Vertical tube-gear rack type pumping unit

A rack-type pumping unit technology, which is applied in the fields of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as difficulty in manufacturing and installation, impact on service life, and heavy maintenance workload, and achieve Easy to manufacture and install, prolong service life, and short transmission line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

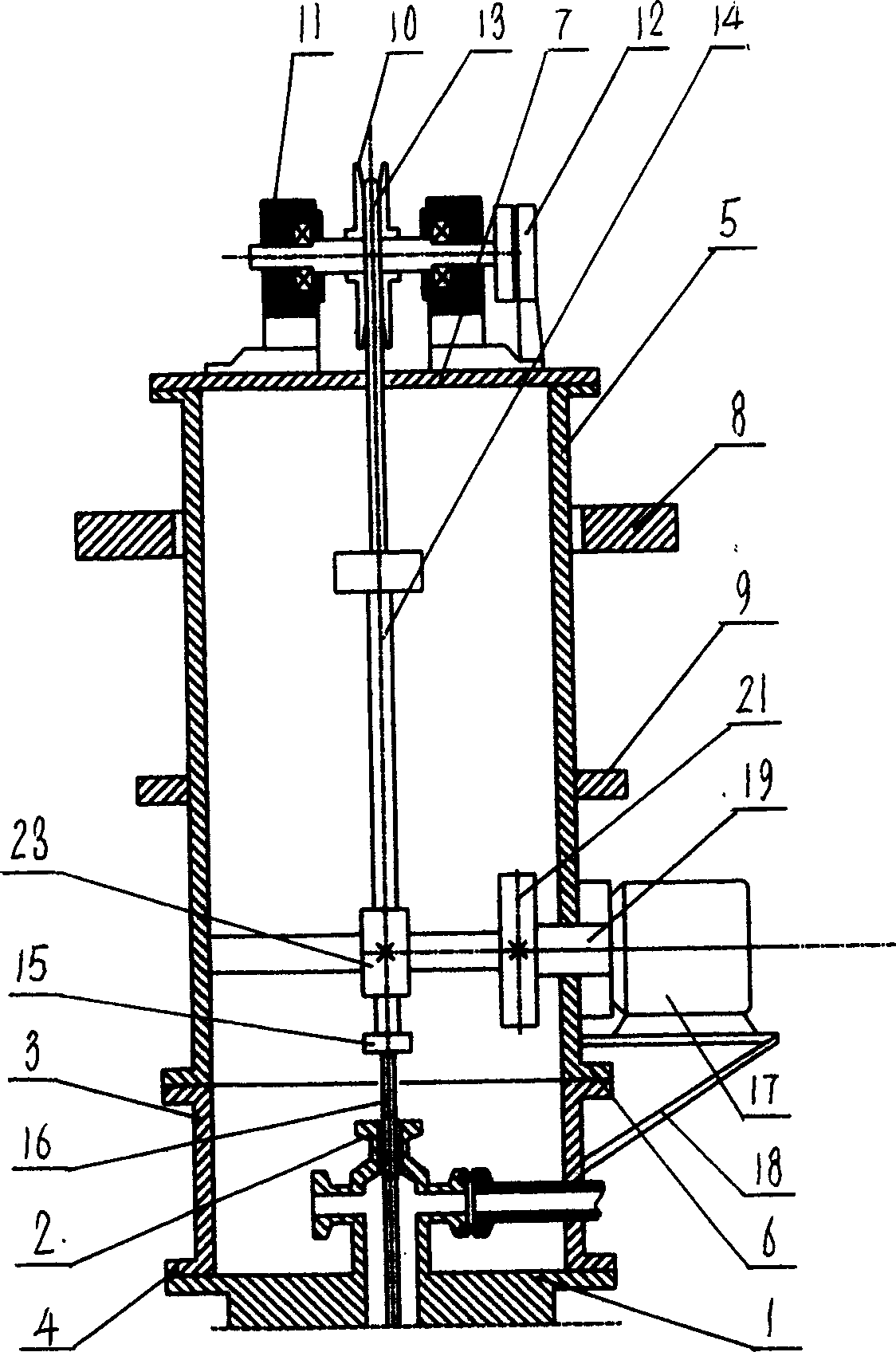

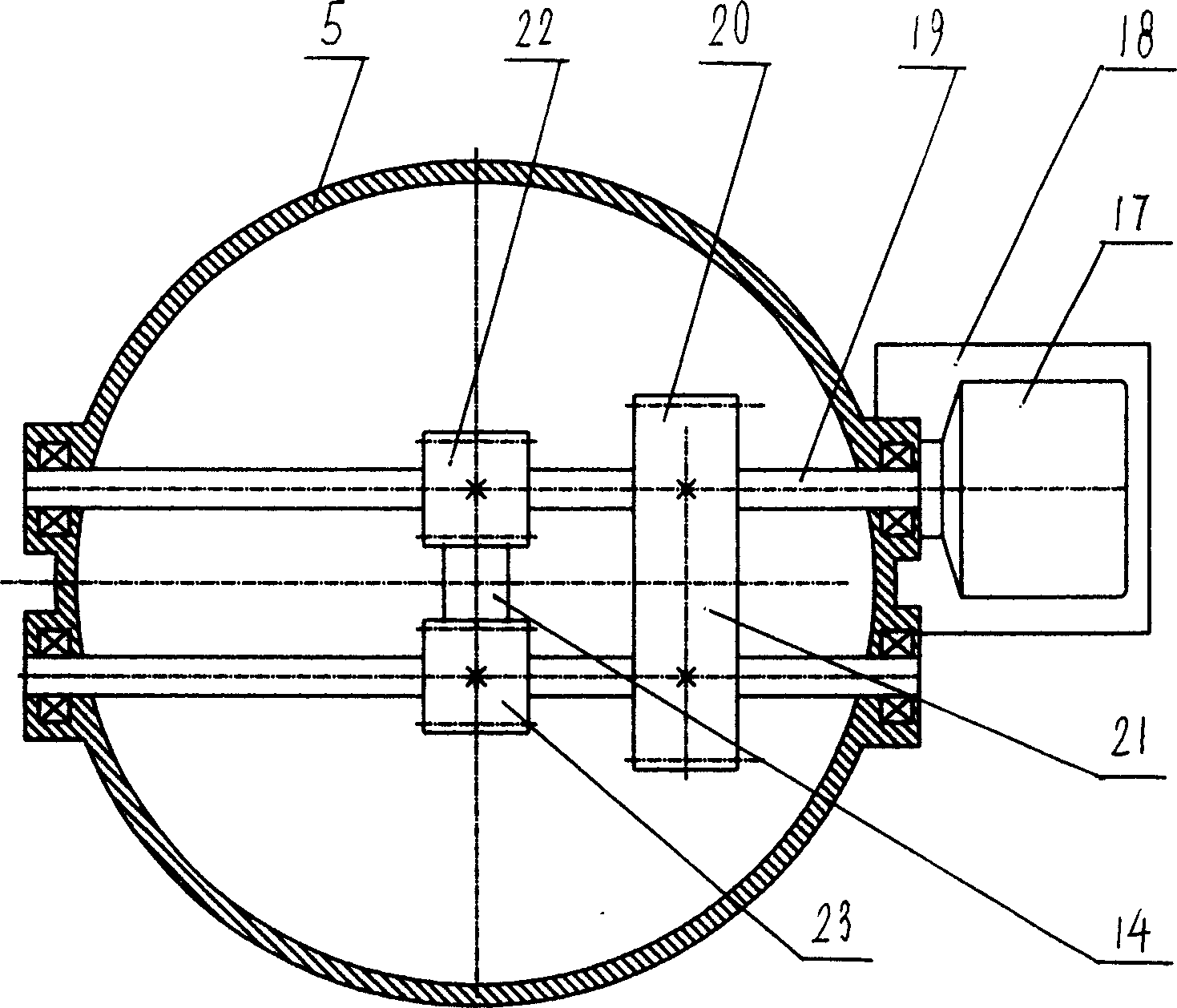

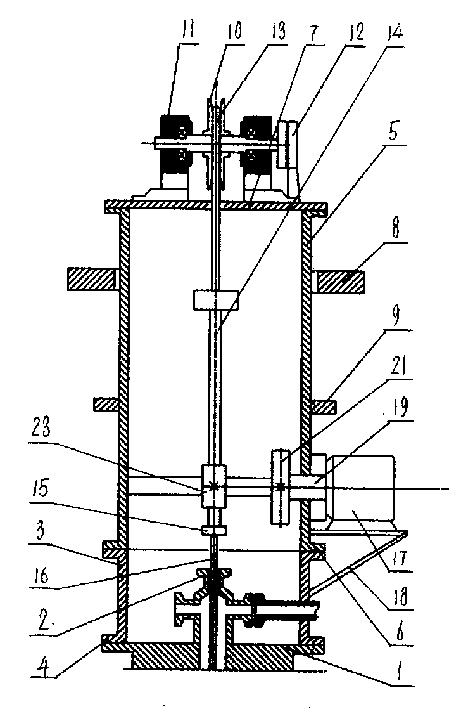

[0008] Such as figure 1 and figure 2 As shown, the standpipe type rack pumping unit of the present invention is mainly composed of a wellhead cross, a wellhead nipple, a standpipe, an overhead wheel, a suspension rope, a rack, a sucker rod and a transmission mechanism. The wellhead cross 1 is installed and fixed on the oil wellhead, and its center is provided with an oil production wellhead 2. The wellhead nipple 3 is located on the wellhead cross 1 and connected to the wellhead cross 1 through the flange 4; there is a movable door on its side, and the wellhead 2 can be maintained by opening the movable door. The standpipe 5 is located on the wellhead sub-joint 3 and connected with the wellhead sub-joint 3 through the flange 6, the top of which is provided with a standpipe cap 7, and its periphery is provided with an annular balance weight 8 which can slide up and down along the standpipe 5; The outer wall of the riser 5 below the weight 8 is provided with an anti-collision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com