High efficiency low temperature heat transfer element based on natural circulation precooling process

A technology of natural circulation and heat transfer elements, which is applied in the direction of refrigerators, indirect heat exchangers, refrigeration and liquefaction, etc., and can solve the problems of limiting the cold transfer of refrigerators and the small diameter of copper rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

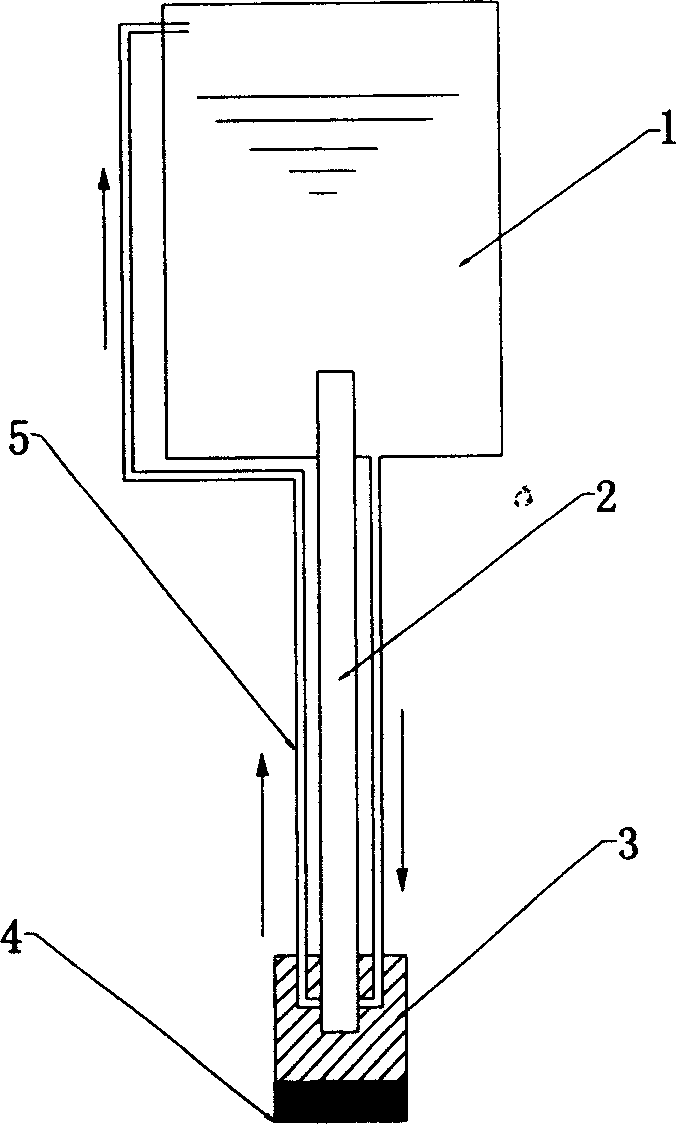

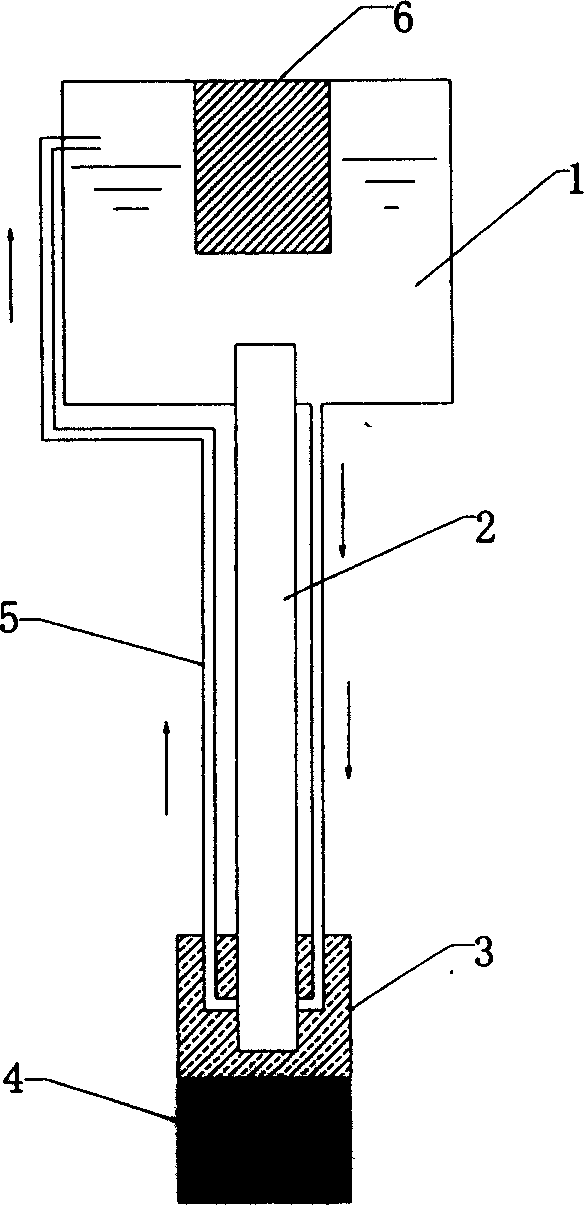

[0009] The high-efficiency low-temperature heat transfer element based on the natural circulation pre-cooling process has a low-temperature liquid storage tank 1 and is connected with a low-temperature heat pipe 2 and a cold head 3 in sequence. The top of the liquid storage tank