Portable temperature control conical shaped plate shearing pool

A shear cell, portable technology, applied in the field of portable temperature-controlled cone-plate shear cell, can solve the problems of single shear cell and detection system, and difficulty in installing synchrotron radiation windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

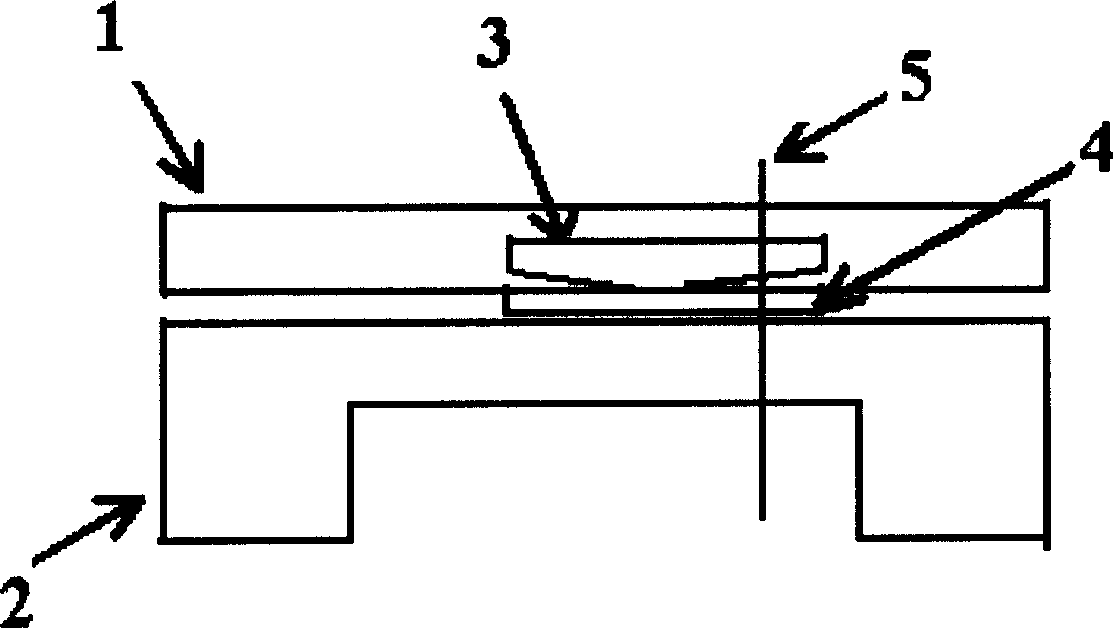

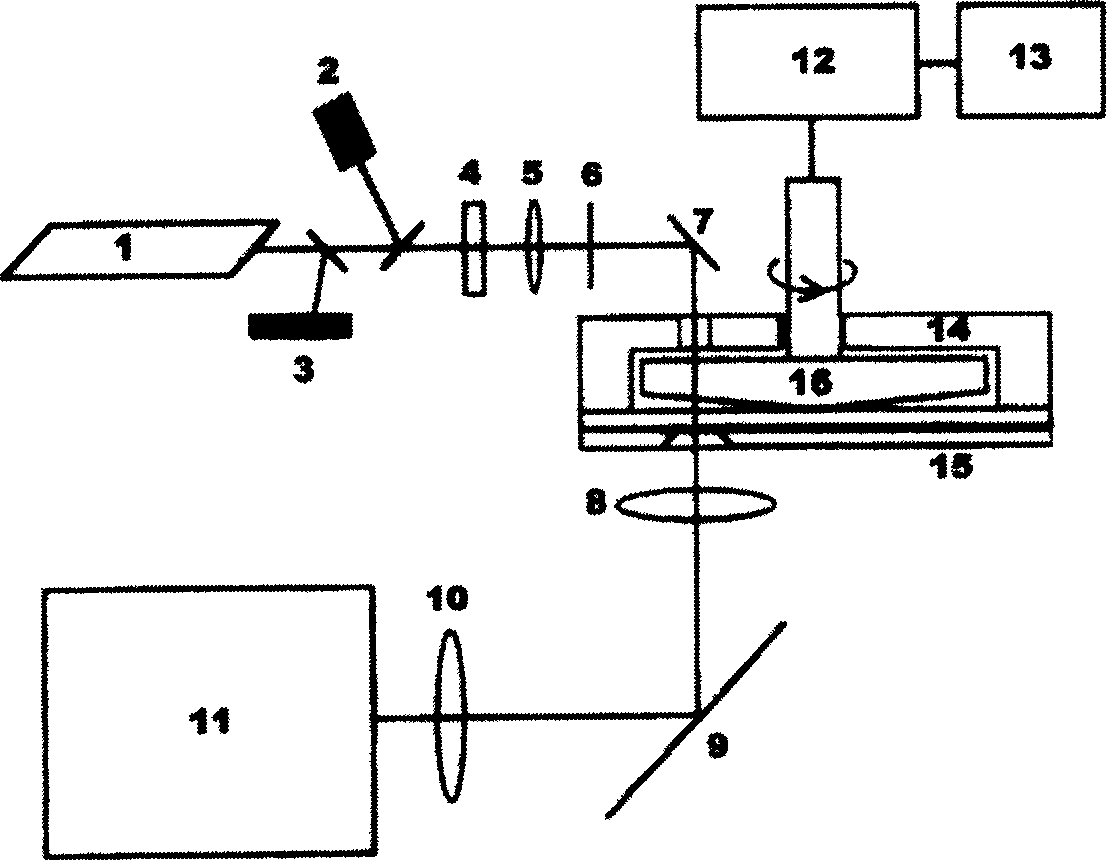

[0010] Embodiments of the present invention are described as follows in conjunction with accompanying drawing 1 and 2:

[0011] Figure 1 is a cross-sectional view of a shear cell,

[0012] Figure 2 is a schematic diagram of the working principle of the shear cell and the laser system.

[0013] The shear cell adopts the geometry of quartz cone and plate, and the relative rotation occurs under the control of the micro-step motor, so as to produce a visible shear field with a strictly controllable shear rate and other measures. In the actual use process, the following systems can be used to detect the properties of polymers under the action of shear field:

[0014] Laser Light Scattering System: Using He-Ne laser as the light source, the emitted laser light enters the shearing cell through optical elements such as attenuation plates, and the scattered light is converged to the CCD through two lenses, and Fourier images are recorded.

[0015] Phase-contrast microscope system: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com