Magnetic memory and its drive method, and magnetic memory apparatus using same

A magnetic storage and driving method technology, applied in the field of magnetic storage devices, can solve the problems of impedance rise, magnetization reversal magnetic field recording current increase, recording errors, etc., to suppress refinement, realize magnetization reversal, and smooth magnetization reversal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

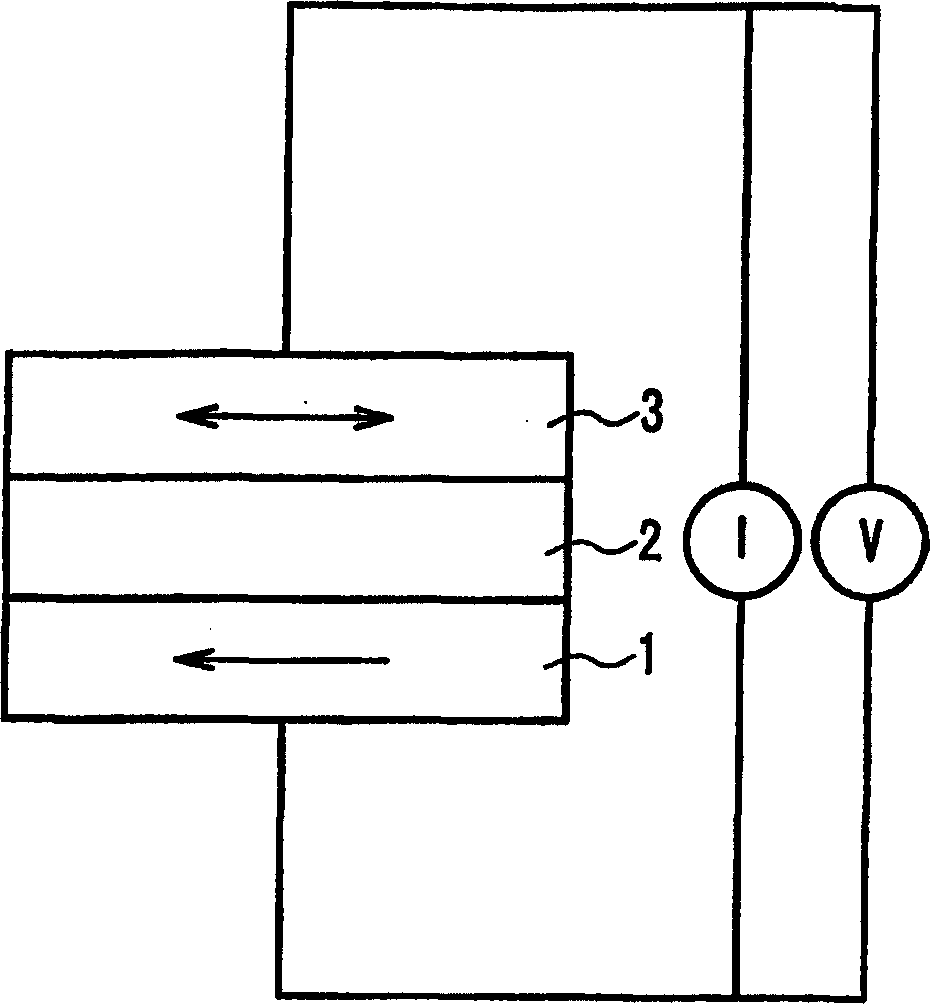

[0138] As shown in FIG. 3 , on a CMOS substrate, an integrated memory is fabricated using a magnetic memory composed of three stages of magnetoresistive elements. The integrated memory is sealed into a ceramic package, and a NiFe film with a thickness of 100 μm is plated on the entire package as a magnetic shield.

[0139] and Figure 11 The same as shown, the magnetic memories are arranged in a matrix shape, and every other storage column is configured with magnetic memories R1, R2, R3...( Figure 24 ). These magnetic memories also consist of 3-segment magnetoresistive elements. The magnetic memory is arranged in a manner of 256×256 (the total number of magnetoresistive elements is 256×256×3). There are 256 magnetic memories for comparison.

