Small size Low Nox gas burner equipment and method

A gas burner and burner technology, applied in the direction of gas fuel burners, combustion equipment, combustion methods, etc., can solve the problems of large burner equipment, long flame, and low regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

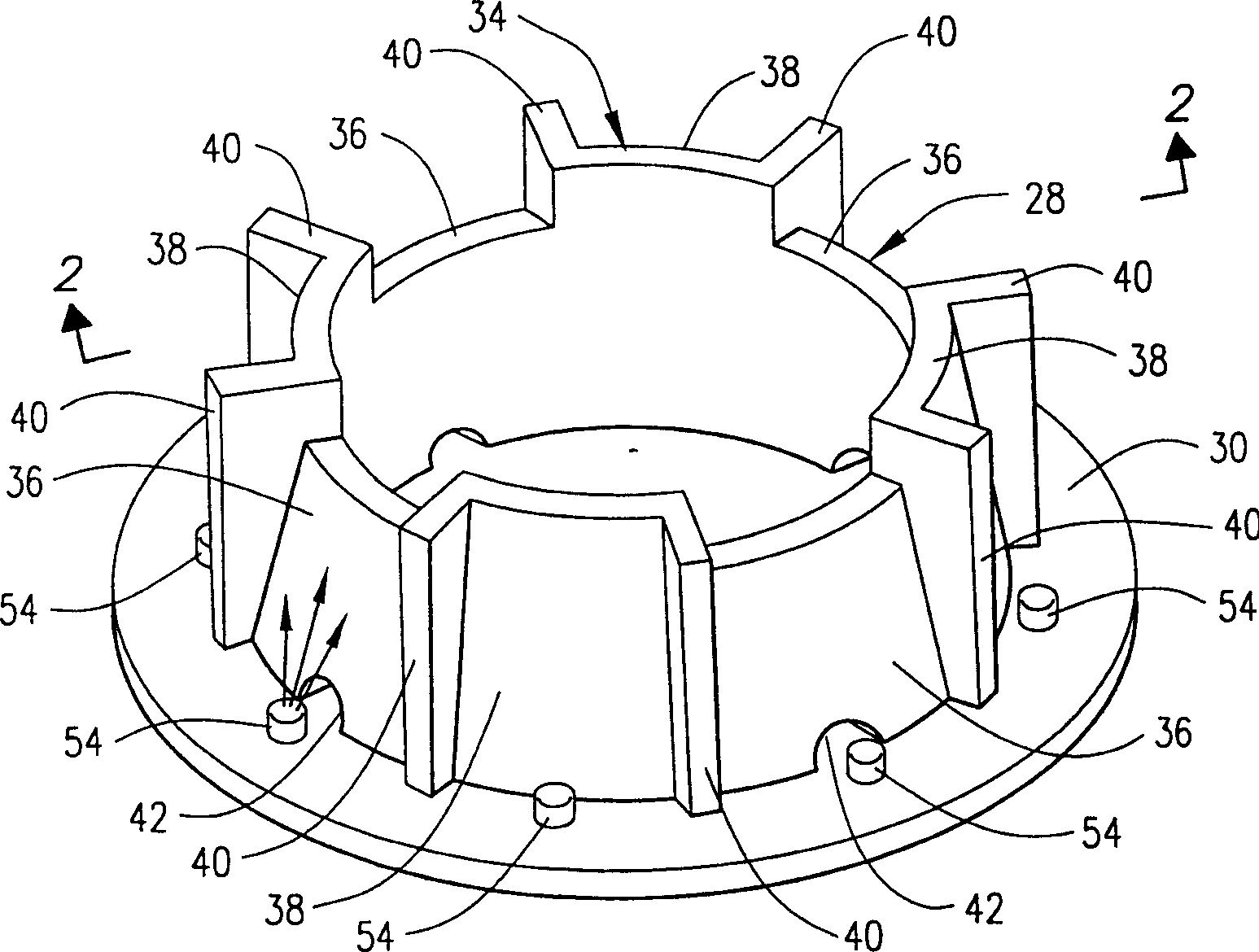

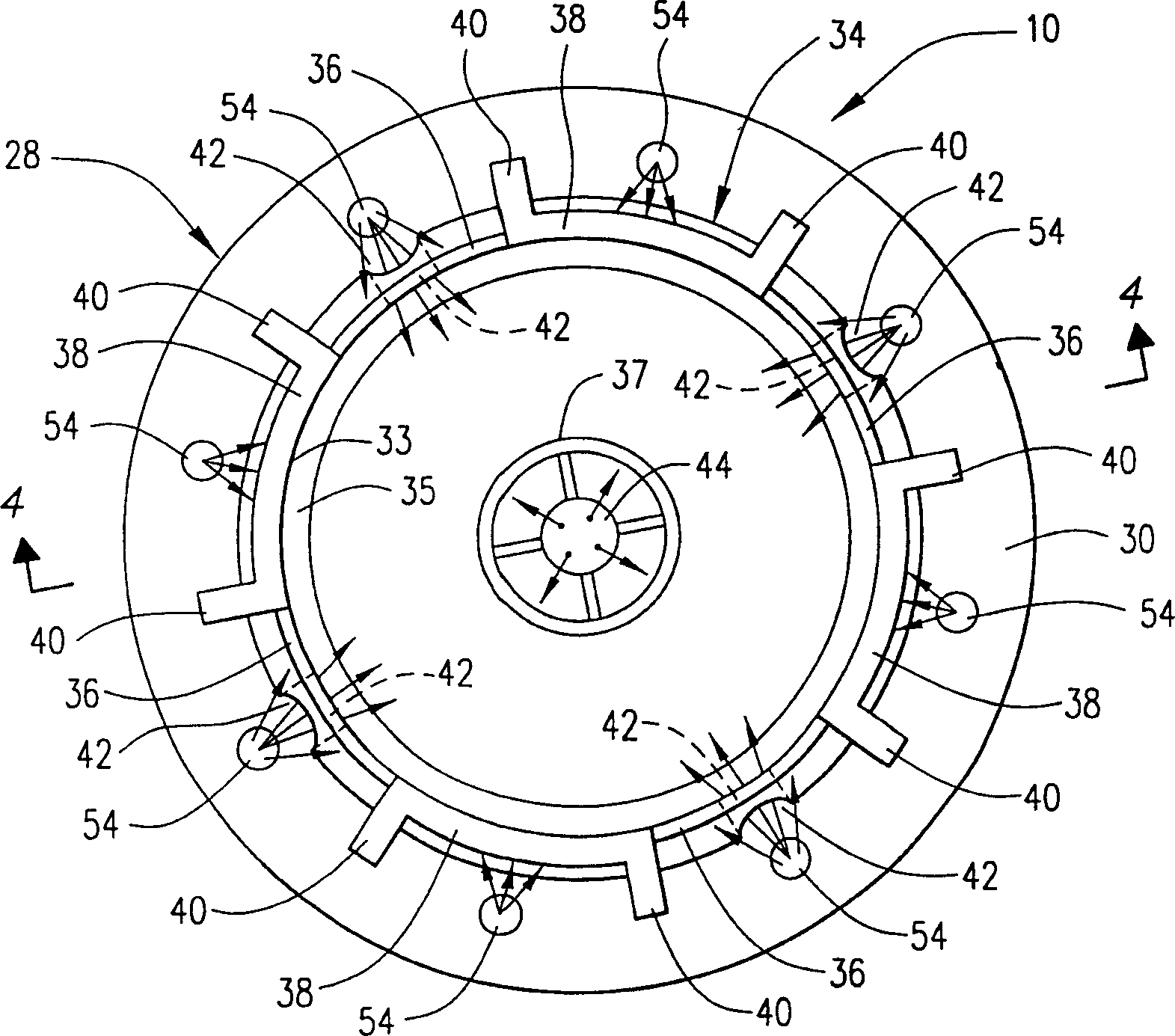

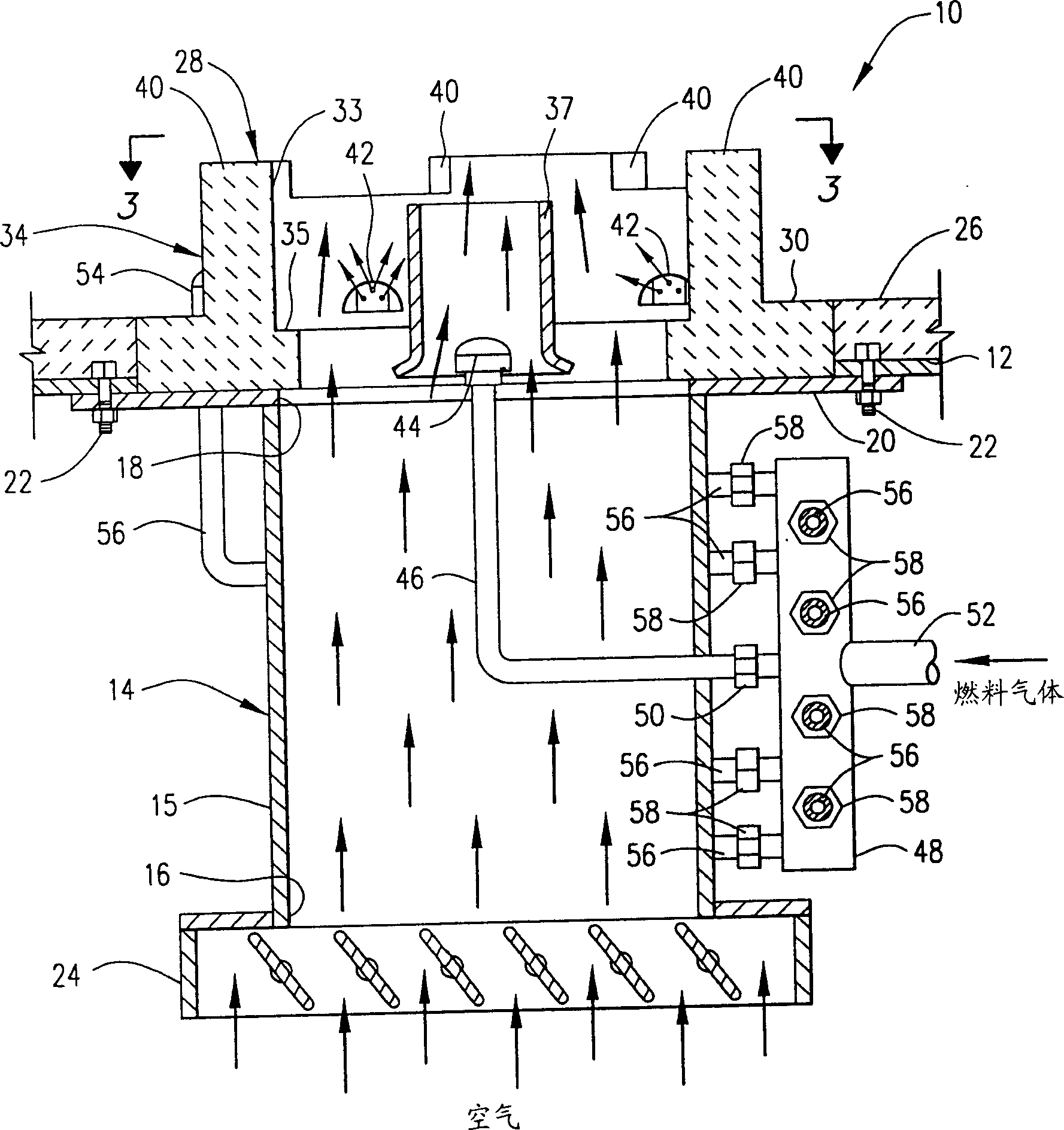

[0035] The burner device 10 is designed to release 8 million BTU of heat per hour by burning natural gas with a calorie value of 913 BTU / SCF, so that the burner device 10 is burned into the furnace space. The pressurized fuel gas is supplied to the pipe 48 of the combustor 10 at a pressure of approximately 33 psig and a flow rate of approximately 8765 SCF / hour. The 20% volume part (1753SCF / hour) of the fuel gas is used as the first fuel gas and is discharged into the hole 32 and the burner tile 28 through the fuel gas discharge nozzle 44 and through the fuel gas discharge nozzle 54. The fuel gas discharges The nozzle 54 is arranged near the hole 42 in the wall 40 of the burner tile 28. The remaining part of the fuel gas (ie, the second part) is discharged into the furnace space at a rate of 7012 SCF / hour through the nozzle 54 as a separate fuel gas stream mixed with the exhaust gas.

[0036]The rate of air introduced into the furnace space through the air conditioner 24, the housi...

Embodiment 2

[0038] In order to see the flame pattern produced by the burner device 10 while operating as described in the above embodiment 1, a computer simulation program was used. The software used can be obtained from Fluent Inc. Of Lebanon, New Hampshire, USA. In the simulation program, the burner design can be reconstructed in all three-dimensional details, including all important features such as tile surface, fuel gas perforation, flame stabilizer tile shoulder and complete air chamber structure.

[0039] The three-dimensional model of the furnace in which the burner equipment was tested was installed in the furnace model, except that the air entered from the side instead of from the bottom. The furnace model was exactly the same as the test burner and furnace used in Example 1. . The finite volume method is used to divide the flow space in the combustor model into many small volumes, and boundary adjustments such as fuel pressure, flow rate, etc. are used at the inlet of the combustor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com