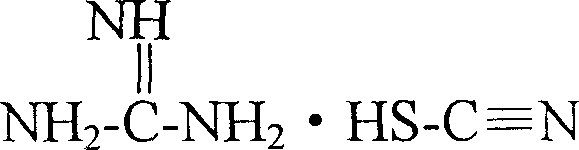

Prepn of guanidyl thiocyanate

A technology of guanidine thiocyanate and ammonium thiocyanate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of low product purity and achieve good quality, high purity and reasonable principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

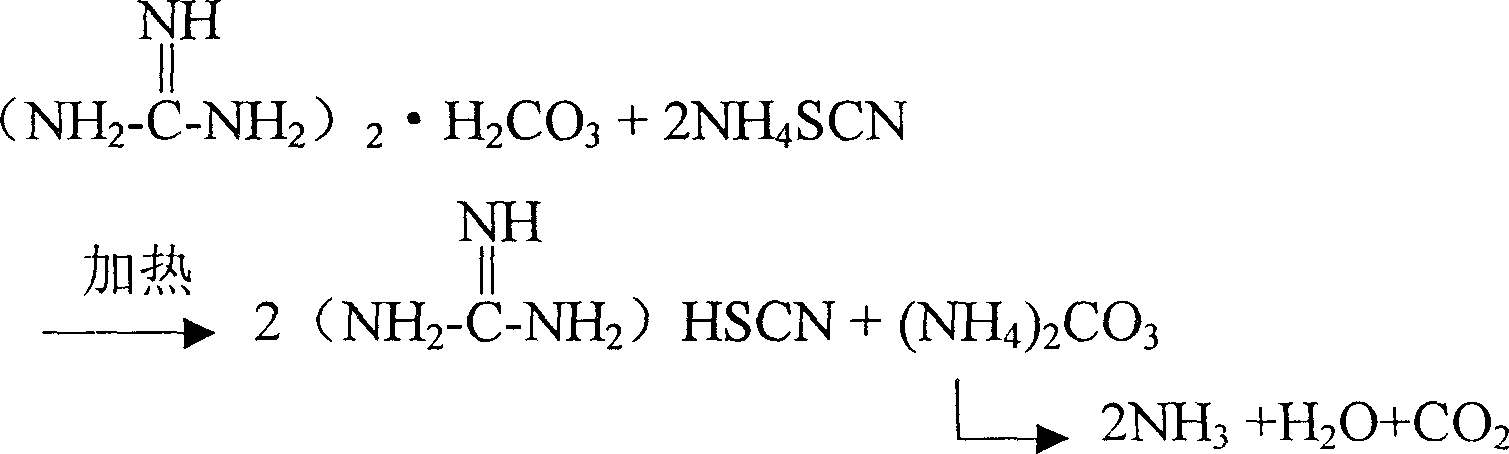

Method used

Image

Examples

Embodiment Construction

[0017] A kind of preparation method of guanidinium thiocyanate, has following technological process: a, put guanidinium carbonate and ammonium thiocyanate that weight ratio is 2: 1 into reactor, react at 50~90 ℃ for 2 hours, get thiocyanate Guanidine acid crude product.

[0018] B, dissolving, at normal temperature, by the ratio of 1: 1 crude guanidine thiocyanate is dissolved in water;

[0019] c. Filtration to remove impurities such as raw materials and reaction by-products by filtration;

[0020] d, dehydration, the mother liquor after filtering is dehydrated at high temperature;

[0021] e, crystallization, supersaturated solution cooling, concentrated crystallization, obtained high-purity guanidine thiocyanate.

[0022] Further: the guanidinium thiocyanate after the e step is passed through b, c, d, e steps again, wherein the ratio with water is 1: 1 in the b step, obtains the guanidine thiocyanate of higher purity, and as required This step can be repeated multiple ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com