Aluminum electrolytic condenser

A technology of aluminum electrolytic capacitors and capacitor cores, applied in electrolytic capacitors, solid electrolytic capacitors, capacitors, etc., can solve the problems of current capacity heating, inability to flow current, and heat generation, and achieve strong noise absorption, less heat generation, and reduced heat generation. The effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the accompanying drawings.

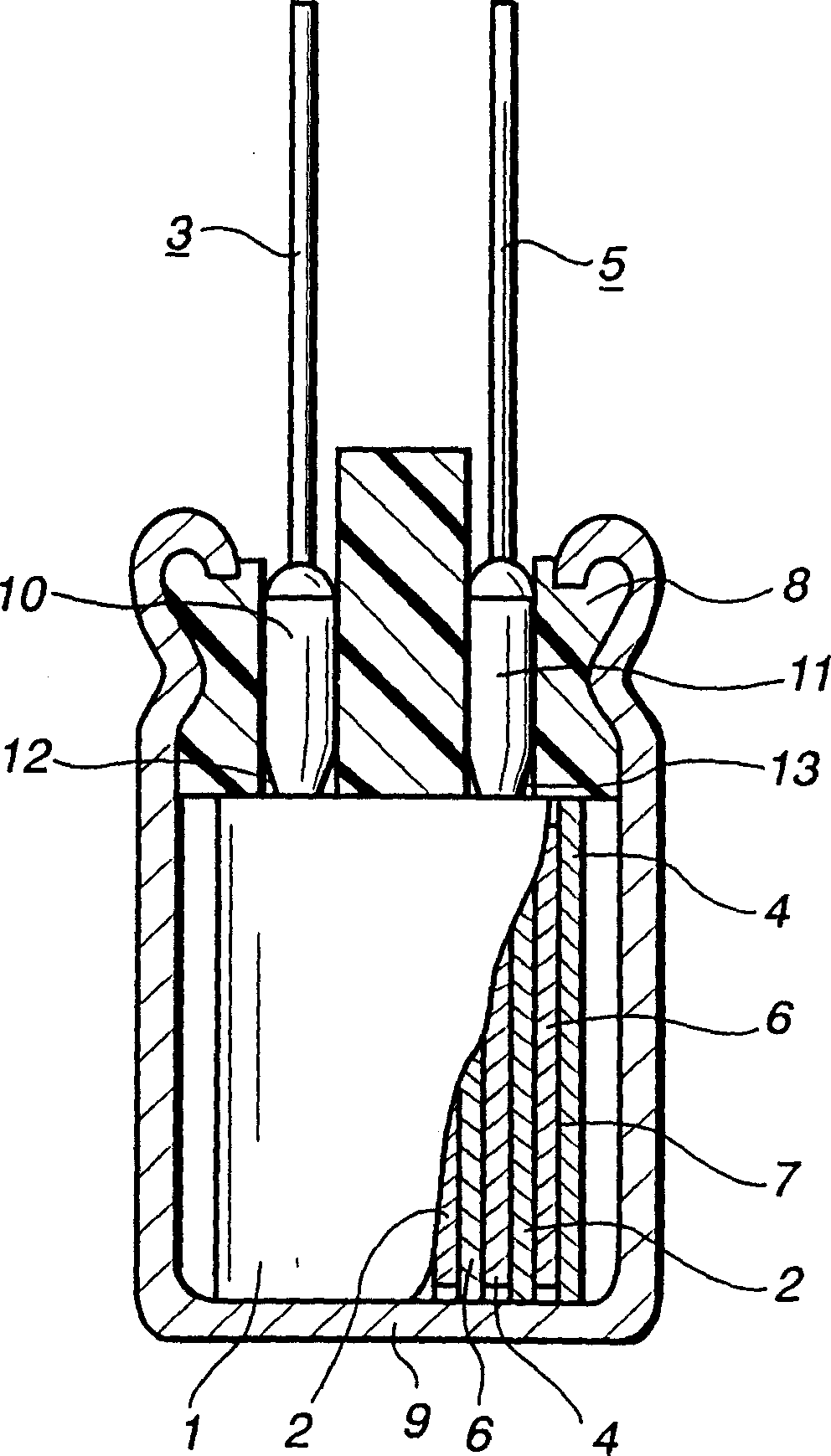

