Abrasive diamond composite and method of making thereof

A composite material and diamond technology, applied in the field of abrasive composite materials, can solve problems such as diamond degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

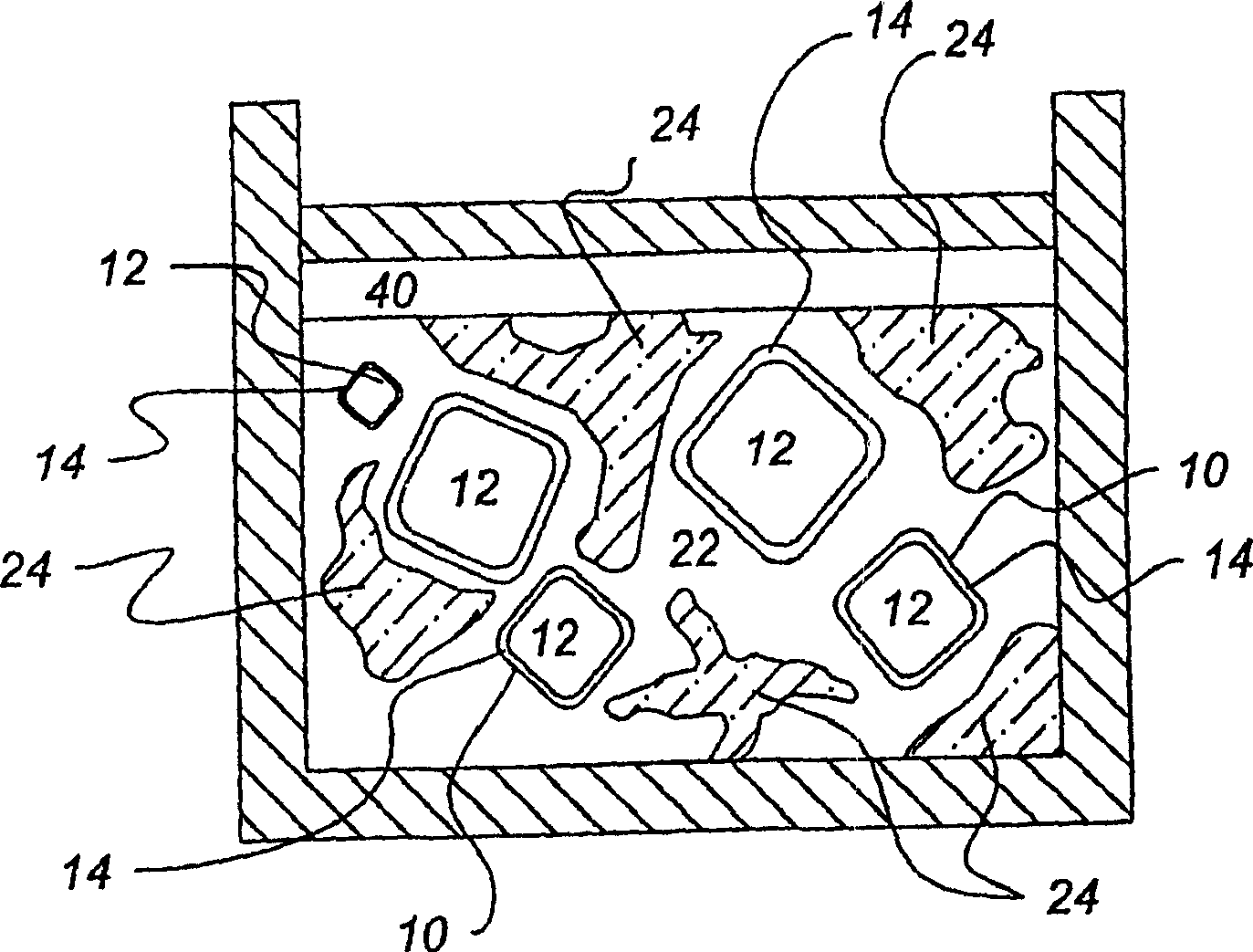

[0041] 0.3 g of commercial uncoated high-grade saw diamond crystals were mixed with 6 g of technical grade acyl iron powder and placed in an alumina boat. The boat was then placed in a furnace and heated to 850°C for a period of 1 hour in a hydrogen atmosphere. After taking it out from the furnace and cooling it, pass it successively in aqua regia, that is, 1:1 HF / HNO 3 Neutralize 9:1 H 2 SO 4 / HNO 3 Boil in medium to recover diamond from a part of free sintering.

[0042] The recovered diamonds were then evaluated by optical microscopy to estimate the extent of chemical attack. The recovered uncoated diamonds are indicated in Figure 5 middle. As can be seen in the photographs, a significant degree of corrosion in the iron matrix was observed for the uncoated diamond.

[0043] By measuring the difference in the apparent hardness of the diamond tip in the matrix versus the hardness of the matrix itself, the relative bond and retention of the diamond to the matrix is e...

Embodiment 2

[0046] Commercially available diamond crystals for premium saws were coated with tungsten carbide (WC). The thickness of the WC coating is about 1.3 μm. 0.3g of coated diamond was then mixed with 6g of technical grade carbonyl iron powder and placed in an aluminum boat. The boat was then placed in a furnace and heated to 850°C for a period of 1 hour in a hydrogen atmosphere. After taking it out from the furnace and cooling it, pass it successively in aqua regia, that is, 1:1 HF / HNO 3 Neutralize 9:1 H 2 SO 4 / HNO 3 Boil in medium to recover diamond from part of freely sintered parts.

[0047] The recovered diamonds were then evaluated by optical microscopy to estimate the extent of chemical attack. The recovered coated diamonds are indicated in Image 6 middle. with uncoated diamond ( Figure 5 ) compared to the appearance of the diamond without WC coating was observed to be eroded by the iron matrix, indicating that the presence of the WC coating on the diamond improv...

Embodiment 3

[0050] Commercially available diamond crystals for high-grade saws were coated with silicon carbide (SiC). The thickness of the SiC coating is about 5 μm. 0.3g of coated diamond was then mixed with 6g of technical grade carbonyl iron powder and placed in an aluminum boat. The boat was then placed in a furnace and heated to 850°C in a hydrogen atmosphere for a period of 1 hour. After taking it out from the furnace and cooling it, pass it successively in aqua regia, that is, 1:1 HF / HNO 3 Neutralize 9:1 H 2 SO 4 / HNO 3 Boil in medium to recover diamond from part of freely sintered parts.

[0051] The recovered diamonds were then evaluated by optical microscopy to estimate the extent of chemical attack. The recovered coated diamonds are indicated in Figure 7 middle. with uncoated diamond ( Figure 5 ) compared to the appearance of the diamond without SiC coating was observed to be eroded by the iron matrix, indicating that the presence of the SiC coating on the diamond i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com