Industrial air cooling direct evaporation type heat pump clean central air conditioner

A central air-conditioning and industrial technology, applied in the direction of household heating, air-conditioning systems, applications, etc., can solve the problems of difficult quality control, ineffective energy consumption, and scattered stakeholders, and achieve simplified ceiling structure and practices, cleanliness protection, etc. The effect of increasing the degree of obstruction and reducing the scope of the polluted area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

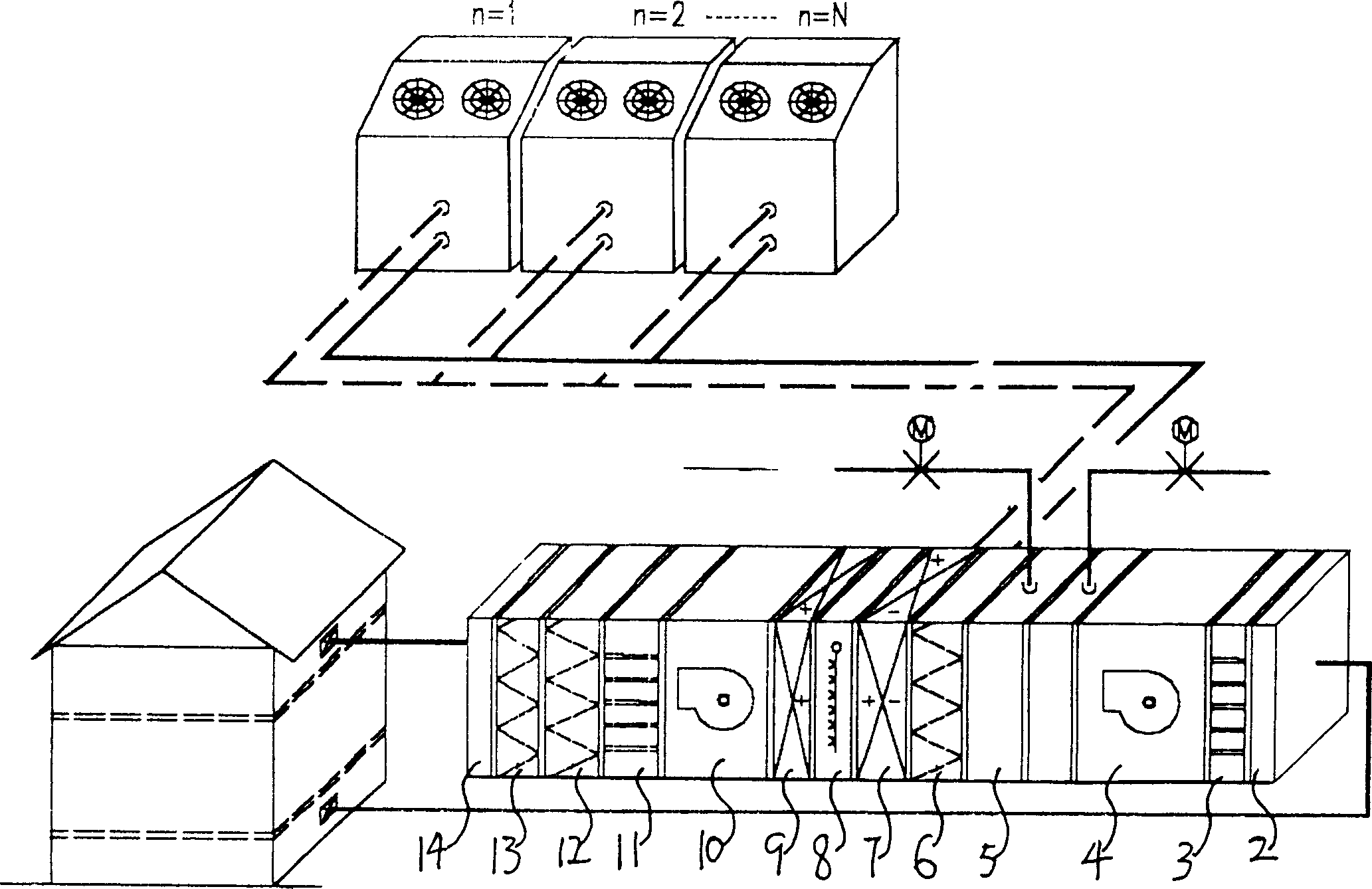

[0066] Refer to attached figure 1 , The industrial air-cooled direct-evaporation heat pump clean central air conditioner of the present invention includes an air-supply static pressure box 1 and a combined purification air treatment device connected to it through pipelines. The ducts include exhaust ducts and air supply ducts. The clean room is in the working room, the air supply plenum 1 is set above the clean room, and the combined clean air treatment device is set in the working room outside the clean room. The combined air purification treatment device includes return air electric airtight door 2, return air muffler section 3, indoor return fan 4, mixing pipe 5, primary filter section 6, surface cooling / heating section 7, humidification section 8, Electric auxiliary heating section 9, indoor air blower 10, air supply muffler end 11, medium-efficiency filter section 12, high-efficiency filter section 13, and air-supply electric airtight door 14.

