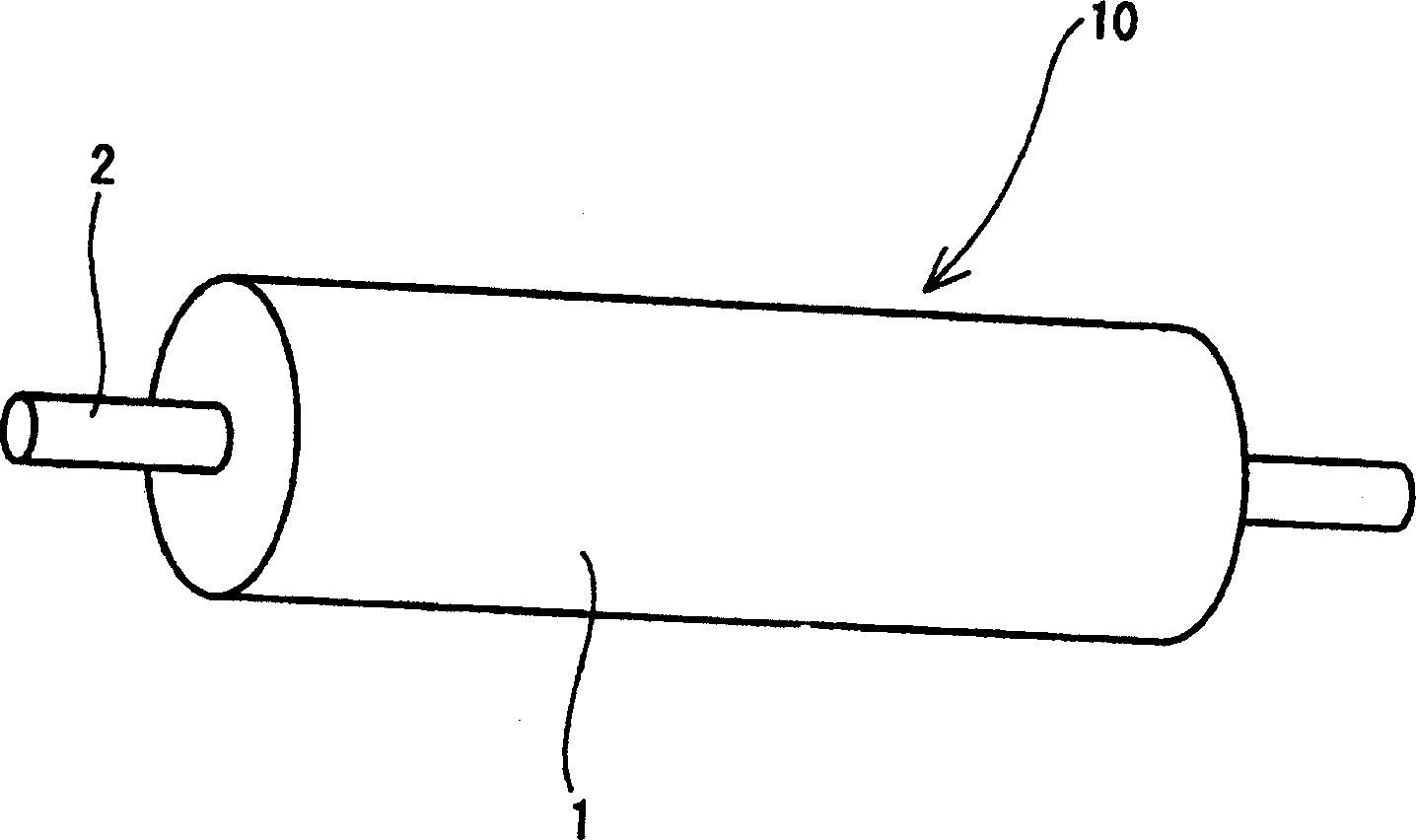

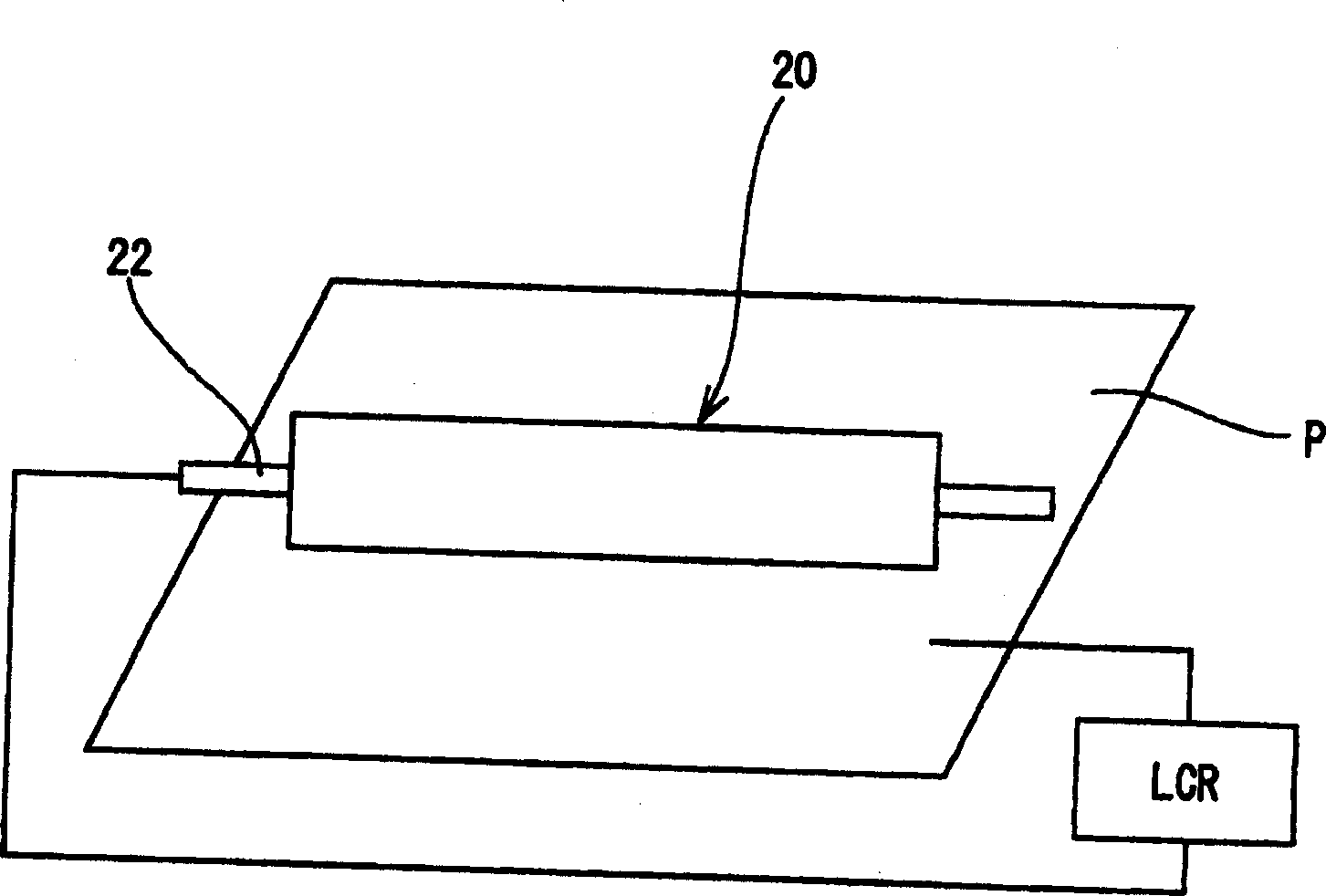

Conducting roller

A conductive roller, conductive technology, applied in the direction of circuits, electrographics, electrical components, etc., can solve the problems of scattering, toner diffusion, toner coating blur, etc., to achieve low resistance, reliable adhesion, Effect of suppressing toner spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 16

