Response operator for gasifying solid fuels

A technology of gasification reaction and solid fuel, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of high cost and low gasification efficiency, achieve the effect of improving gasification efficiency and reducing the cost of gasification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

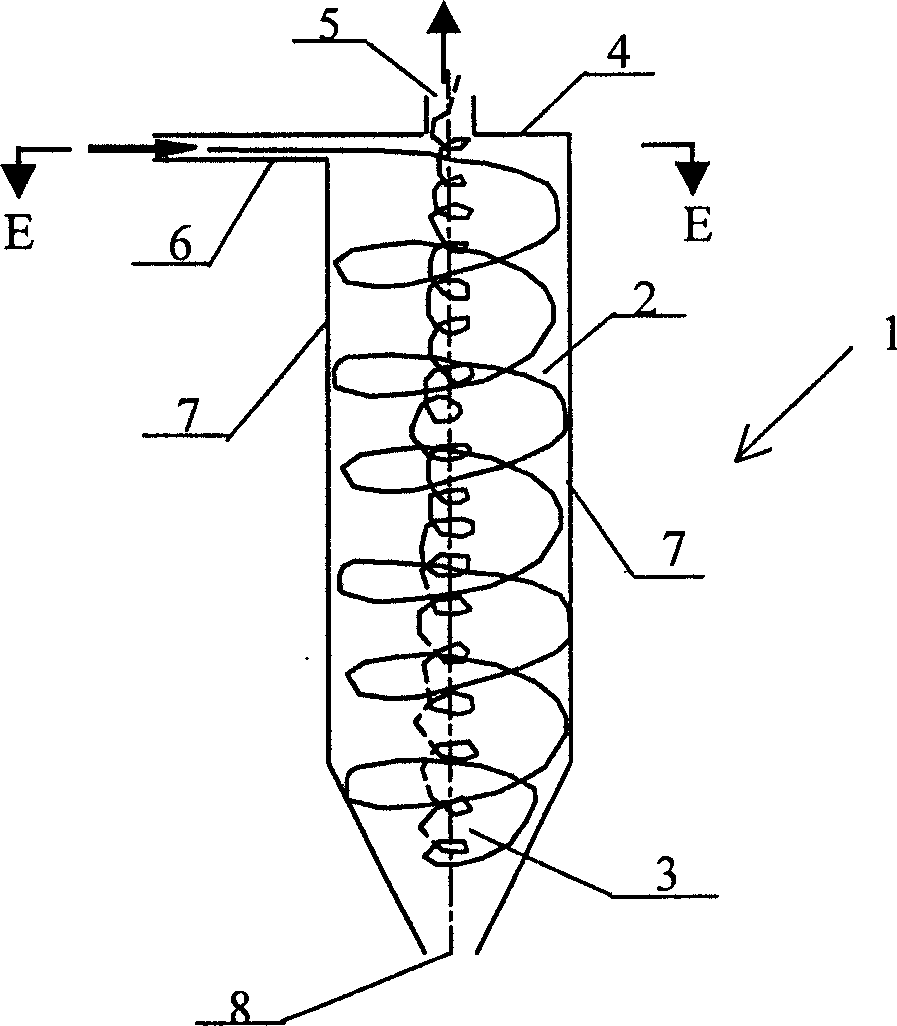

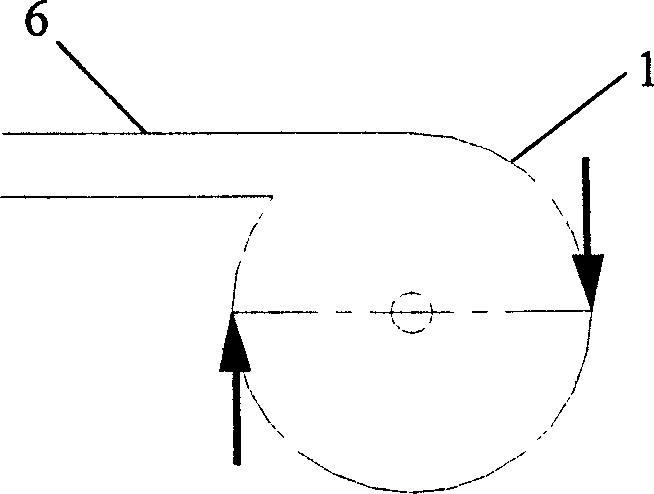

[0028] Such as figure 1 The gasification reaction device of a kind of solid fuel of the present invention shown, comprises the cyclone furnace 1 of high-temperature stainless steel material; 20:1; the lower part 3 is in the shape of a conical cylinder, the diameter of its upper end is 100 mm, and it is seamlessly connected with the lower end of the cylinder of the upper part 2, and its bottom end is provided with a row of ash ports 8; the top part of the upper part 2 There is a top cover 4, and an exhaust pipe 5 is arranged at the center of the top cover 4; a solid gas inlet channel 6 along the tangential direction of the side wall is arranged on the side wall of the cyclone furnace 1 close to the top cover 4; The wall is provided with four first air supply passages 7 (not all of which are marked in the figure) along the tangential direction of the side wall, which are located below the solid gas inlet passage 6 .

[0029] Here, the aspect ratio of the upper part 2 of the cyc...

