Fixed point jet flow air supply system

An air supply system and jet technology, applied in the field of fixed-point jet air supply system, can solve the problems of air quality decline, insufficient fresh air volume, and inability to meet the comfort requirements of staff well, so as to improve air quality and thermal comfort. Sex and air quality, the effect of avoiding lateral transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

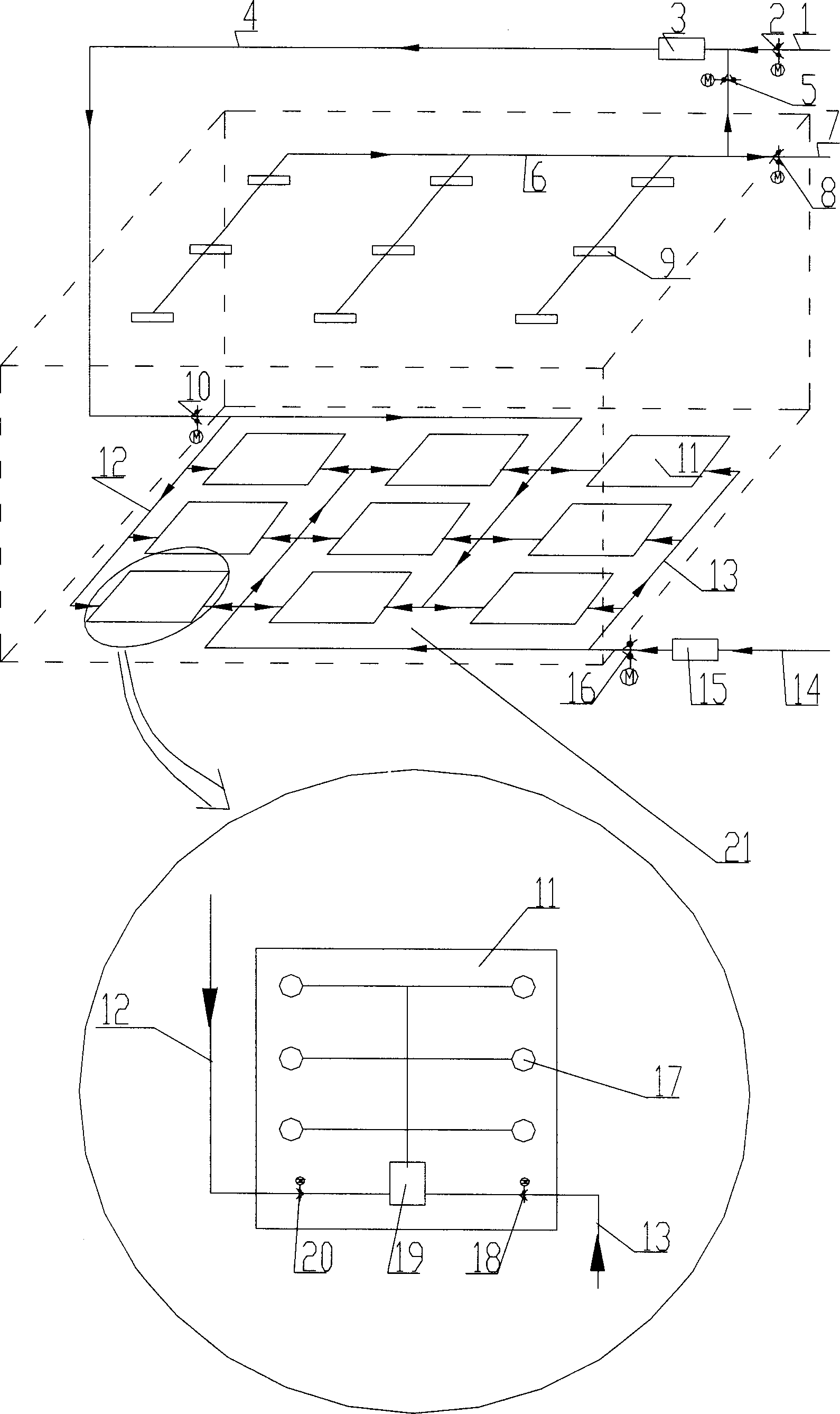

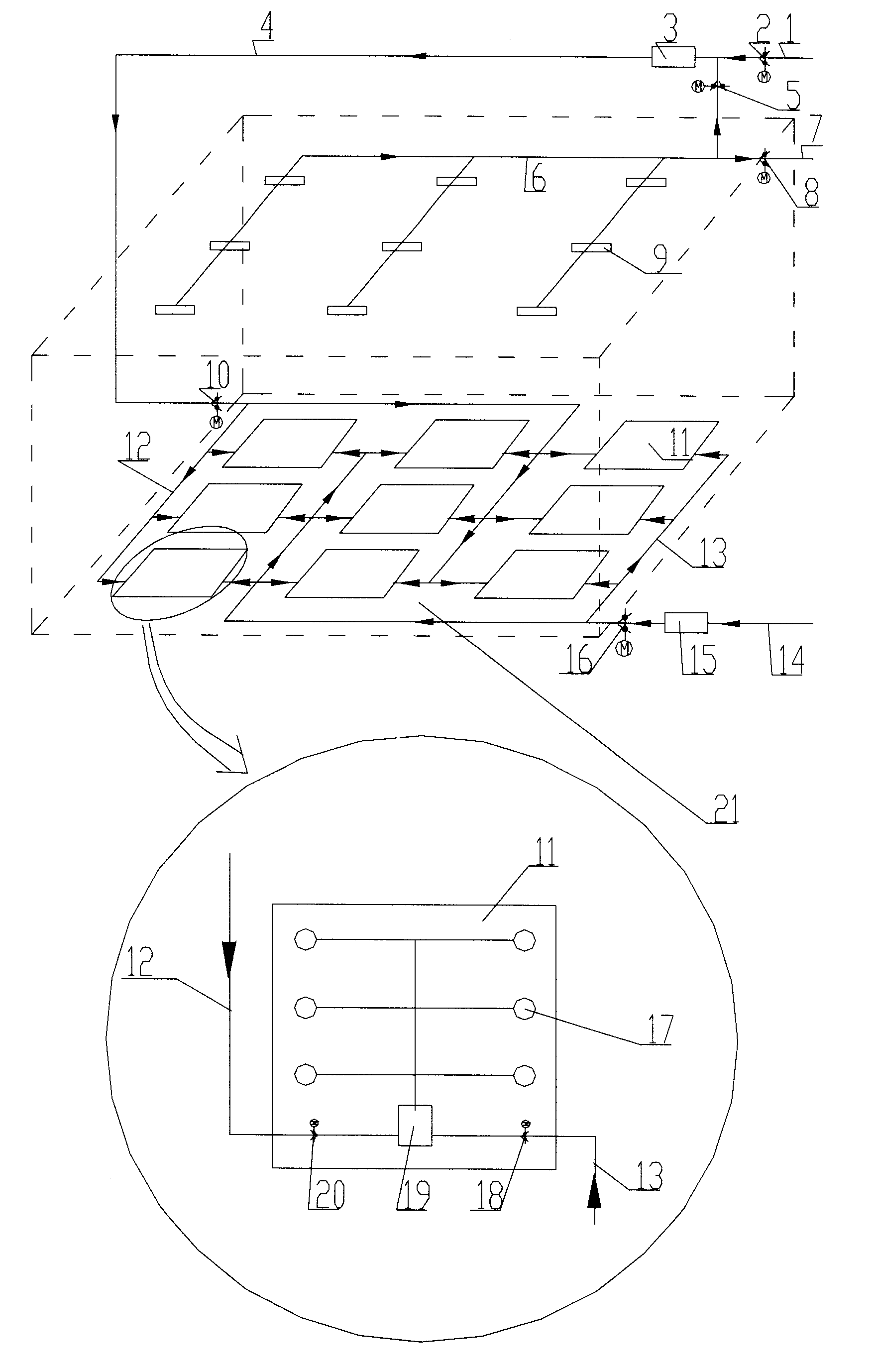

[0009] The fixed-point jet air supply system has fresh air pipe 1, fresh air valve 2, air processor 3, cold air pipe 4, cold air pipe main valve 10, cold air pipe branch 12, fixed-point control area 11, natural ventilation branch 13, natural ventilation main Valve 16, natural ventilation fan 15, natural ventilation pipe 14, fresh air valve 2 are respectively connected to exhaust valve 8, return air port 9, and return air pipe 6 through return air valve 5, and exhaust valve 8 is connected to exhaust pipe 7 .

[0010] The fixed-point control area 11 has in turn a cold air pipe branch 12, a cold air valve 20, an air mixing box 19, a natural wind valve 18, and a natural ventilation branch 13. The air mixing box 19 is connected to the air outlet 17

[0011] The fixed-point jet air supply system can be composed of multiple or one working area, and one working area is composed of multiple or one fixed-point control area. Each fixed-point control area is equipped with a set of air su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com