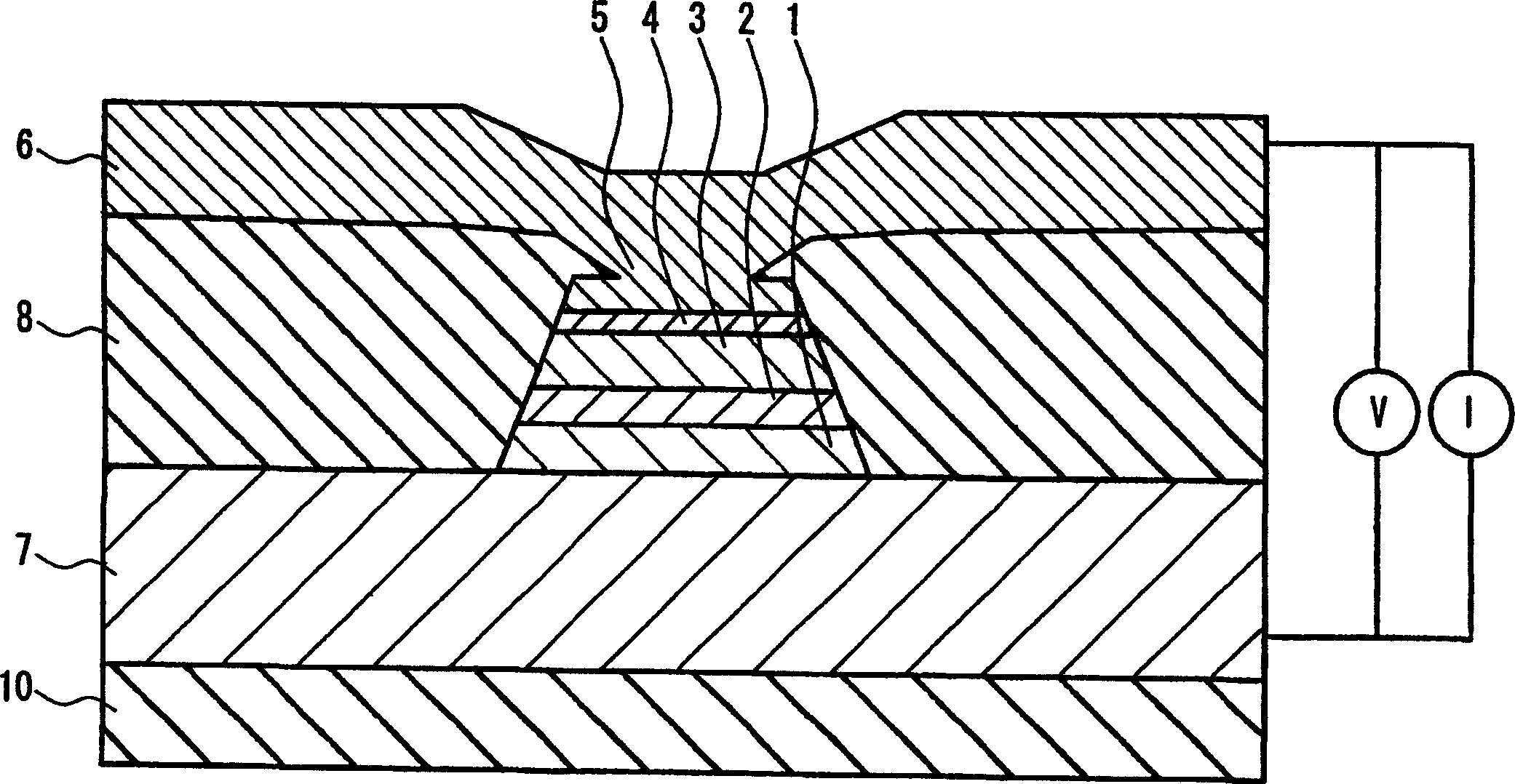

[0140] In each magnetic memory, a layered structure shown below was fabricated as a first-stage magnetic memory element.

[0141] Lower electrode / Ta(3) / PtMn(20) / CoFe(3) / Ru(0.9) / CoFe(3) / AlO(1.0) / NiFe(2) / AlO(1.0) / CoFe(3) / Ru( 0.9) / CoF...

