Method and device for producing substantially endless find threads

A continuous, filamentary technology, applied in the direction of monocomponent cellulose rayon, melt spinning, stretch spinning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042]Through a screw extruder, 13% cellulose and 12% water in a 75% aqueous NMMO solution are supplied to a spinning device, which includes a spinneret with a hole and a circular Laval nozzle, the only The diameter of the spinneret hole is 0.5mm. The solutions are produced on an industrial scale and are directly pumped and dosed to the spinning unit. The temperature of the profiled fiber mass at the exit of the extruder was 94°C. A resistance heater with a power of 50W-300W is installed at the lower part of the conical nozzle head for heating. At a room temperature of about 22°C, the air elongates the filament long, and the measured pressure is adjusted to 0.05 bar - 3 bar above atmospheric pressure before accelerating inside the Laval nozzle. The outflow of profiled fiber mass from the nozzle orifice varies only slightly and is 1mm-2mm above the Laval nozzle constriction plane, where further adjustments are made just in this plane or even below it, ie 1mm-2mm in the downst...

example 2

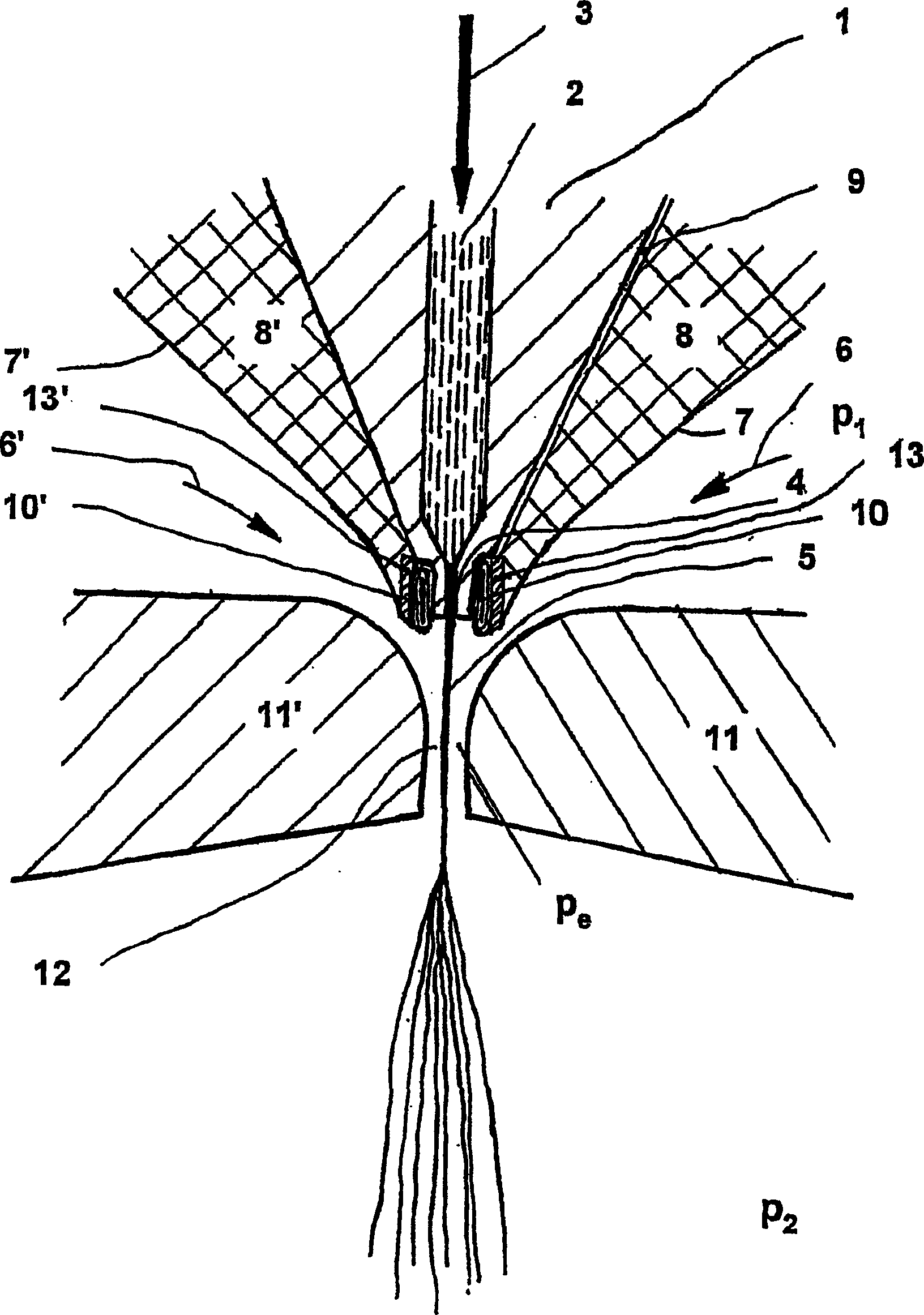

[0046] in such as figure 1 In the apparatus shown, a solution containing 8% cellulose in 78% NMMO and the balance 14% water was spun from a spinneret hole with a diameter of 0.6 mm. The temperature of the solution was 115°C at the exit of the extruder and 114°C in the solution distribution chamber before a total of 20 orifices. The heating power of the heating devices on both sides of the nozzle head is 450W. The throughput of each spinneret hole is 3.6 g / min.

