Dielectric ceramic and producing method thereof, and multilayer ceramic capacitor

A technology of dielectric ceramics and multi-layer ceramics, applied in the field of dielectric ceramics and their preparation, can solve problems such as unstable reaction, reduction of capacitance-temperature characteristics and reliability of dielectric ceramics, reduction of thickness of dielectric ceramics layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

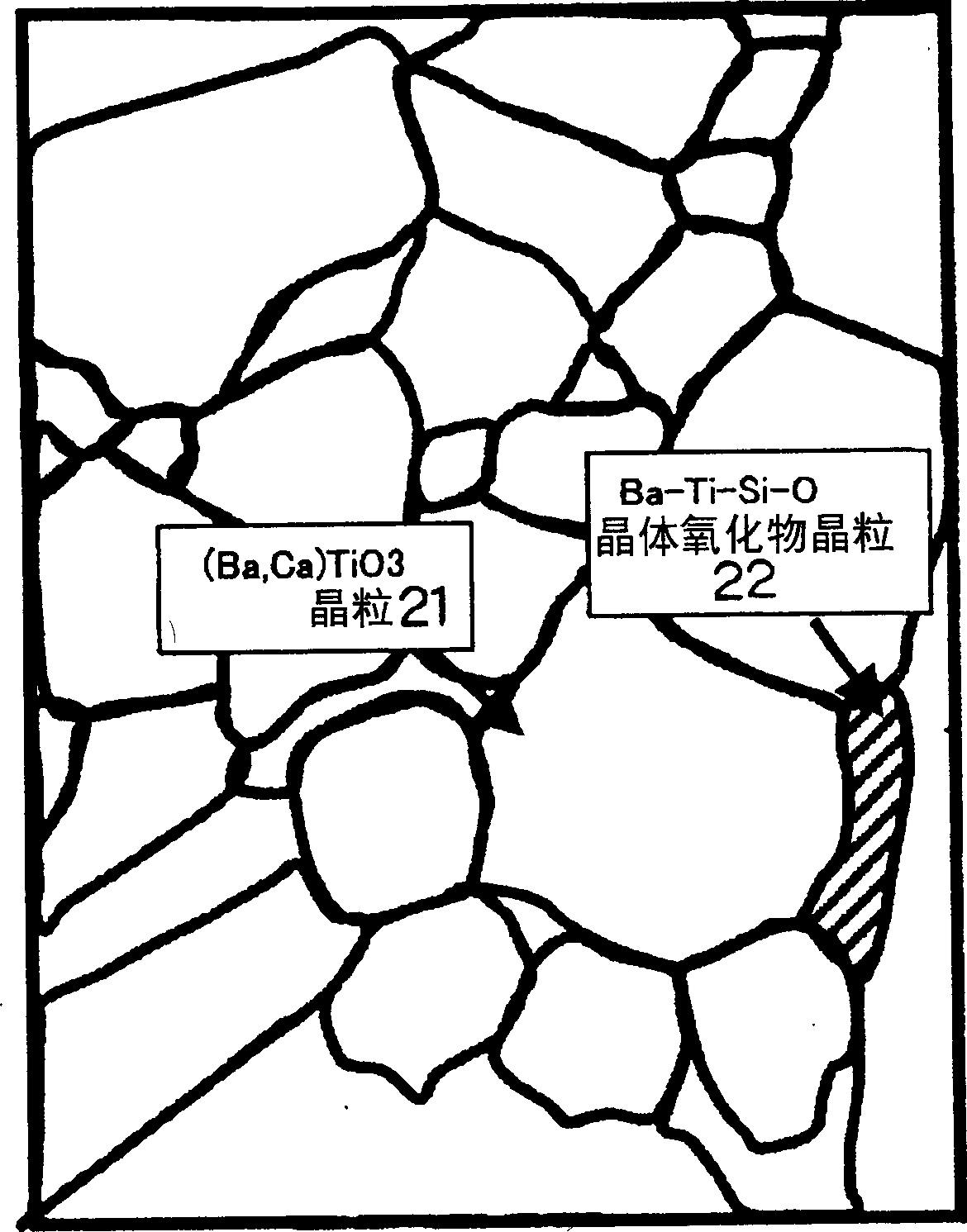

[0075] In embodiment 1, as shown in table 1, use ABO 3 As main components, it includes Ba, Ca and Ti and has (Ba 0.93 Ca 0.07 )TiO 3 composition, and with BaCO 3 、TiO 2 and SiO 2mixture or Ba-Ti-Si-O crystal oxide as its additive component. By using these components, Examples 1-1 and 1-2 according to the present invention and Comparative Examples 1-1 and 1-2 other than the present invention were evaluated.

[0076] 1. Formation of powdered raw materials for dielectric ceramics.