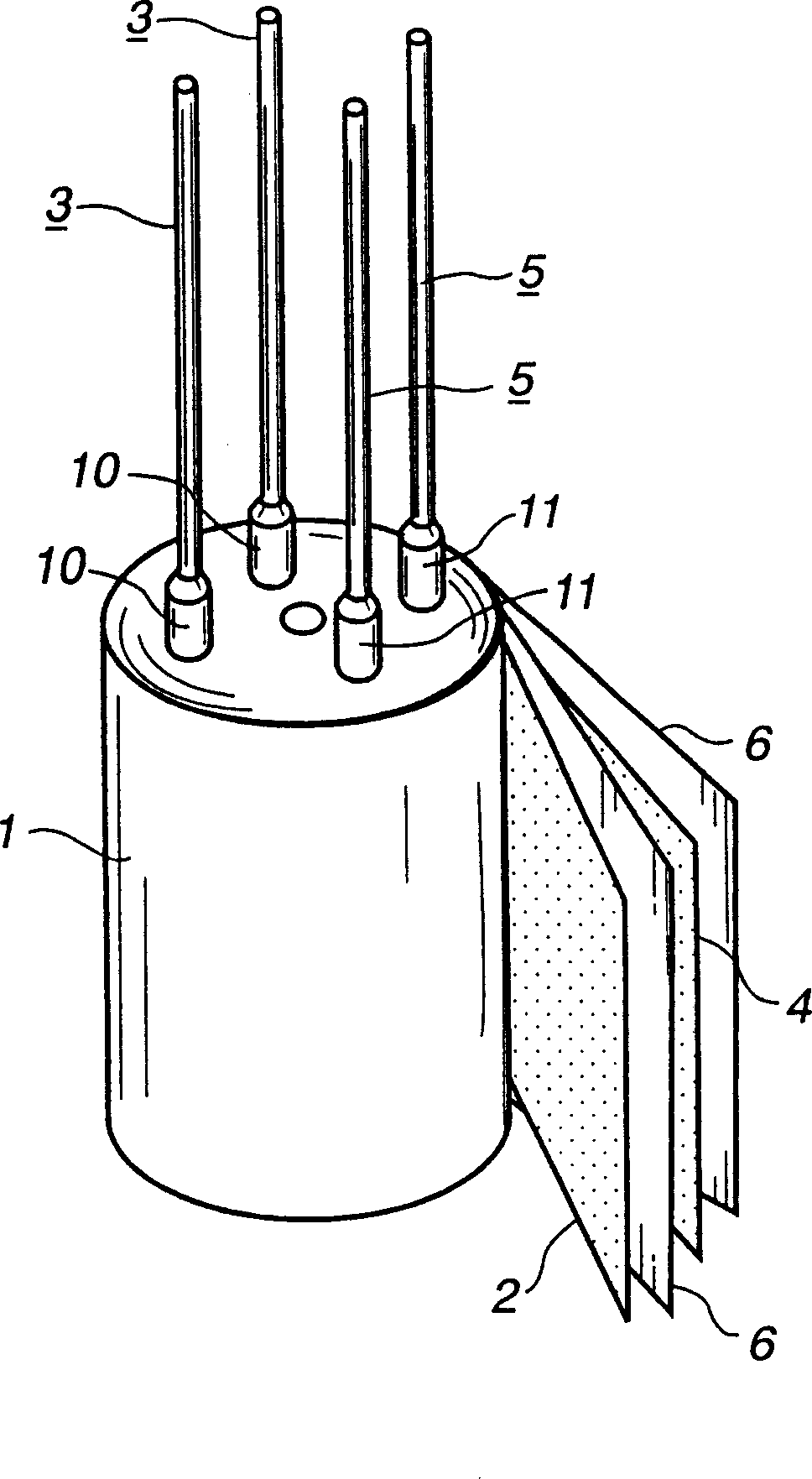

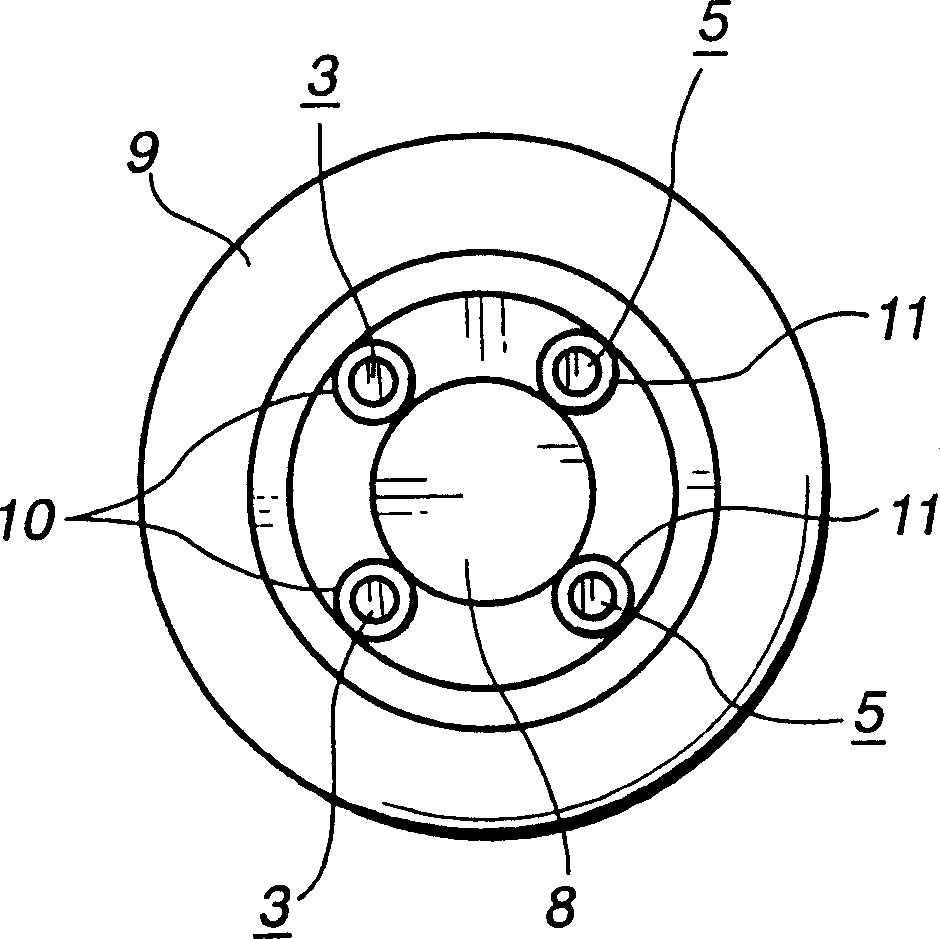

[0048] exist figure 1 , figure 2 and image 3 Among them, the wound solid electrolytic capacitor is composed of a capacitor core 1 , a solid electrolyte layer 7 , a sealing body rubber 8 and a case 9 .

[0049] The capacitor core body 1 formed with the solid electrolyte layer 7 and the sealing body rubber 8 are put into the casing 9 for sealing, and together with the casing 9, the sealing body rubber 8 is laterally shrunk and crimped, and then sealed to make a solid Electrolytic capacitors.

[0050] In this solid electrolytic capacitor, the electrolyte of the solid electrolyte layer 7 includes polypyrrole, polythiophene, polyaniline, etc., but in order to reduce ESR (equivalent series resistance), polyethylenedihydroxythiophene, which has a small intrinsic resistance, is mainly used.

[0051] This will now be described in more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com