Pressure controlled constant tempeature crystal oscillator

A technology of oven controlled crystal oscillation and crystal oscillator, which is applied in power oscillators, temperature control by electric means, electrical components, etc. , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

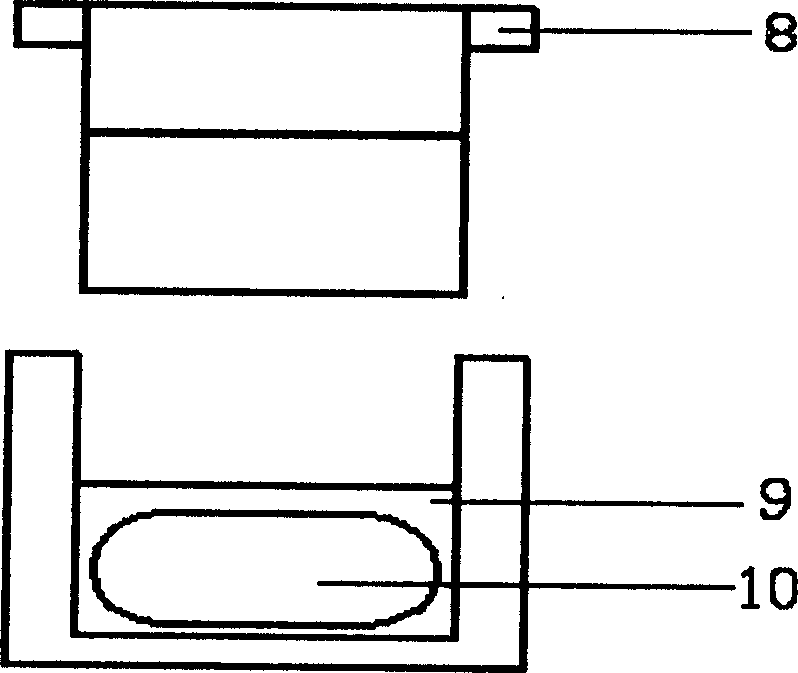

[0017] In order to improve the temperature control accuracy and comply with the development trend of miniaturization of electronic devices, it is necessary to change the traditional way of using discrete components, choose a new temperature control method and carefully design the structure of the constant temperature bath.