Embodiment 1-1

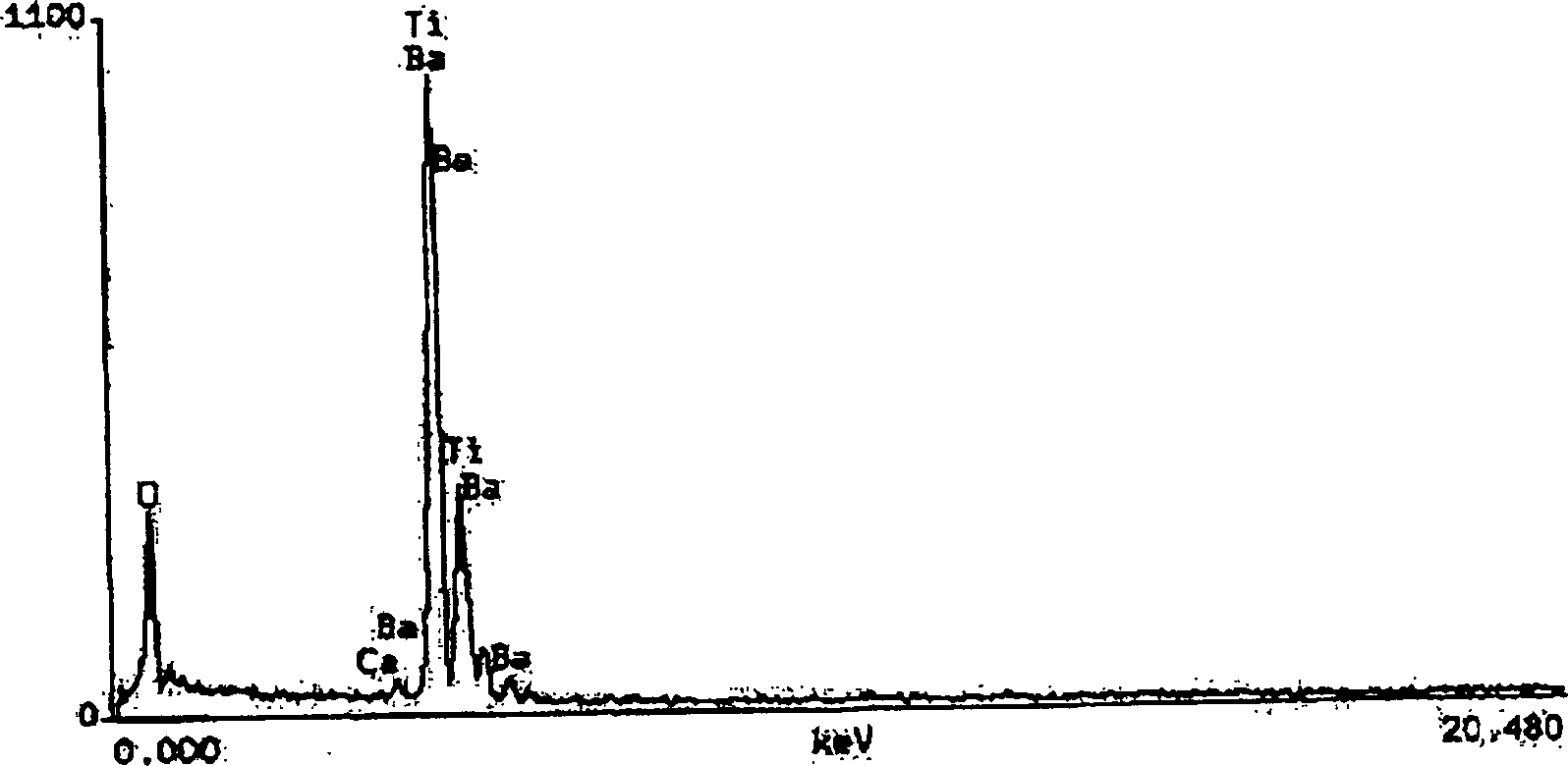

[0078] First, for the raw materials of the main components, in order to form (Ba 0.93 Ca 0.07 )TiO 3 Composition, weigh BaCO by volume 3 , CaCO 3 and TiO 2 , which are then mixed together using a ball mill, followed by heat treatment at 1,050°C, thereby forming (Ba 0.93 Ca 0.07 )TiO 3 . The average diameter of the crystal grains was 0.3 μm.

[0079] In order to obtain the described additive components, weigh the BaCO 3 , CaCO 3 and TiO 2 , so that the molar ratio was 9:1:10, and then they were mixed together using a ball mill, followed by heat treatment at 1,000° C., thereby forming Ba—Ti—Si—O crystal oxide. The crystallinity of these oxides was confirmed using XRD. In addition, the average diameter of crystal grains was 0.15 μm.

[0080] Then, weigh by volume (Ba 0.93 Ca 0.07 )TiO 3 and Ba-Ti-Si-O crystal oxide so that the weight ratio is 98:2 as shown in Table 1, and then use a ball mill to mix them together, thereby forming the dielectric compound according ...

Embodiment 1-2

[0082] According to the same method described in the above embodiment 1-1, after obtaining (Ba 0.93 Ca 0.07 )TiO 3 and Ba-Ti-Si-O crystal oxide, weigh by weight (Ba 0.93 Ca 0.07 )TiO 3 and Ba-Ti-Si-O crystal oxide, so that the weight ratio is 95:5 as shown in Table 1, and then use a ball mill to mix them together, thus forming the dielectric material according to Example 1-2 Powdered raw materials for ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com