Slotless asgchronous motor

A technology for asynchronous motors and magnetic poles, which is applied to the rotating parts of the magnetic circuit, the static parts of the magnetic circuit, and the manufacture of stator/rotor bodies, etc. It can solve the problems of low material utilization, insufficient efficiency, and low magnetic permeability, etc. Utilization, efficiency improvement, high magnetic permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

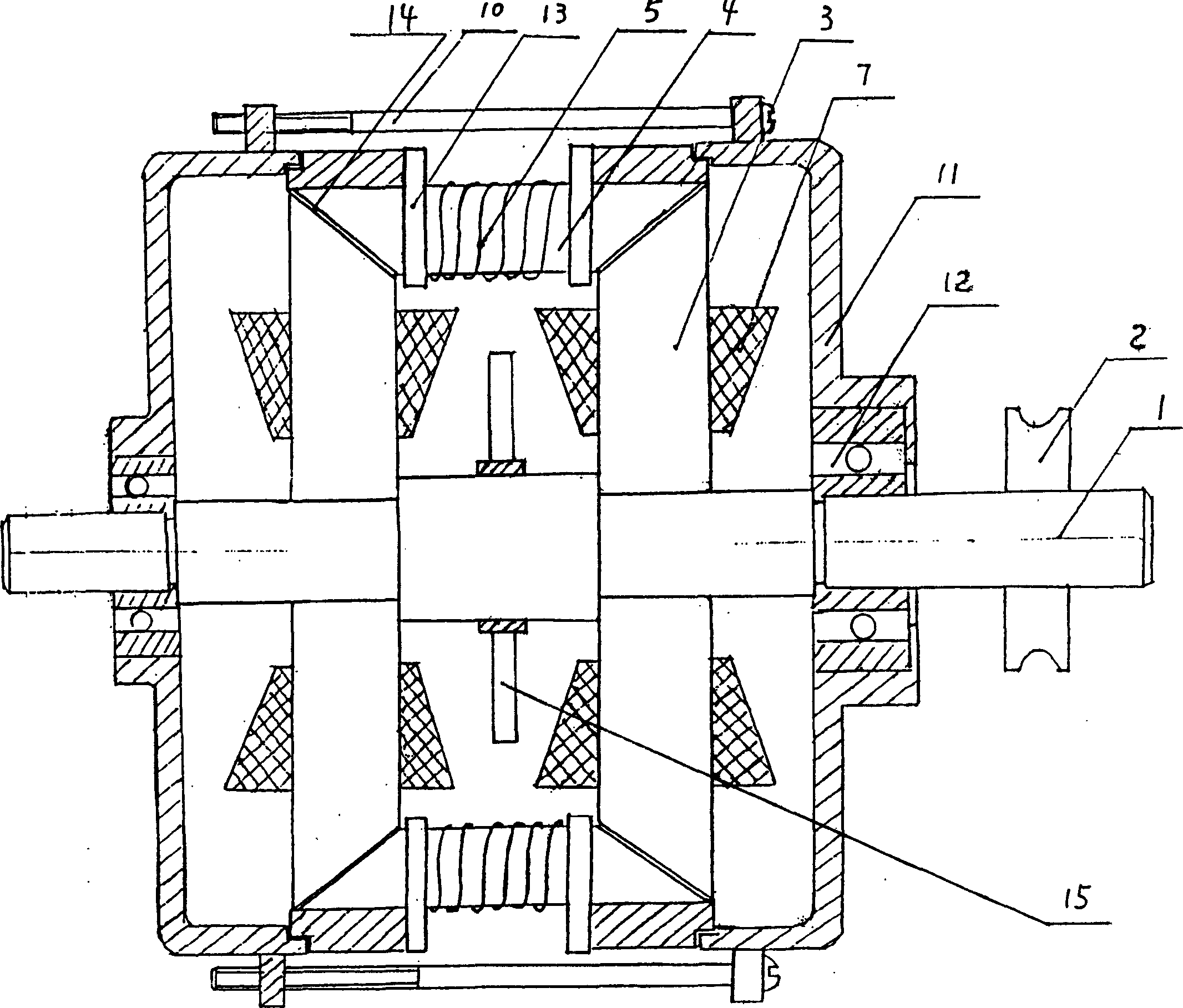

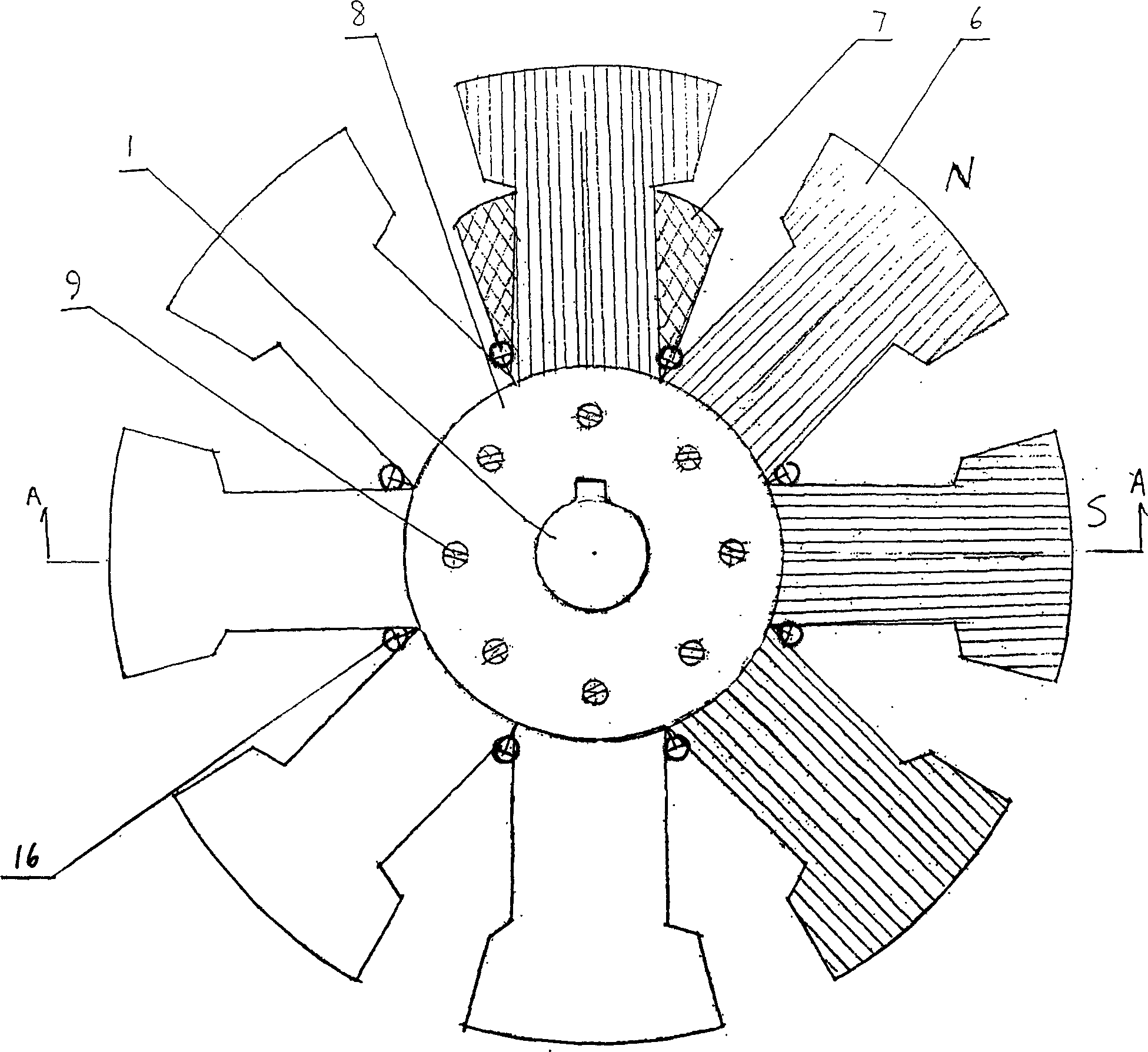

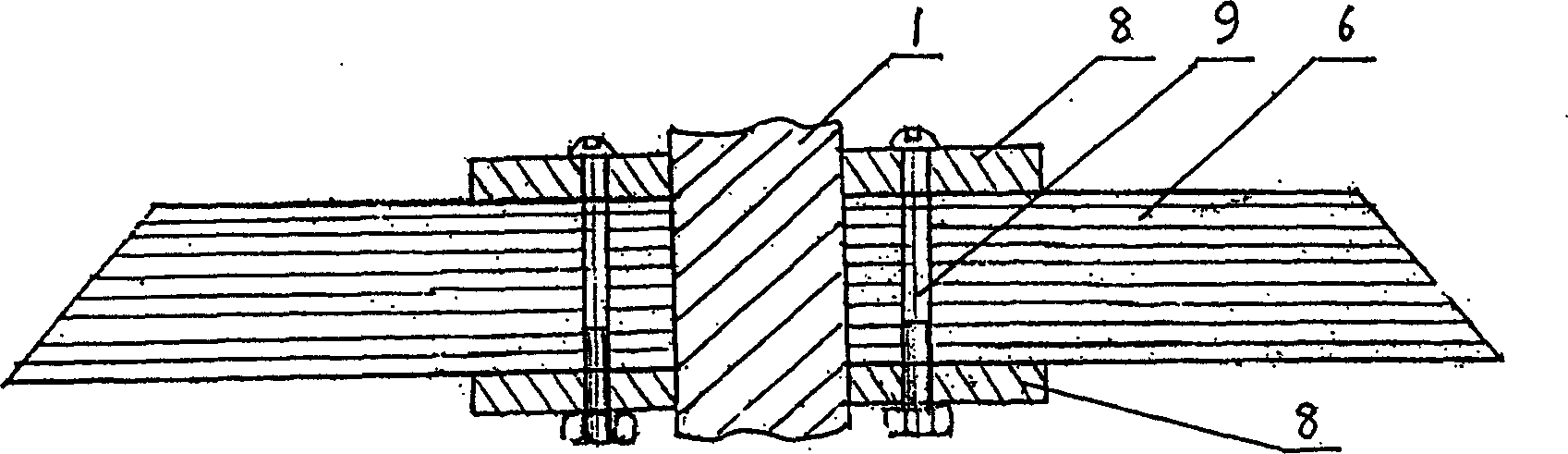

[0021] Referring to the accompanying drawings, the slotless asynchronous motor described in the embodiment includes a stator and a rotor. The rotor includes a rotating shaft 1 supported on two left and right end covers 11 through bearings 12. The left and right end covers 11 are fixed by end cover fixing bolts 10. The rotating shaft 1 is covered with a pulley 2 and two pole plates 3 inherently used as power output. The rotating shaft 1 is cylindrical and stepped, the middle section between the two pole disks 3 is the thickest, and the two end sections are the thinnest. On the middle section of the rotating shaft 1 located between the two pole disks 3, there are inherent fan blades 15, each of the rotor A pole plate 3 includes 8 magnetic poles 6 arranged radially and evenly, the inner section of each magnetic pole 6 is closely adjacent, and the outer section is a thickened trapezoidal surface. There are ventilation holes 16, and each magnetic pole 6 is superimposed and fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com