Soft measure for polyester product quality target and process operating optimization method

A technology of product quality and soft measurement, applied in interdisciplinary fields, can solve the problems of sensitive process operation conditions, loss of online guidance, large lag, etc., and achieve the effect of improving process operation level, stabilizing product quality, and optimizing production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

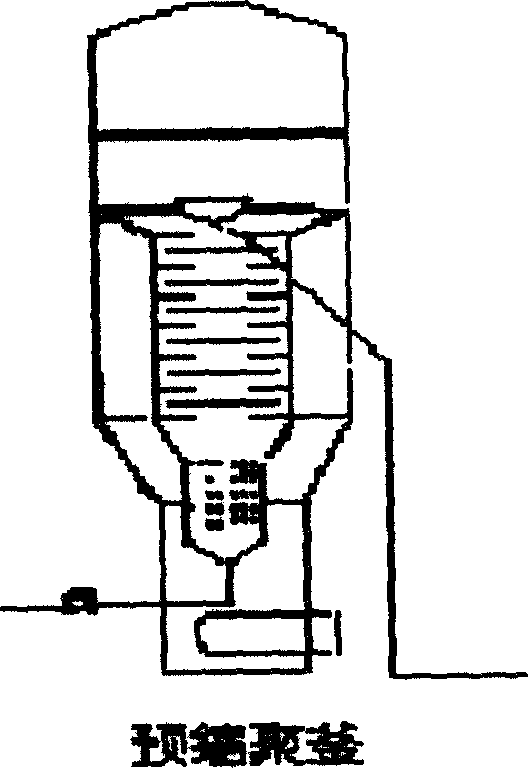

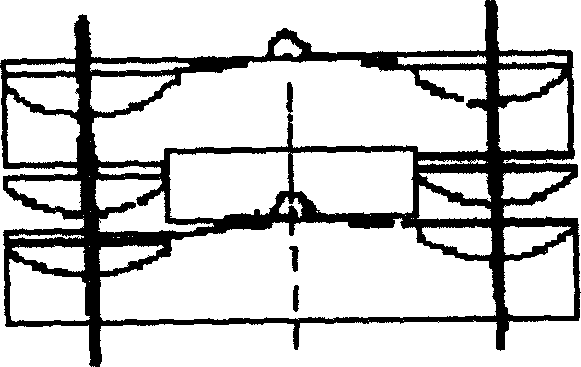

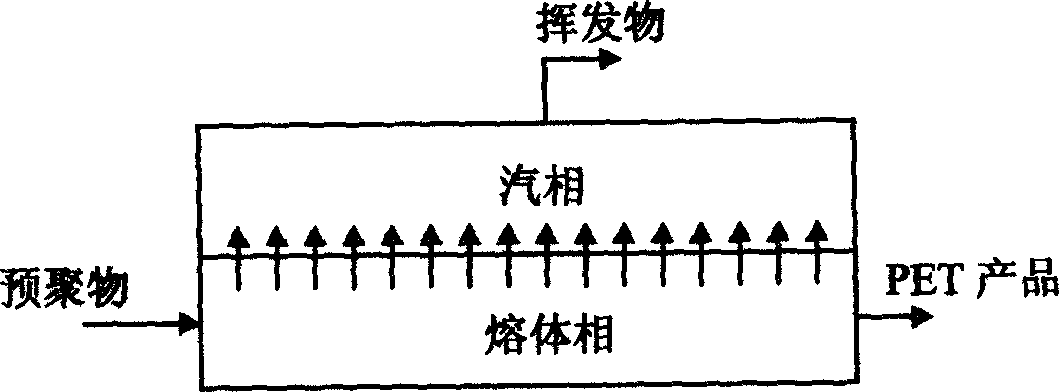

[0022] 1. Process model development

[0023] The application and development of process model technology and the improvement of automation level have reflected the high-tech connotation of the enterprise, and are also an important part of the core technology of modern industry, as well as the innovation and difficulty of the software system development. Process model development After in-depth analysis of the reactor structure, mass transfer and flow conditions, the model of the esterification, pre-condensation and final polycondensation reactors was established by combining the mechanism analysis and the actual measurement data for parameter identification. The developed models were studied by simulation. And parameter verification and online operation, the model accuracy meets the requirements of different control purposes and process analysis.

[0024] 1. Esterific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com