Embodiment 2

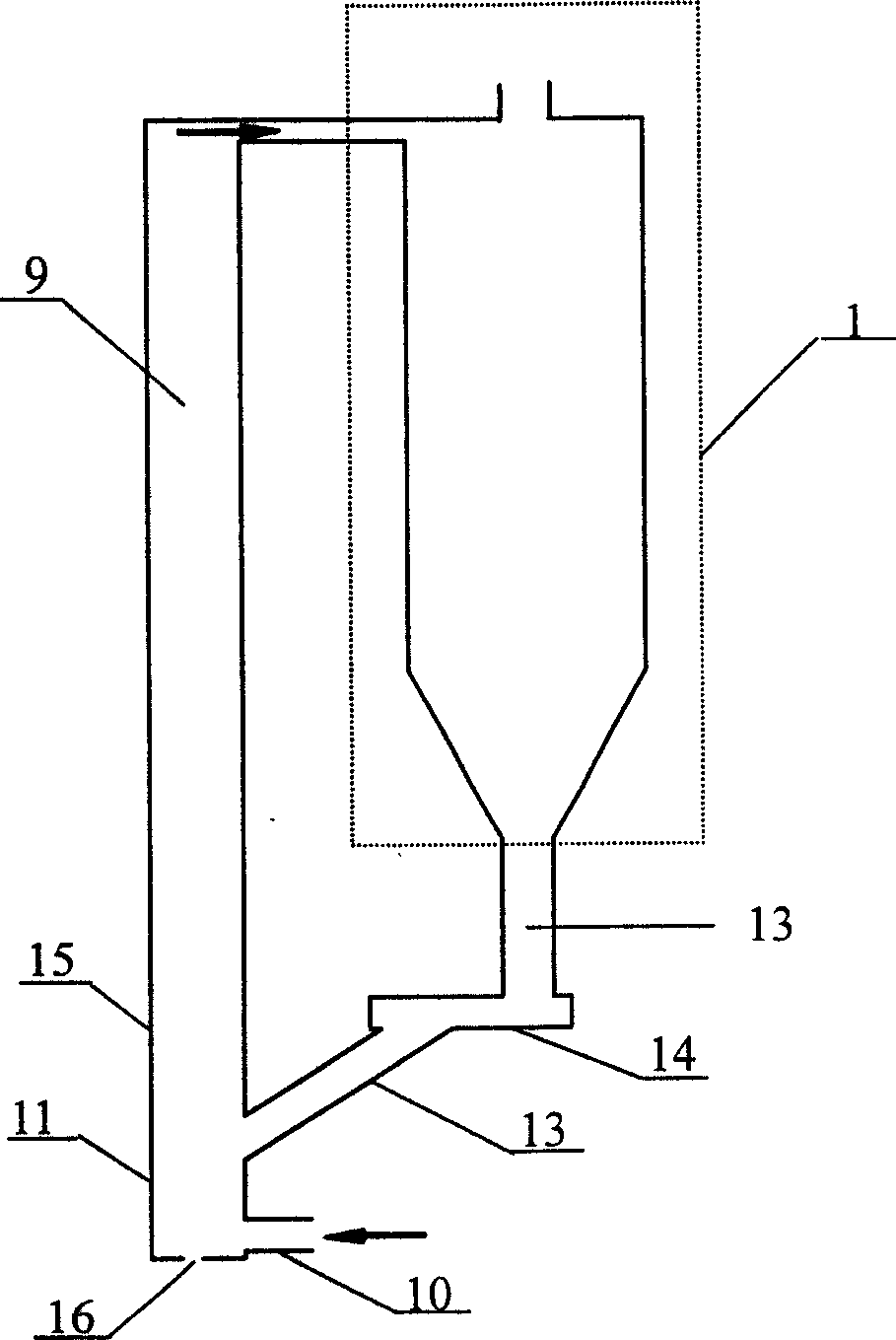

[0032] Such as image 3 A solid fuel gasification reaction device of the present invention shown includes a cyclone furnace 1 and a riser 9; the structure of the cyclone furnace 1 is the same as that in the embodiment 1. The riser 9 includes a top cover; the uppermost side wall of the riser 9 communicates with the solid gas inlet passage 6 of the cyclone furnace through a connecting pipe; an air inlet passage 10 is opened on the side wall of the bottom end of the riser pipe 9; the air inlet passage 10 A solid fuel feed port 11 is opened on the side wall of the riser above, and is close to the bottom of the riser 9 . There is a material return port 12 above the air inlet channel 10 on the side wall of the riser 9, and a material return channel 13 is provided between the material return port 12 and the ash discharge port 8 of the cyclone furnace; the material return channel 13 is provided with a L type valve 14, other types of non-mechanical valves can also be used, such as F...

Embodiment 3

[0035] The solid fuel gasification reaction device in this embodiment is similar to that in Embodiment 2, except that two parallel cyclone furnaces are used in this embodiment. Such as Figure 4 As shown, it includes a riser 9, a cyclone furnace 1 and a second cyclone furnace 1'; the riser 9 is connected to the solid gas inlet channel 6 of the cyclone furnace 1 and the second solid gas inlet channel 6' of the second cyclone furnace 1' respectively Pass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com