[0047] Depending on the pressure of the unheated air, the following substantially continuous profiled fiber diameters were obtained.

[0048] Preface

No

P1

mbar

d 50

μm

d min

μm

d max

μm

cv

%

u Le

m / s

u F50

m / s

5

160

8.5

2.8

21.1

59

156

67

7

200

8.0

3.7

14.7

39

173

78

9

25...

example 3

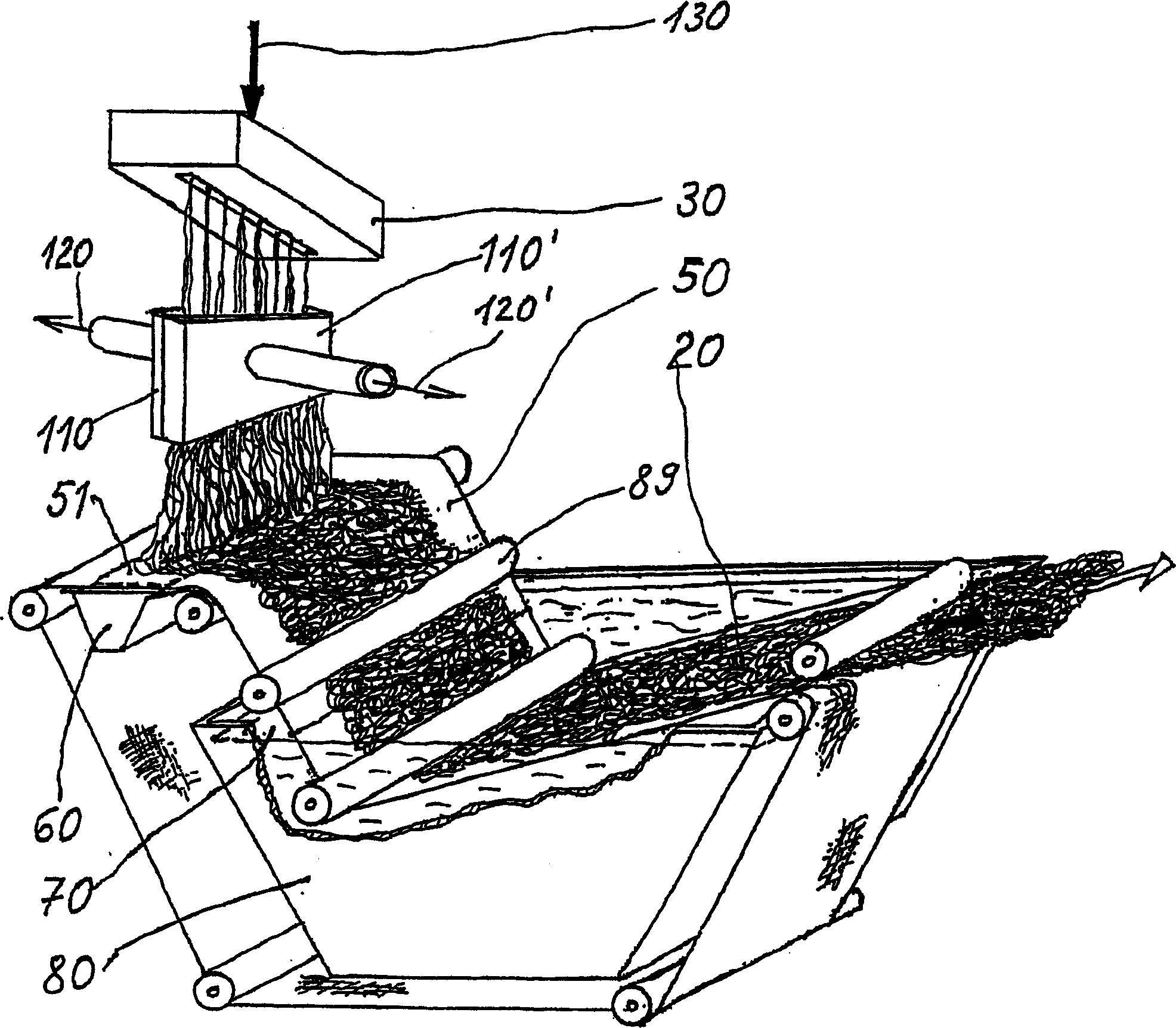

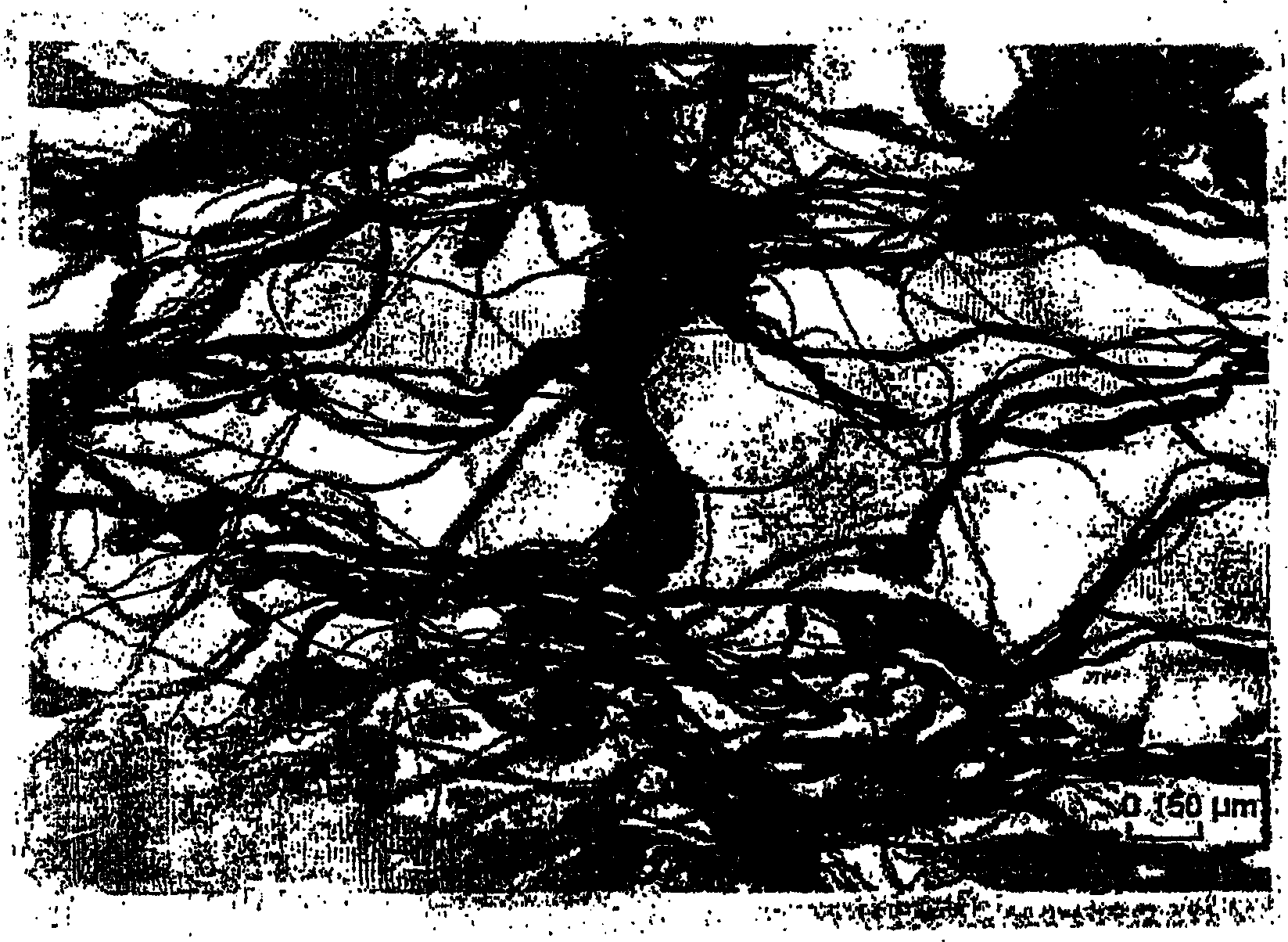

[0055] in similar to figure 1 In a spinning device of the shown device, from a slot 0.9 mm wide and 20 mm long, a polypropylene melt at 355° C. is spun from a spinneret terminated in a diaphragm-like bottom. Air was used as the stretching gas for the film. At a flow rate of 11.5 g / min and an air pressure of 250 mbar at room temperature 20° C., filaments with a deviation s=1.9 μm and an average diameter of 5.2 μm occur corresponding to a coefficient of variation CV=37%. Furthermore, the location of thick knots in nonwoven fabrics was not measured simultaneously. image 3 shows the resulting nonwoven fabric, which shows a micrograph of PP split filaments according to Example 2. exist Figure 4 For comparison, polypropylene split filaments are shown spun from otherwise identical circular spinneret holes with a diameter of 1 mm and a throughput per hole of 3.6 g / min. Figure 4 The filaments in have an average diameter of 8.6 mm with a coefficient of variation of 48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com