Anti-dazzling membrane

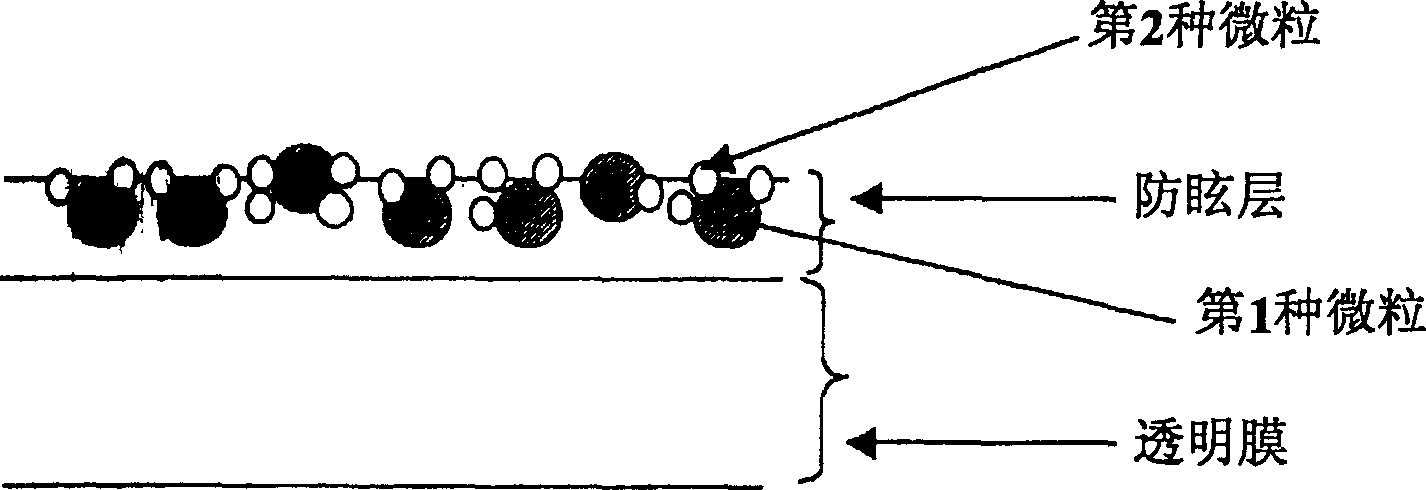

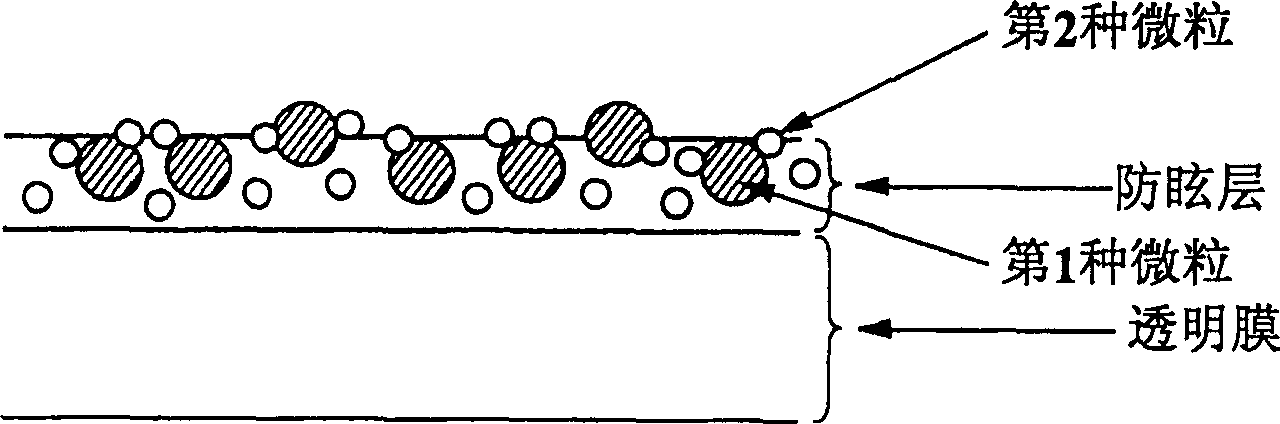

A technology of anti-glare film and anti-glare layer, which is applied in TV, color TV, applications, etc., and can solve the problems of black display image quality degradation, white screen, screen flickering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] [paint preparation]

[0038] 3.0 g of MX300 (polyacrylic resin particles, average particle diameter 3.0 μm, manufactured by Soken Chemical Co., Ltd.), PL-1 (40% silica fine particle dispersion in toluene, average particle diameter 0.01 μm, manufactured by Fuso Chemical Co., Ltd. ) Co., Ltd.) 7.5 g and 20.0 g of toluene were mixed and stirred well. To this solution, 41.7 g of Viimset 500 (acrylic ionizing radiation-curable resin, manufactured by Arakawa Chemical Co., Ltd.) and 2.3 g of Darokyua 1173 (photopolymerization initiator, manufactured by Ciba Specialty Chemical Co., Ltd.) were added. , then add 23.0 g of methyl ethyl ketone (MEK) and 2.5 g of ethylene glycol monobutyl ether (butyl cellosolve), and add 0.5 g of BYK320 (manufactured by BYK Chemical Co., Ltd.) as a leveling agent, and fully Stir to prepare a coating.

[0039] [Anti-glare film production]

[0040] On FTUV80UZ (triacetyl cellulose film, produced by Fuji Photo Film Co., Ltd.), the coating of the ab...

Embodiment 2

[0042] [paint preparation]

[0043] MX300, 3.0 g, and 7.5 g of PL-3 (40% dispersion of silica fine particles in toluene, manufactured by Fuso Chemical Co., Ltd., average particle size: 0.03 μm) and 20.0 g of toluene were mixed and stirred thoroughly. To this solution, add Viimset 500, 41.7 g, Daroquia 1173, 2.3 g, MEK, 23.0 g, butyl cellosolve 2.5 g, and BYK 320, 0.5 g, and stir well to prepare a paint.

[0044] [Anti-glare film production]

[0045] Apply the above paint on the FTUV80UZ through a Meyer rod #6, and after drying at 80°C for 1 minute, use a high-pressure mercury lamp to irradiate 350mJ / cm in a nitrogen environment 2 curing by ultraviolet light. The thickness of the obtained coating film was 4.2 μm.

Embodiment 3

[0047] [paint preparation]

[0048] Mix 1.8 g of MX150 (polyacrylic resin microparticles, manufactured by Soken Chemical Co., Ltd., average particle diameter: 1.5 μm), 3.0 g of PL-1, and 33.2 g of toluene, and stir well. To this solution, 25.6 g of Viimset 500 and 1.4 g of Daroquia 1173 were added, 31.5 g of MEK and 3.5 g of butyl cellosolve were added, and 0.5 g of BYK 320 was added, and stirred well to prepare a paint.

[0049] [Anti-glare film production]

[0050] Apply the above paint on the FTUV80UZ through a Meyer rod #6, and after drying at 80°C for 1 minute, use a high-pressure mercury lamp to irradiate 350mJ / cm in a nitrogen environment 2 curing by ultraviolet light. The thickness of the obtained coating film was 2.7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com