Rectangular vacuum gate valve

A vacuum insert, rectangular technology, applied in the direction of sliding valves, valve devices, engine components, etc., can solve the problems of unsuitable valves with circular ports, etc., and achieve the effect of high passing rate, simple structure and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

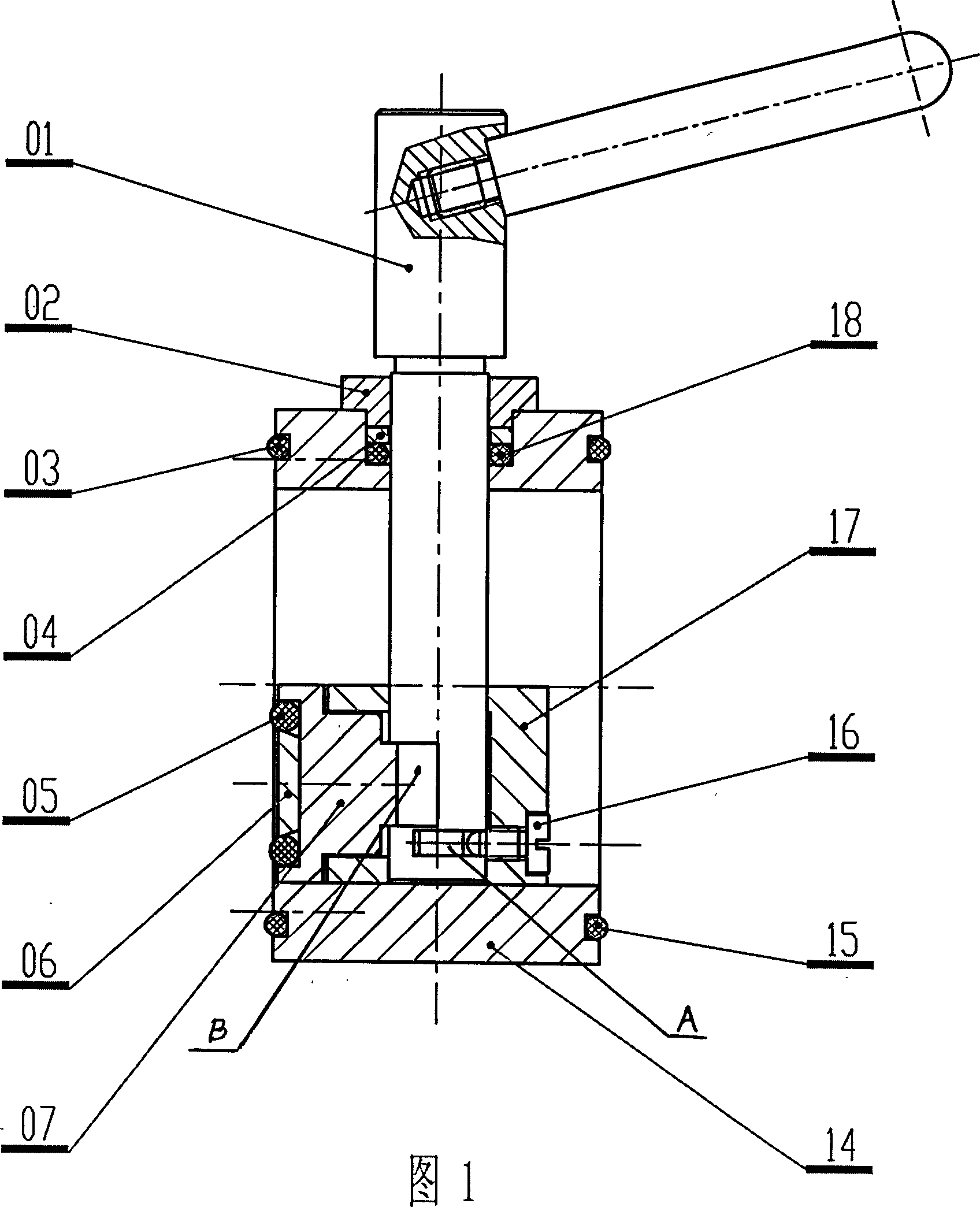

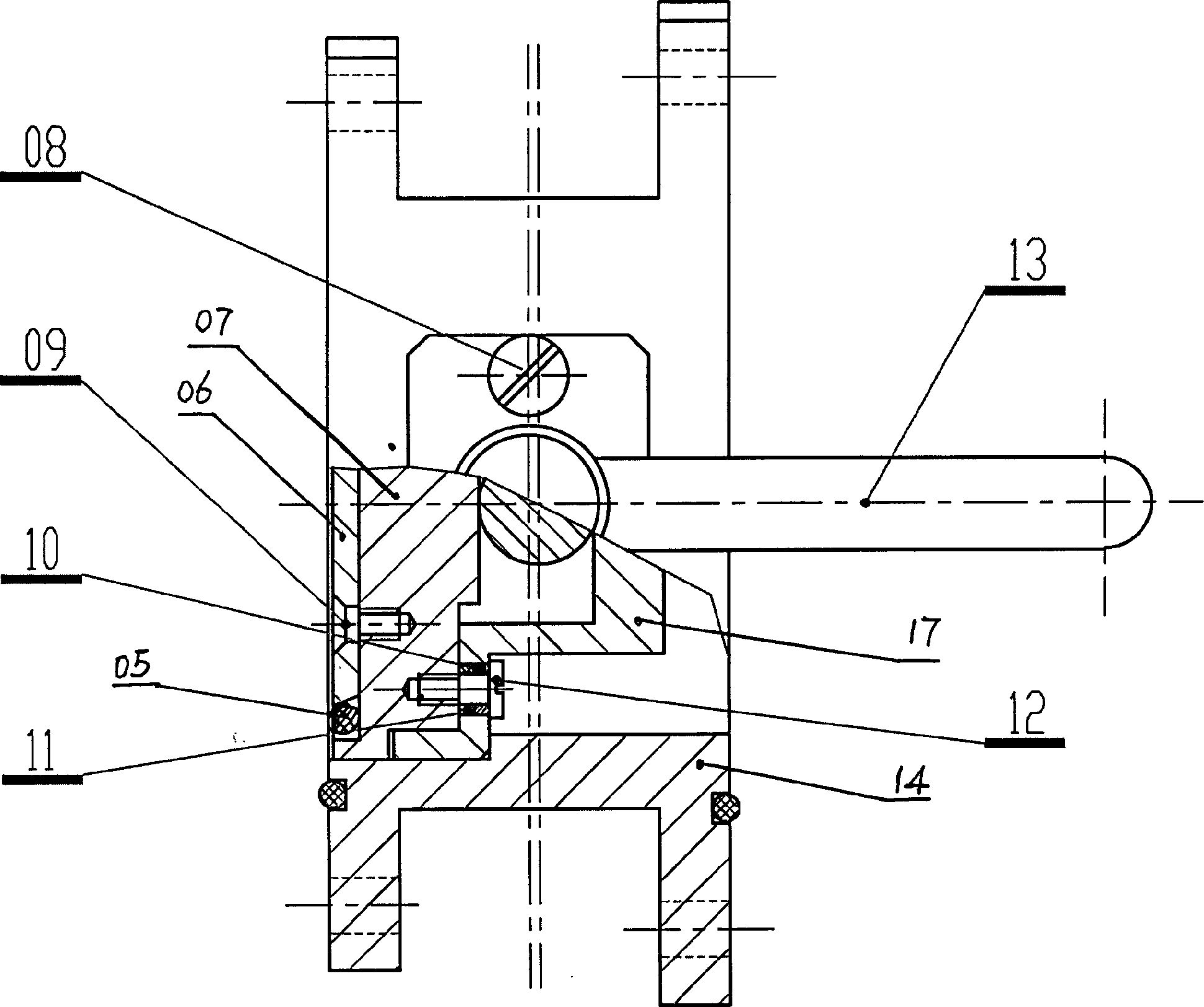

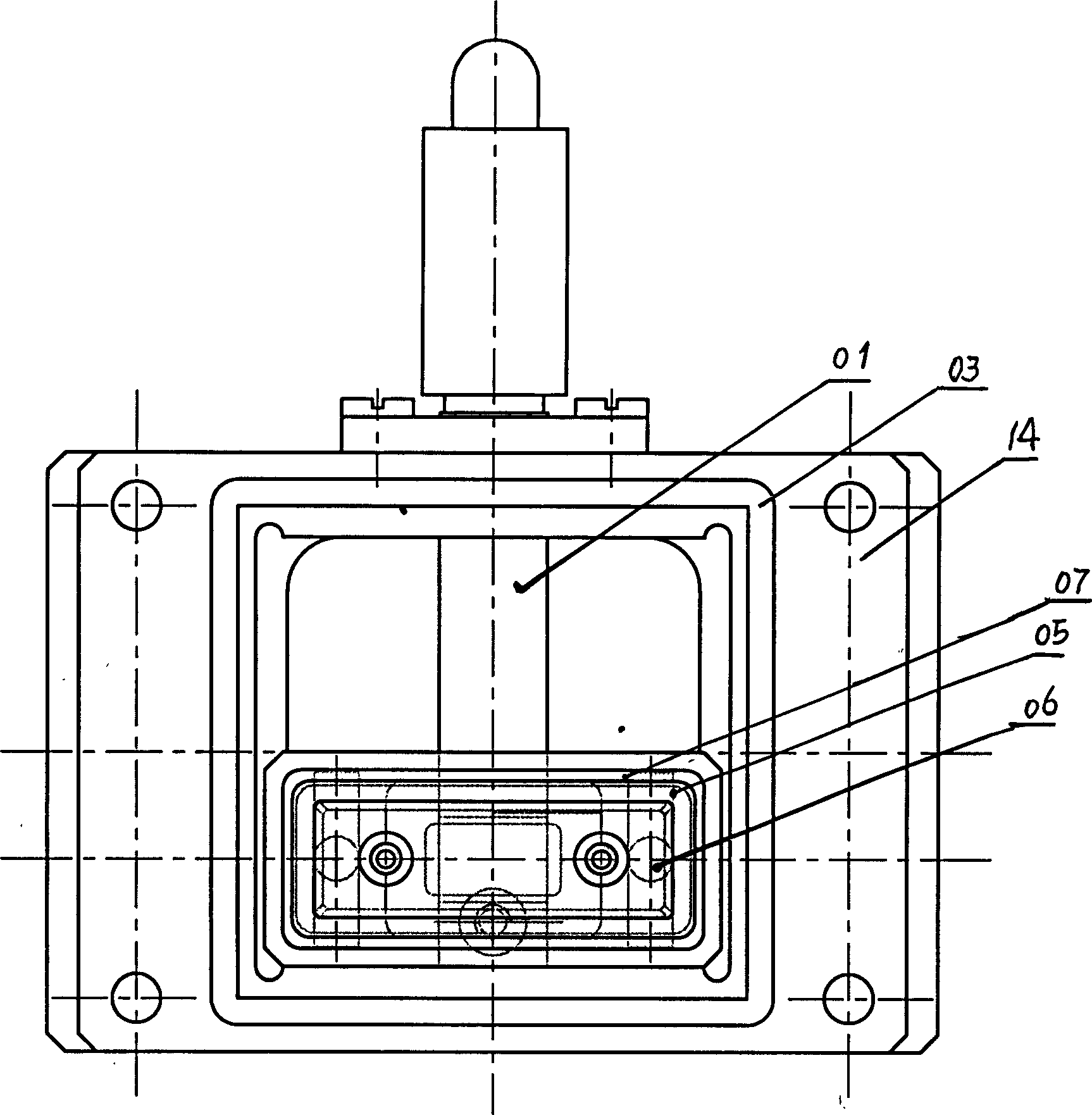

[0010] According to the structural drawings 1 to 3, the handle (13) is installed on the valve shaft (1); Installed on the valve body shell (14) to ensure that the valve shaft (1) does not leak air when it moves up and down and rotates; the pressing piece (6) is fixed on the valve plate (7) by thin nails (9), and the fluororubber sealing ring (5) is fixed on the valve plate (7) by the pressing piece (6); the lower part of the valve shaft (1) passes through the valve body (17), and the set screw (16) fixes the valve body (17) on the valve shaft (1 ); while the screw (12), spring (10) and washer (11) connect the valve body (17) and the valve plate (7), when the valve shaft (1) is turned, due to the There is a semicircular eccentric groove (B) to make displacement and reset between the valve body (17) and the valve plate (7) under the joint action of the spring (10).

[0011] When closing the valve, press the handle (13) to drive the valve stem (1), valve body (17), valve plate (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com