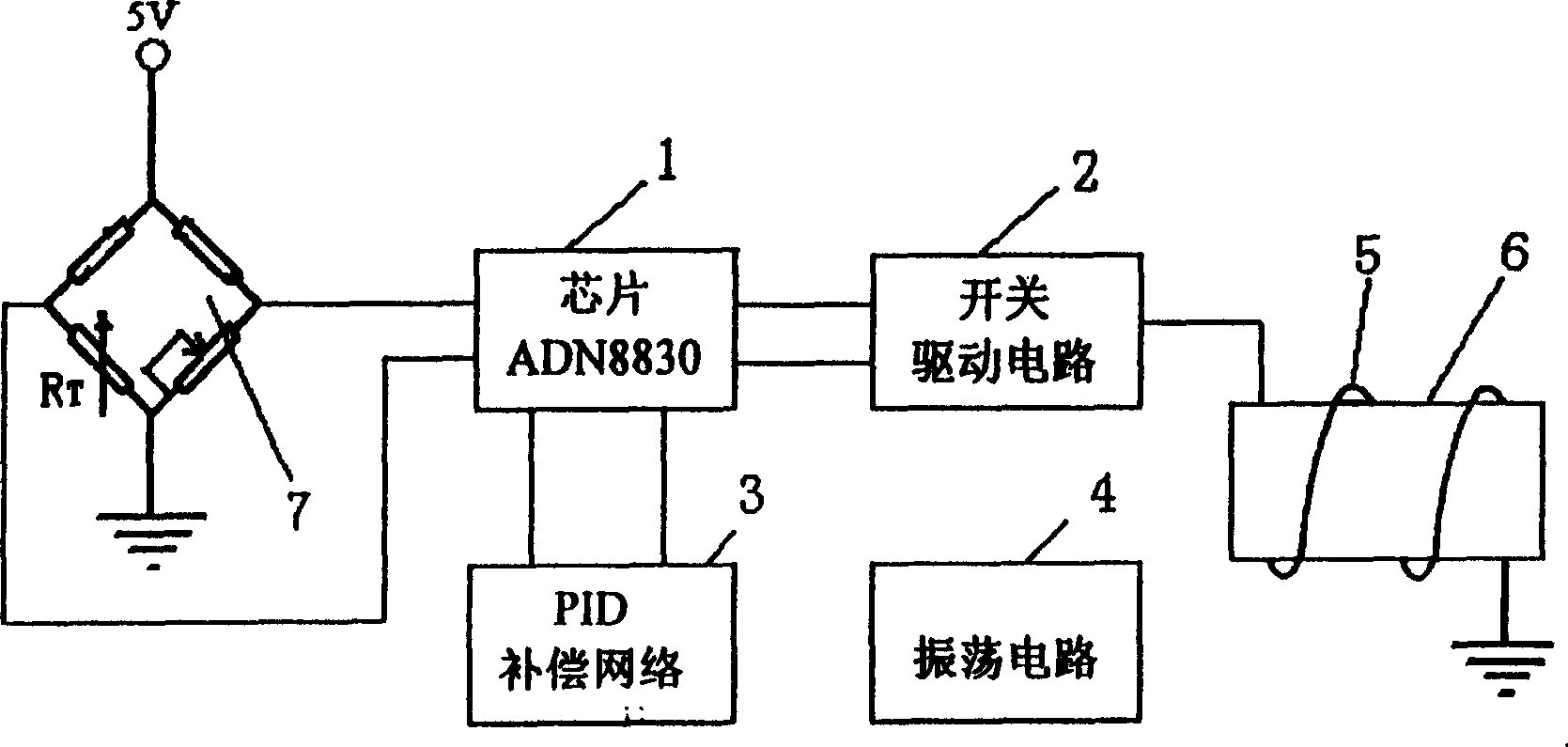

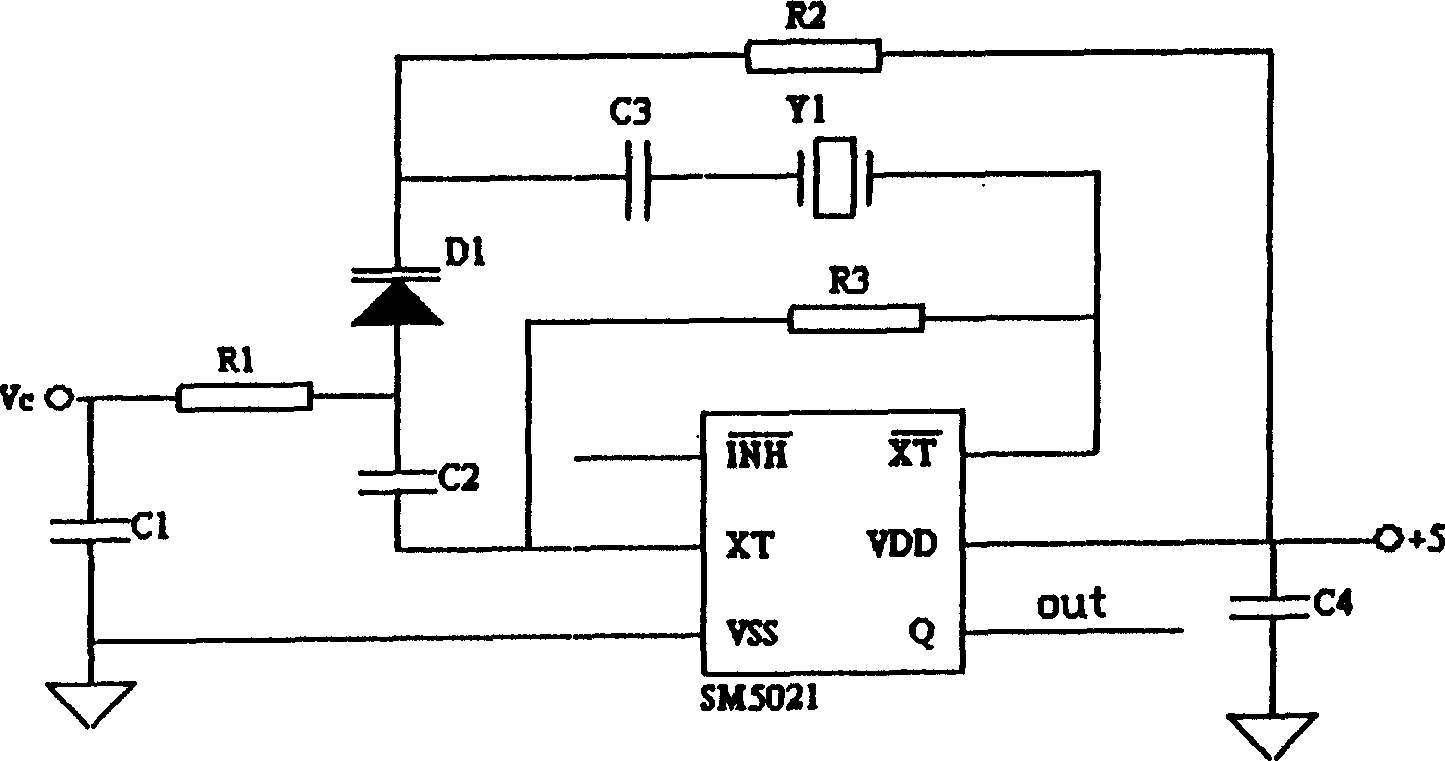

[0018] Depend on figure 1 As shown, the present invention includes: a temperature control chip ADN88301, a switch drive circuit 2, a PID compensation circuit 3, an oscillation circuit 4, a heating element 5, a constant temperature bath 6, and a temperature sensing circuit 7. The above-mentioned heating element 5 can be a resistance wire or a positive temperature coefficient thermistor PTC. In the drawings, the heating element 5 is an example of a resistance wire, and the temperature sensing circuit 7 is an example of a thermistor bridge.

[0019] The temperature control chip ADN88301 is connected to the thermistor bridge, and outputs a square wave with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com