Embodiment 2

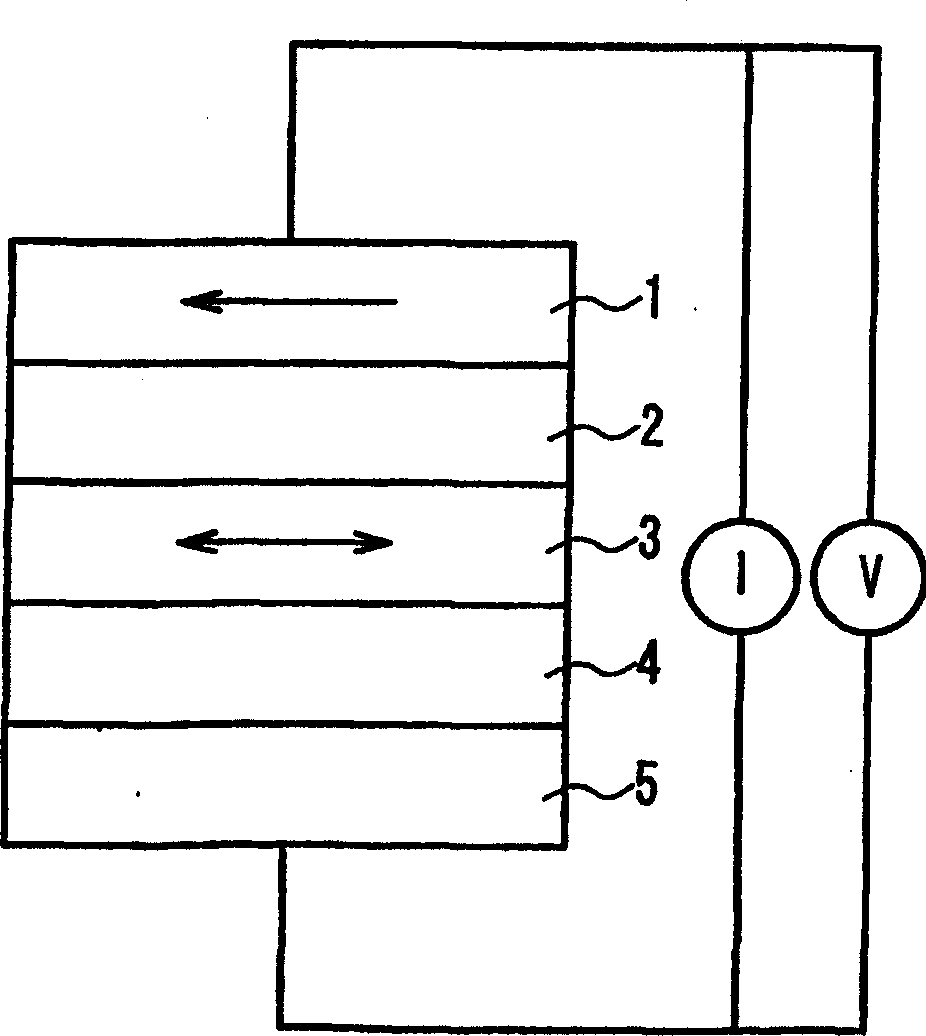

[0157] On a CMOS substrate, the pass will consist of a Figure 7 The magnetic memory composed of the magnetoresistive elements of the two memory layers 3 and 73 shown is arranged in a matrix to form an integrated memory. The same magnetic shielding as in Embodiment 1 is performed on the integrated memory. but, Figure 7 In the layers shown, the offset tunnel layers 4, 74 at both ends are omitted.

[0158] The arrangement of magnetic memory is identical with embodiment 1 ( Figure 24 ). In this integrated memory, the total number of memories is 256×256×2. This integrated memory is regarded as one frame, and a total of eight frames of MRAM are produced.

[0159] The film structure of the magnetoresistive element is as follows: lower electrode / Ta(3) / NiFeCr(4) / NiFe(2) / AlO(1.0) / CoFe(3) / Ru(0.8) / CoFe(3) / PtMn(20) / CoFe(3) / Ru(0.8) / CoFe(3) / AlO(1.06) / NiFe(2) / NiFeCr(4) / Ta(3) / upper electrode.

[0160] In this device, the tunnel layer and the memory layer are formed of AlO and NiFe, ...

Embodiment 3

[0169] On a glass substrate, an integrated memory was fabricated using a magnetic memory composed of three segments of magnetoresistive elements as shown in FIG. 9 . The same magnetic shielding as in Embodiment 1 is applied to the integrated memory.

[0170] Magnetic memory according to Figure 24 Arranged as shown. The magnetic memories are arranged in the form of 256×256 (the total number of magnetoresistive elements is 256×256×3), and these magnetic memory groups are regarded as one frame, and a total of 8 frames of MRAM are produced.

[0171] Among the three elements, the film structure of the magnetoresistive element is as follows:

[0172] Lower electrode / Ta(3) / PtMn(20) / CoFe(3) / Ru(0.9) / CoFe(3) / AlO(1.0) / Fe(2) / AlO(1.3) / Ta(3) / Upper electrode .

[0173] In this device, the tunnel layer and the memory layer are formed of AlO and Fe, respectively. AlO in contact with Ta is a bias tunneling layer.

[0174] This multilayer film is heat-treated in the same manner as in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com