Optical lens protective device

A technology for optical lenses and protective devices, applied in optics, optical components, televisions, etc., can solve the problem of unusable optical lenses, and achieve the effect of reducing drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

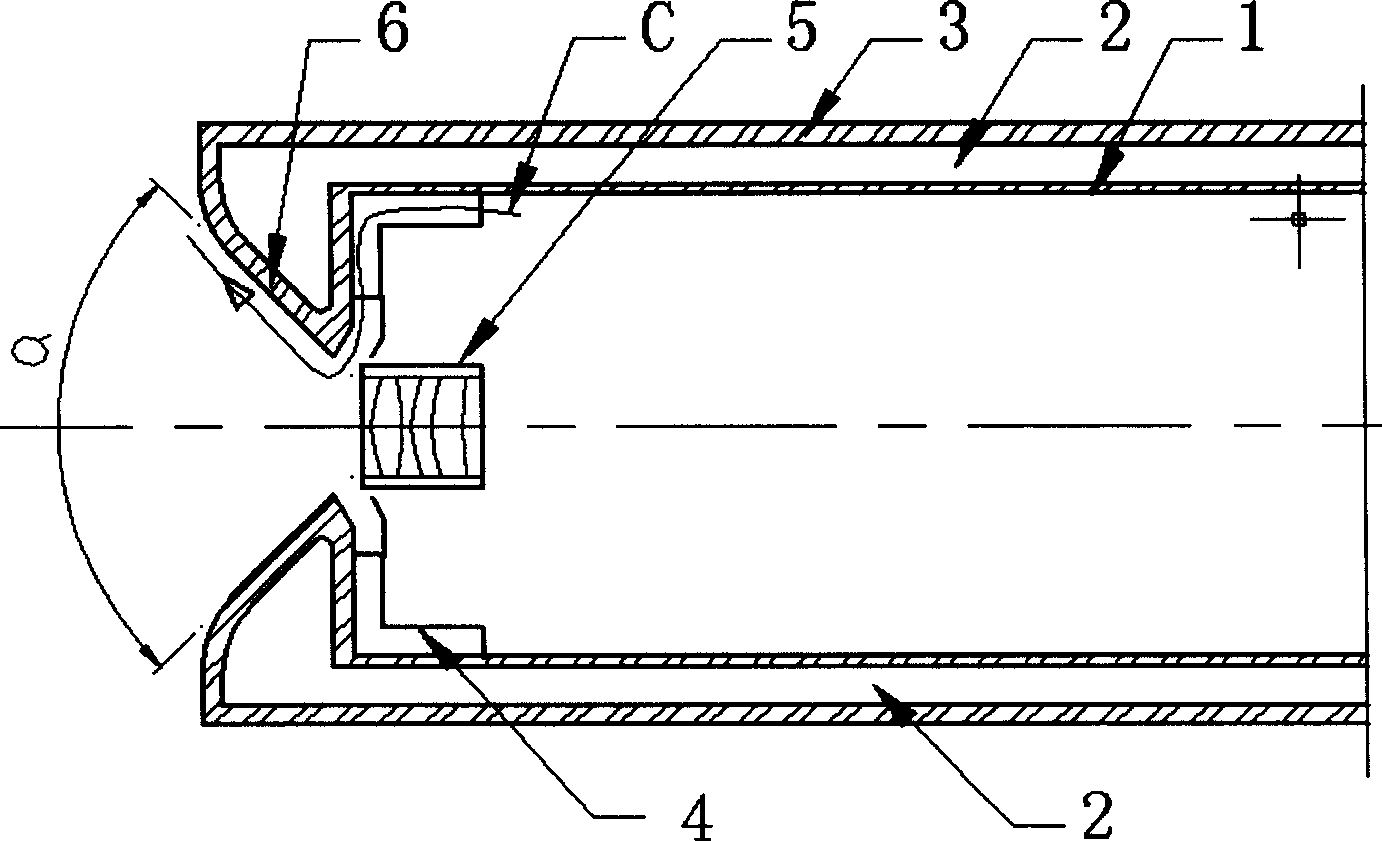

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

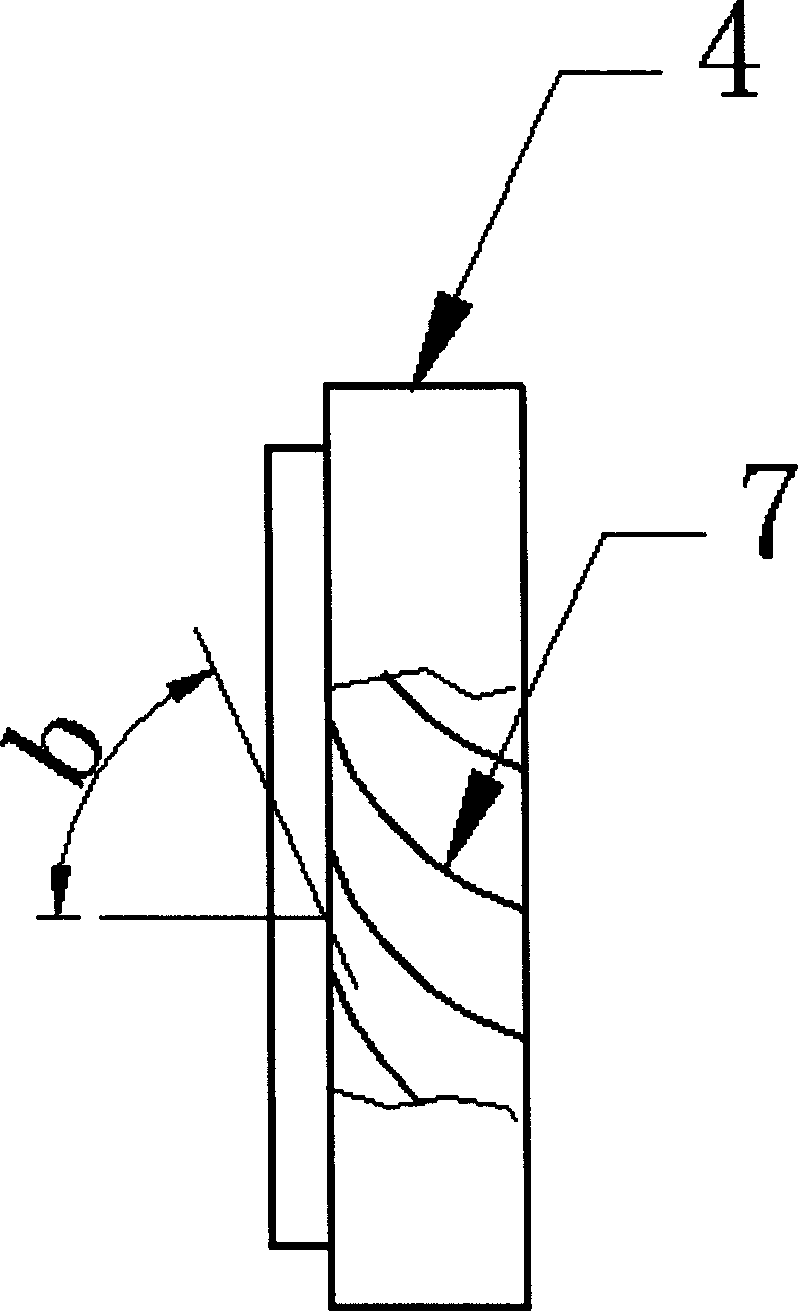

[0015] The inner cylinder 1 of the protective chamber is a stainless steel cylinder with an inner diameter of 80 mm and a thickness of 1 mm, the outer cylinder of the protective chamber 3 is a stainless steel cylinder with an outer diameter of 90 mm and a thickness of 2 mm, the front end cover 6 is a tapered stainless steel, and the diameter of the middle optical channel is 14 mm. The cone angle α is 90 degrees. The deflector 4 is a stainless steel ring with an outer diameter of 70 mm, an inner diameter of 30 mm, and a height of 5 mm. The number of deflectors is 8, and the angle b is 60 degrees. The optical lens 5 is a lens with a focal length of 4 millimeters, and the angle of view is 76 degrees.

[0016] The protective gas flowing into the cavity is pure nitrogen with a flow rate of 10 liters / minute, and the cooling water in the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com