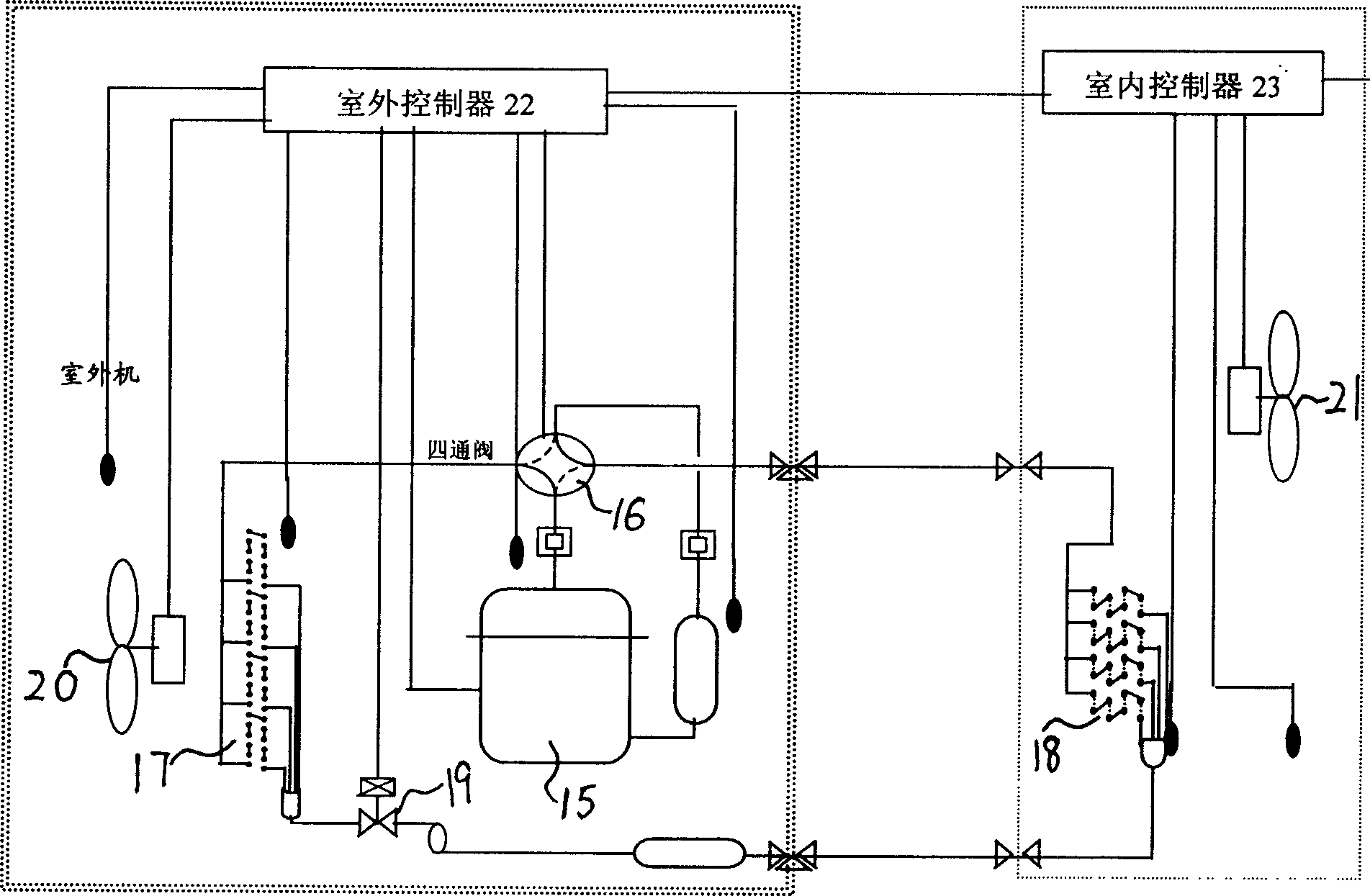

[0067] Refer to attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com