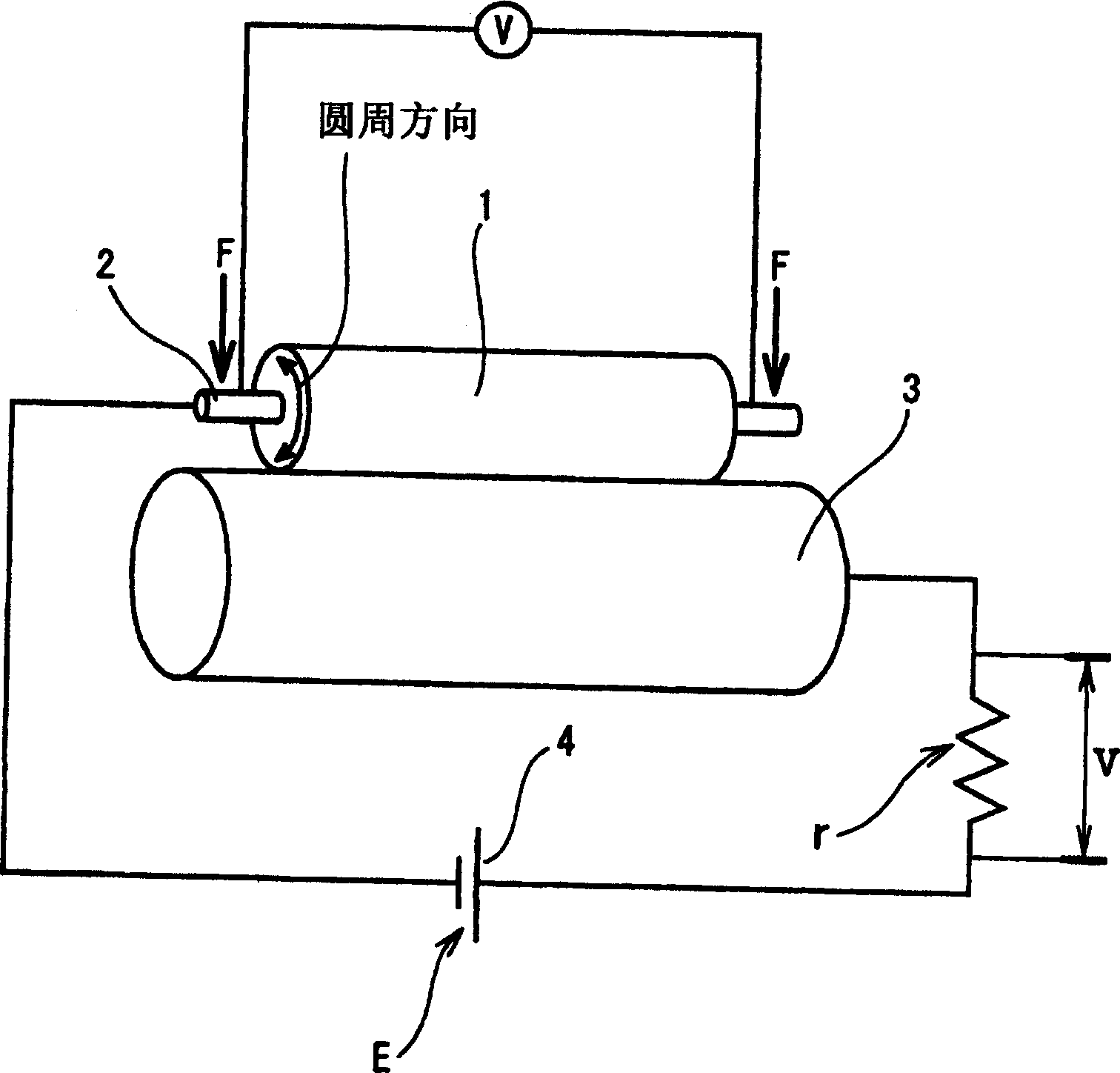

[0071] In any of Examples 1 to 16, as shown in Table 1, the common logarithmic value of the resistance is within the scope of the present invention, and the electrostatic capacitance of the conductive roller at 100 Hz is also 50pF within the scope of the present invention. the following. Examples 1 to 6, 16, using conductive added salt 1; Examples 7 to 10, using conductive added salt 2; Example 11, using conductive added salt 5; Example 12, using conductive added salt 3; In Example 13, the conductive additive salt 4 was used; the type of the conductive additive salt of the salt having an anion having a fluorine group and a sulfonyl group was changed. In Examples 14, 15, no conductive salt was added.

[0072] In Examples 11 to 13 in which the conductive additive salt 3 to 5 were used, the increase in energization can be reduced due to the increase in cations.

[0073] In addition, in Example 16, a salt in which conductive addition salt 1 was mixed in the EO-PO-AGE copolymer in adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com