Grinding seed roast for nutritive use

A roasting and seed technology, applied in the field of coffee seeds, can solve the problems of mutagenicity of mammalian cells, loss of volatile substances, and uniform roasting of seeds that cannot be processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

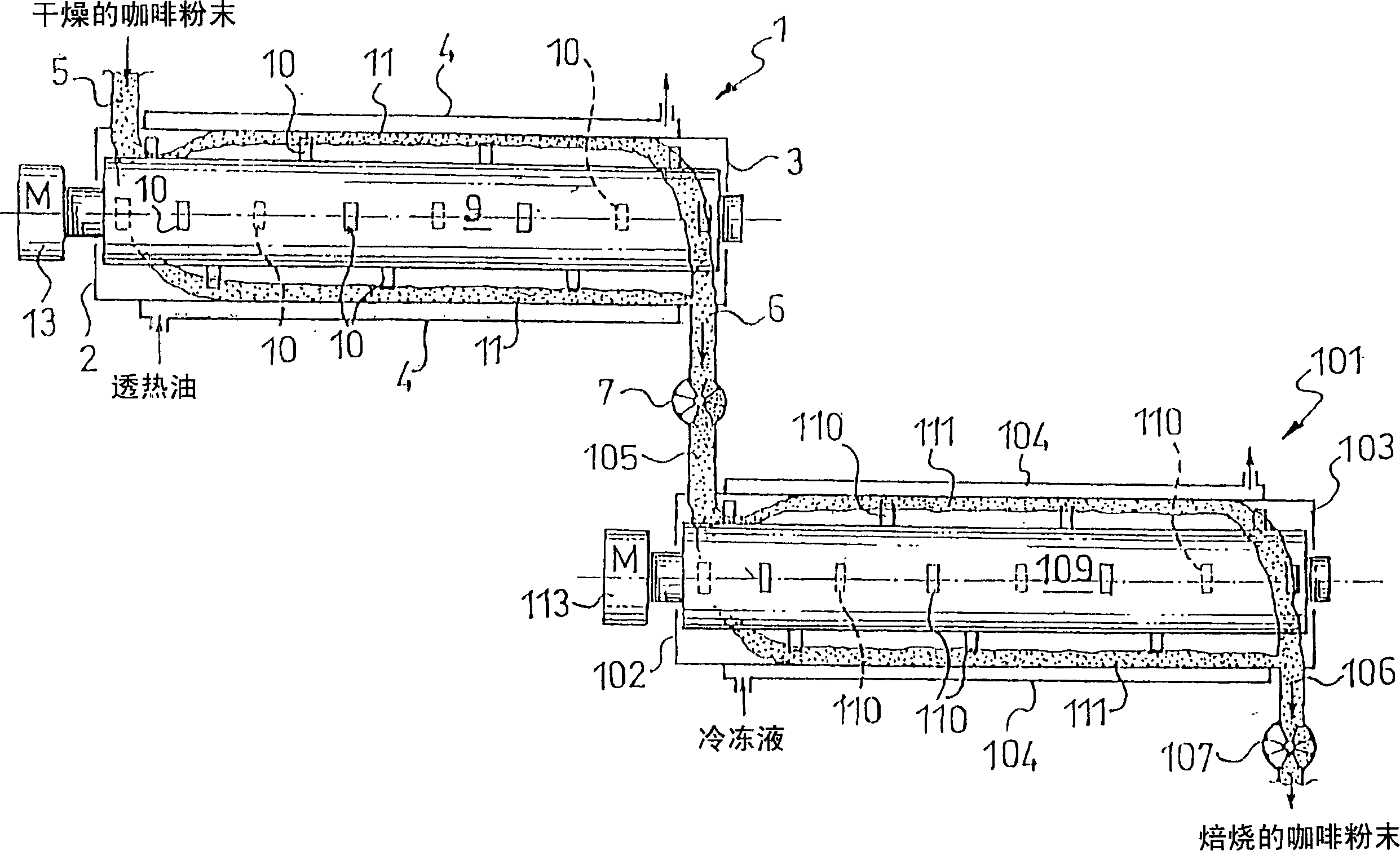

[0072] Carrying out the method according to the invention and using the apparatus described above, the roaster 1 is supplied continuously at a rate of 100 kg / h with coffee powder from seeds ground to an average particle size of 1 mm and dried to a moisture content of 5 %.

[0073] The wall temperature of the roaster 1 was controlled at about 180°C and the bladed rotor was driven at a constant rate of 800 RPM.

[0074] After a residence time of about 3 minutes, the roasted powder and roasted smoke are transferred to a condenser 101 whose wall temperature is controlled at about 0°C and whose rotor is driven at the same speed as that of the roaster 1 .

[0075] The condenser 101 is connected to an exhaust fan which discharges a portion of the roasted smoke which does not condense at its temperature.

[0076] After a residence time of about 5 minutes in the condenser 101 , the finished product was discharged with a water content of 3%.

Embodiment 2

[0078] Carrying out the method according to the invention and using the apparatus described above, the roaster 1 is supplied continuously at a rate of 100 kg / h with coffee powder from seeds ground to an average particle size of 2 mm and dried to a moisture content of 10 %.

[0079] The wall temperature of the roaster 1 was controlled at about 190°C and the bladed rotor was driven at a constant rate of 900 RPM.

[0080] After a residence time of about 5 minutes, the roasted powder and roasted smoke are transferred together to the condenser 101, the wall temperature of which is controlled at about -2°C, and the drive speed of the rotor equipped with blades is the same as that of the roaster 1 with the same rotor drive speed.

[0081] The condenser 101 is connected to an exhaust fan which discharges a portion of the roasted smoke which does not condense at its temperature.

[0082] After a residence time of about 6 minutes in the condenser 101 , the finished product was dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com