Laminated heat exchanger

A heat exchanger and heat transfer tube technology, which is applied in the field of stacked heat exchangers, can solve the problems that the cooling and dehumidification of the exhaust air cannot be carried out smoothly, the temperature distribution difference of the exhaust air is increased, and the air heat exchange cannot be realized. The effect of uniform outlet surface temperature and discharge air temperature, improved cooling effect, and prevention of supercooled area and superheated area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be specifically described below with reference to the accompanying drawings.

[0073] Meanwhile, the description of the same parts as the related art is omitted.

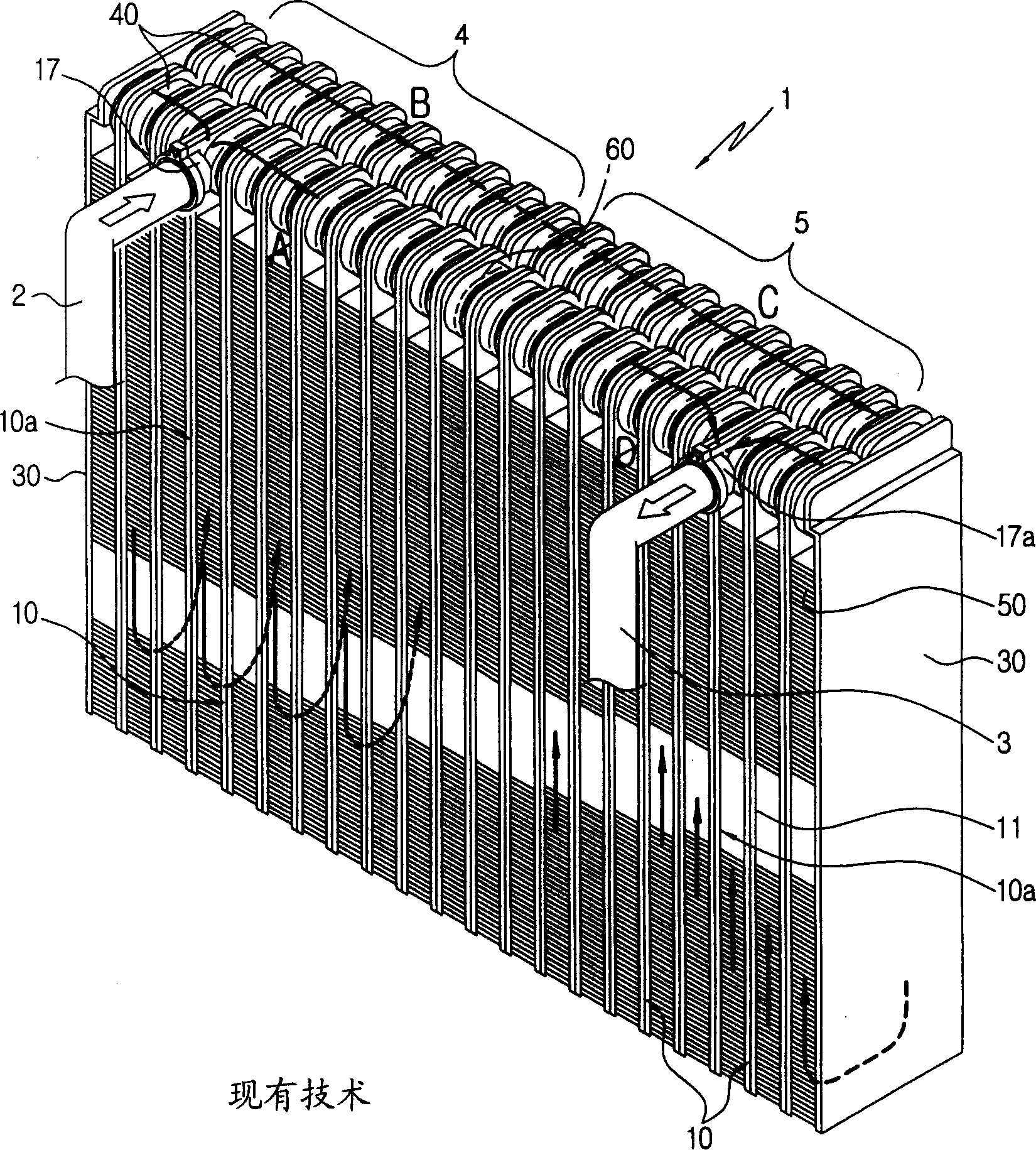

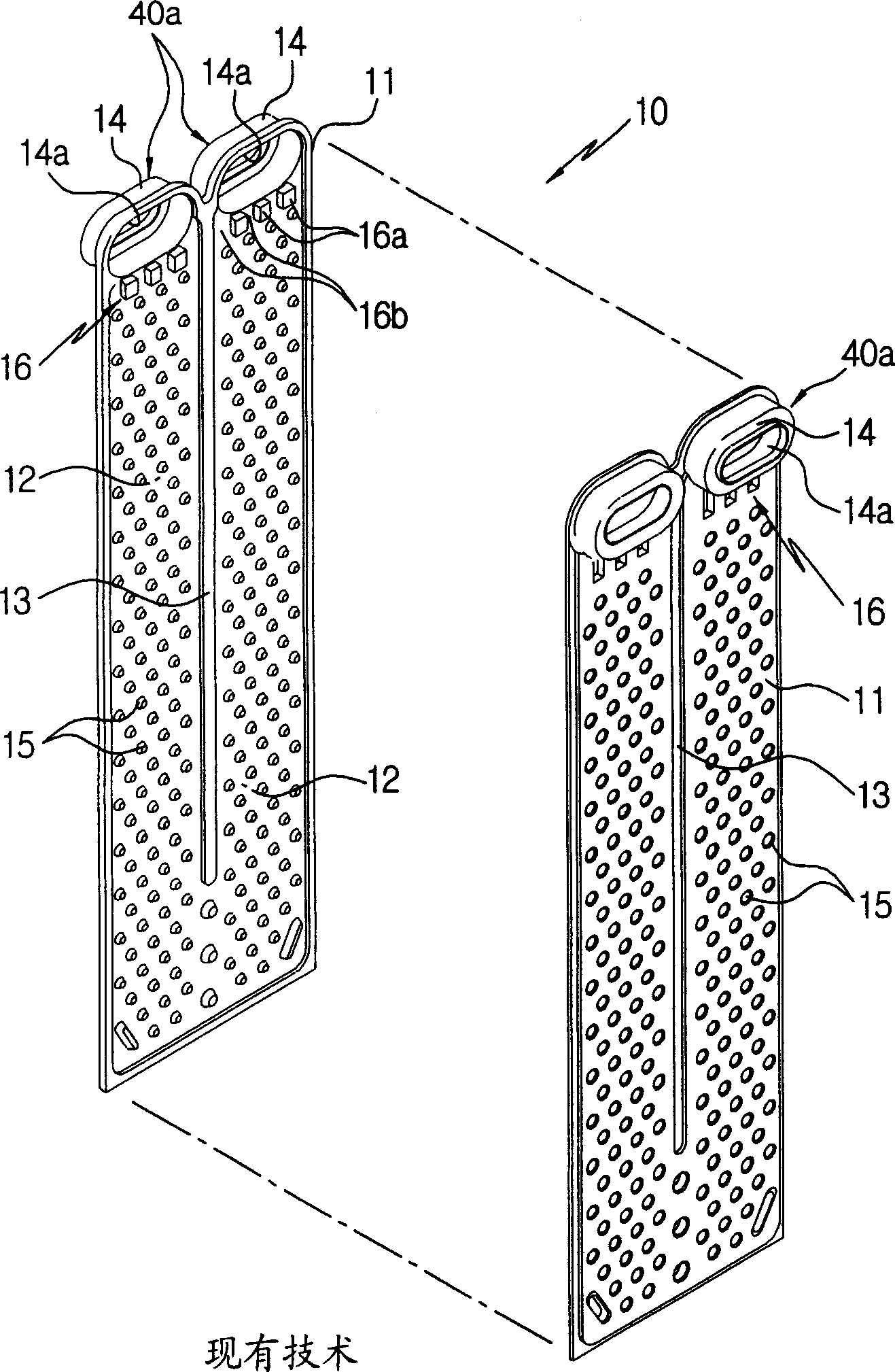

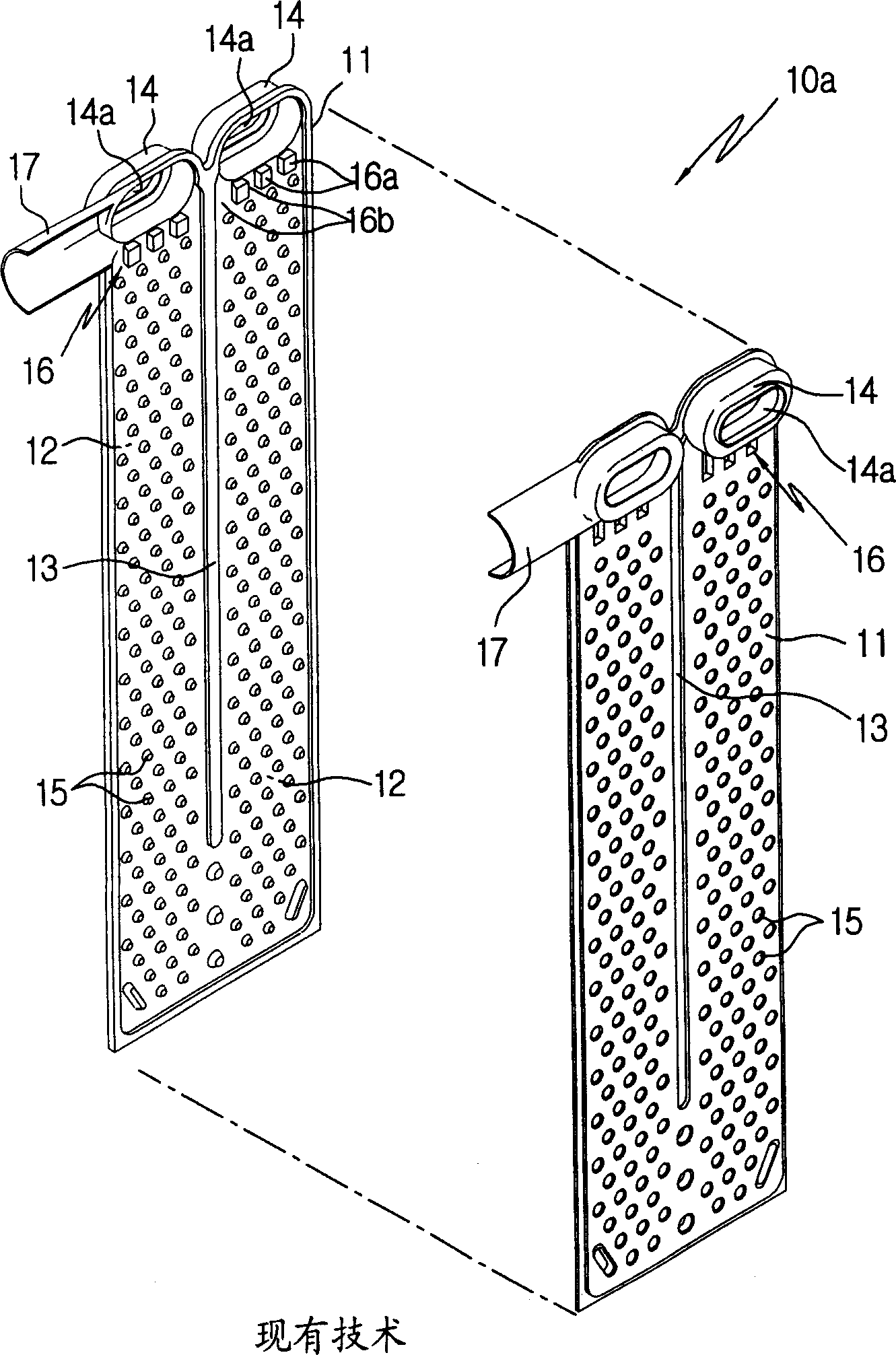

[0074] Figure 7 To represent the oblique view of the evaporator of the present invention, Figure 8 It is a perspective view showing the separated state of the heat transfer tube with manifold of the present invention, Figure 9 It is a diagram showing a state where the two outermost distribution channels of the refrigerant distribution part on the inlet and outlet sides are cut off by a bead in the heat transfer tube with a manifold of the present invention, Figure 10 It is a perspective view showing the separated state of the common heat transfer tube of the present invention, Figure 11 It is a diagram showing a state where the two outermost distribution channels of the refrigerant distribution part on the inlet and outlet sides are partitioned by beads in the general heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com