Recovery of tin from waste liquid of tin and lead

A waste liquid and tin-lead technology, applied in the field of tin recycling, can solve the problems of waste of limited resources, secondary environmental pollution, heavy metal transfer, etc., achieve significant economic benefits, and solve the effect of secondary pollution of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

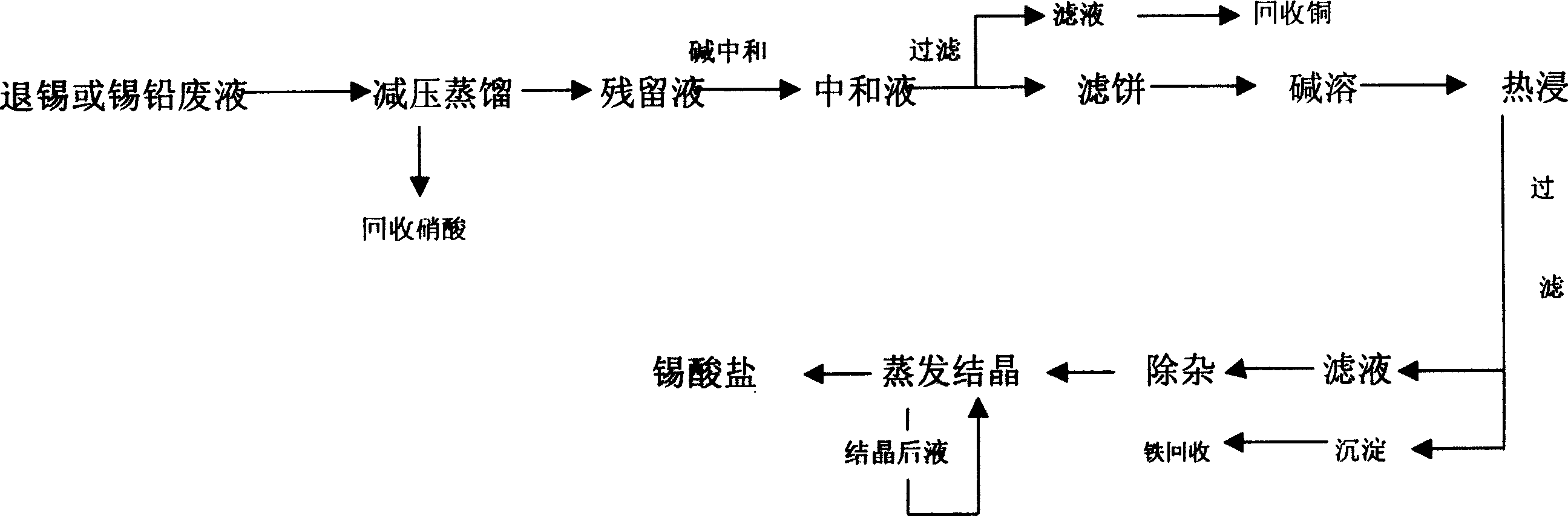

[0044] A kind of implementation process step of the present invention is:

[0045] (1) Carry out vacuum distillation on the printed circuit board tin stripping waste liquid to two-thirds of the volume of the original liquid, the temperature is 75°C, and the pressure is 0.5×1.03×10 5 Pa;

[0046] (2) Add NaOH to neutralize the waste liquid after distillation, and control the pH value of the neutralized solution to 6-8;

[0047] (3) filter the above-mentioned neutralization waste liquid in a conventional manner to obtain a filter cake;

[0048] (4) NaOH is added to the obtained filter cake and heated to 120°C for alkali dissolution until completely dissolved;

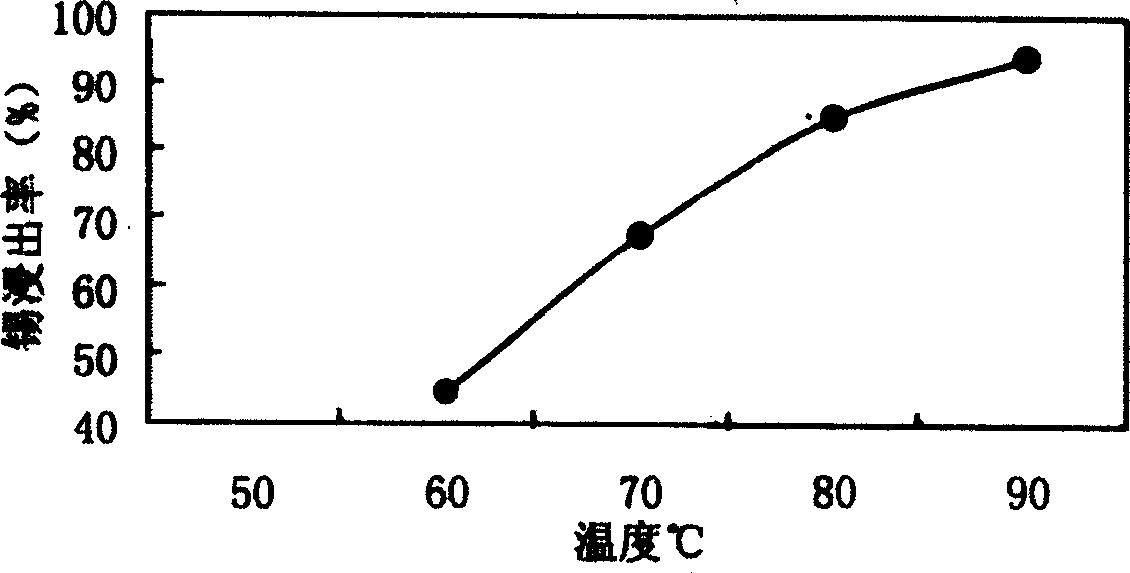

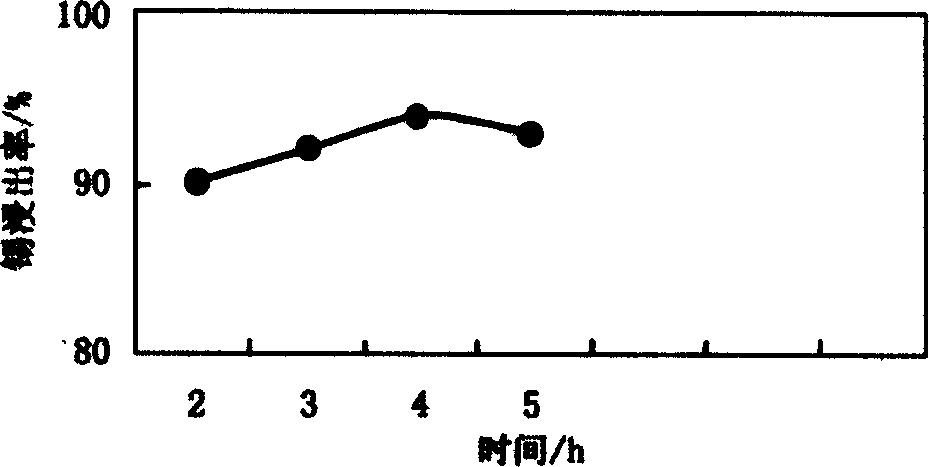

[0049] (5) Hot-soak the alkali solution for 4 hours at a temperature of 95° C., an alkali (NaOH) concentration of 200 g / L, and a liquid-solid ratio of 6 parts by weight of water to the filter cake;

[0050] (6) Routine filtration of the hot dipping solution, adding a corresponding amount of Na to the filtrate 2 S remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com