1, figure 2 , image 3 As shown, the lifting and lowering rod structure of the present invention includes a lifting mechanism 1, a guide sleeve 2, a fixed bottom plate part 3, an upper and lower connecting taper pin 4, a wedge iron 5, a connecting bottom plate 6, a stopper rod holder fixed support 7, and a stopper rod holder 8 , hoisting pin 9, telescopic arm of the gripper 10, plug rod 11, guide rod 22, pressure handle 23, lifting hydraulic cylinder 24, hand swivel 25, plug rod crane telescopic arm 26, socket 27 and other main parts, the sealing water port at the bottom of the refining furnace The structure includes (the part inside the dotted line frame in Figure 1): seat brick 12, cast iron cover plate 13, nozzle brick 14, drainage sand 15, refractory lining 16, refining furnace bottom 17, cast iron scrap 18, plug head 19, rotatable bracket 20 , bracket 21,

[0016] When in use, hoist the plug rod 11 into the refining furnace to align the relative position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com