is connected, and the cooled object 4 is arranged on the cold head. The low-temperature liquid storage tank is provided with a low-temperature refrigerator 6 .

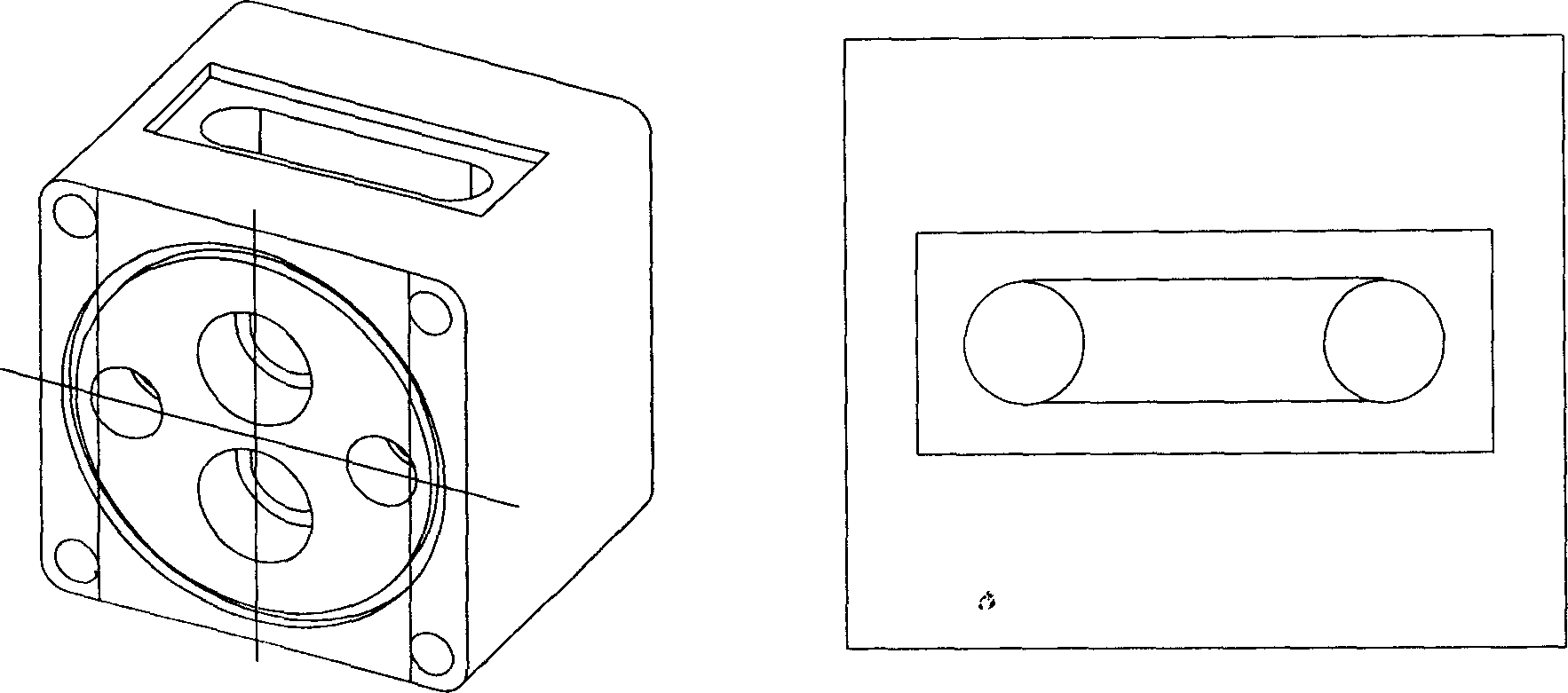

[0010] The material of the above-mentioned low-temperature heat pipe is stainless steel, copper, aluminum alloy, and its shape is circular or rectangular. The material of the natural circulation pre-cooling circuit is stainless steel, copper, aluminum alloy; the shape of the natural circulation pre-cooling circuit is round or square. The material of the cold head is copper or oxygen-free copper; the shape of the cooling medium storage tank is a cylindrical cavity or a rectangular cavity. Cryogenic liquids are: liquid helium, liquid hydrogen,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com