Vacuum casting appts.

A vacuum and vacuum technology, applied in foundry workshops, foundry equipment, manufacturing tools, etc., can solve the problems of rust stains, low device operation efficiency, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

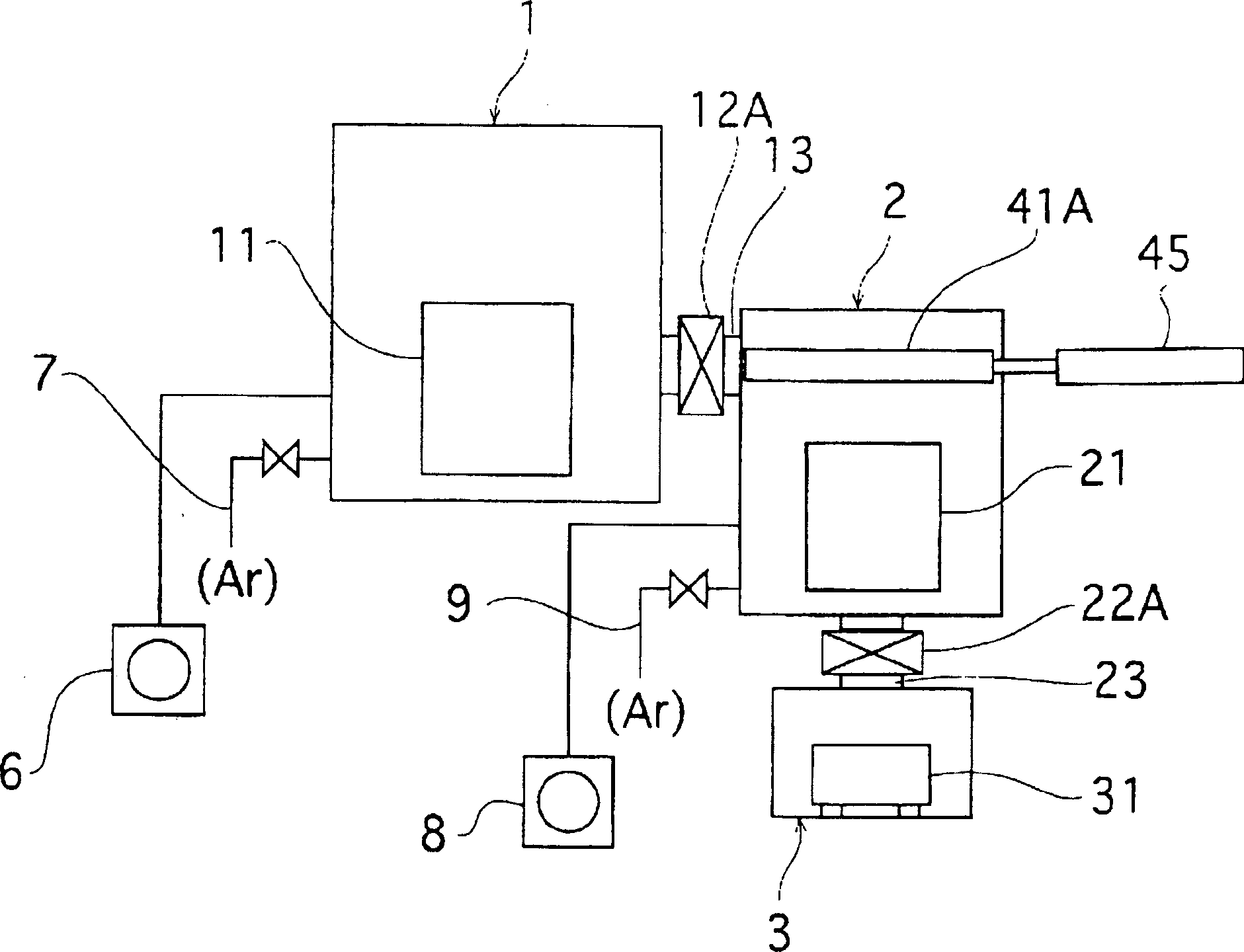

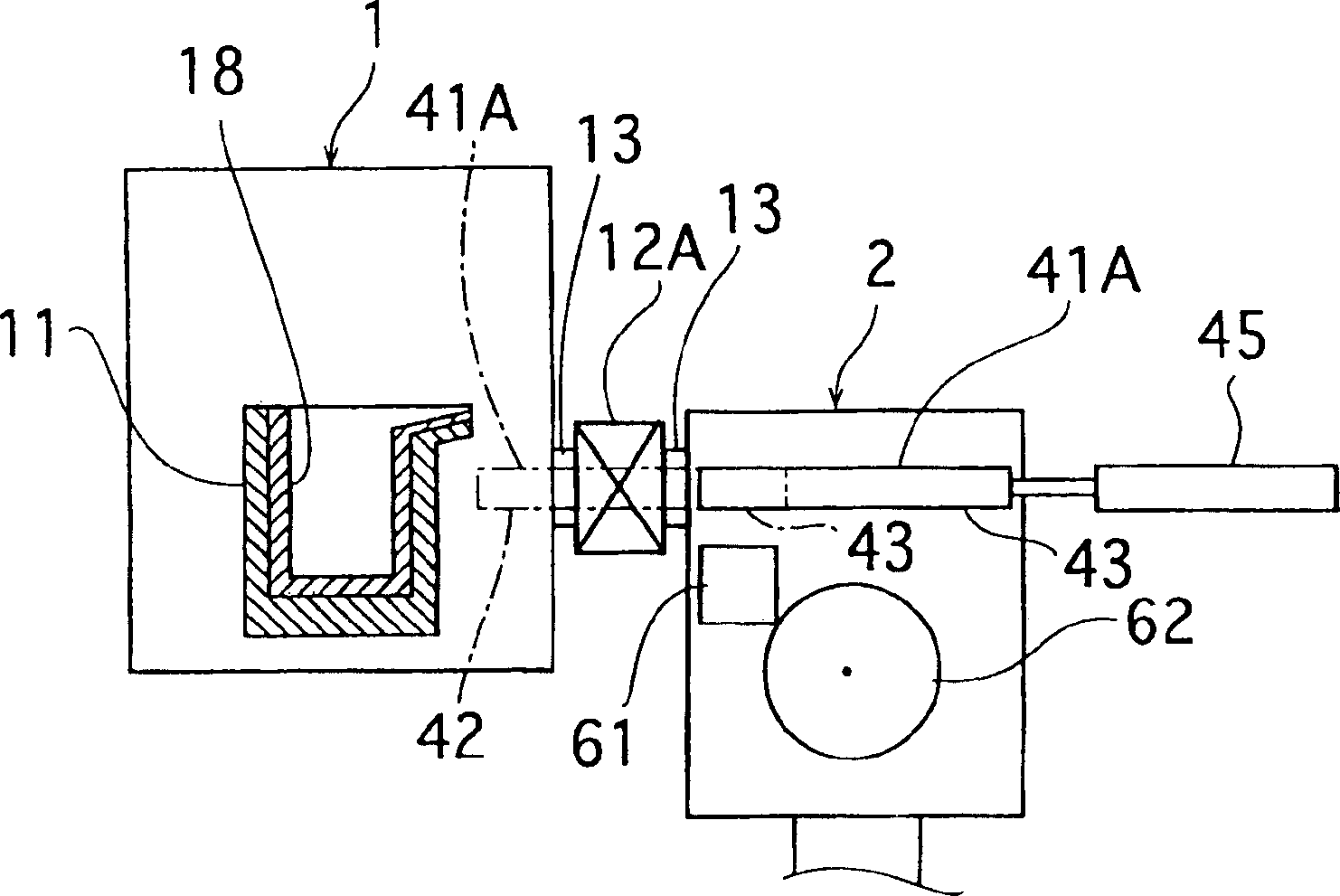

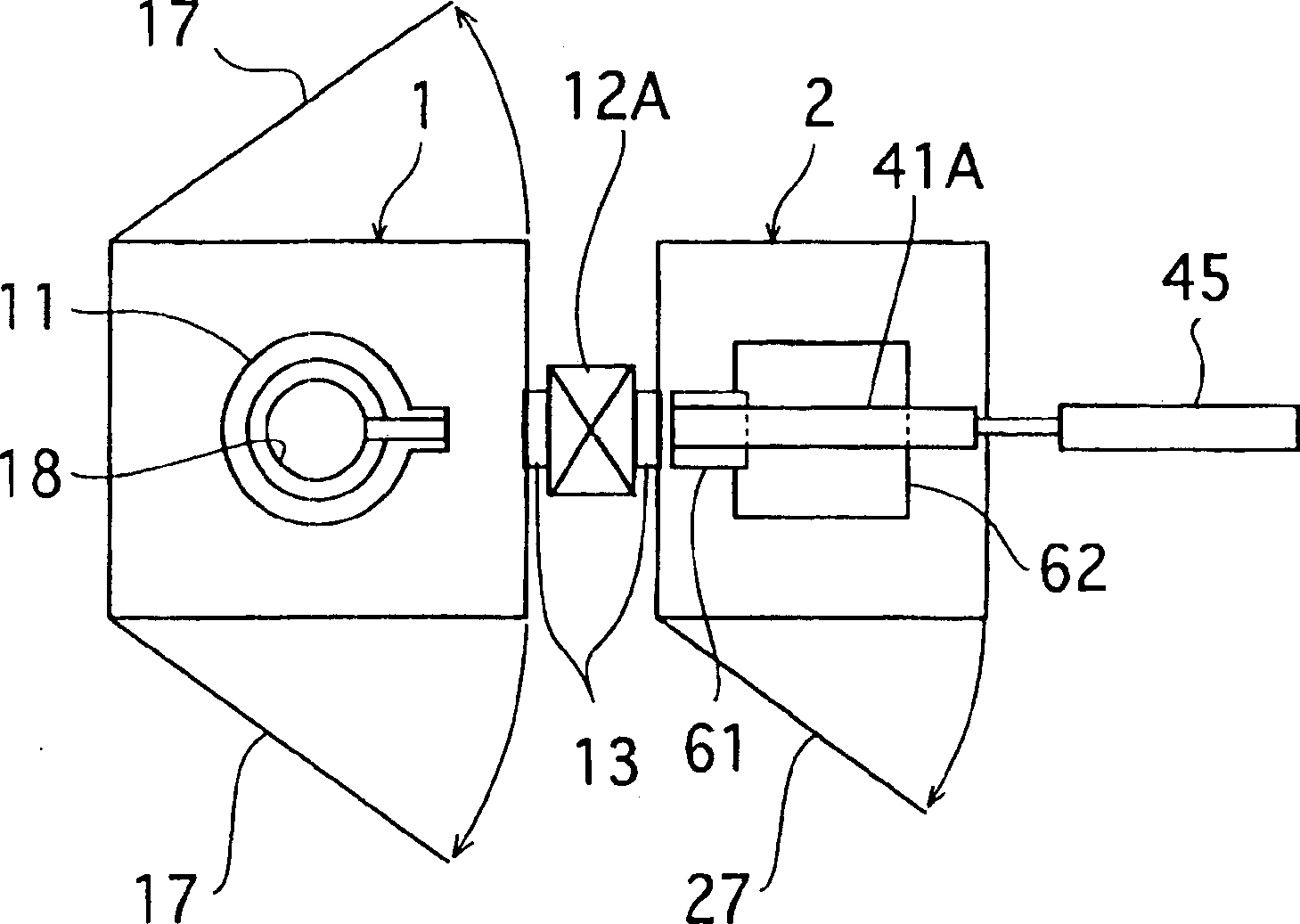

[0059] As described above, the vacuum melting and casting apparatus of the present invention includes a melting furnace that melts an alloy containing rare earth elements under vacuum or an inert gas atmosphere, and a casting apparatus that cools and casts the molten metal of the alloy. The melting chamber of the furnace and the casting chamber with the casting device are formed, and the melting chamber and the casting chamber are vacuum-sealed through the first partition mechanism or the first sealing mechanism provided with the first partition mechanism regardless of the vacuum degree of the two. The vacuum melting and casting device may also include a melting furnace for melting alloys containing rare earth elements under vacuum or an inert gas atmosphere, a casting device for cooling and casting molten metal of alloys, and a recovery of castings formed by receiving and outputting The vacuum melting and casting device is composed of a melting chamber with a melting furnace, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com