Apparatus for measuring thickness profile and refractive index distribution of multiple layers of thin films by means of two-dimensional reflectometry and method of measuring the same

A technology of refractive index distribution and multi-layer film, which is applied in measurement devices, optical devices, phase influence characteristic measurement, etc., can solve the problems of unsuitable measurement of film thickness profile, complex function and structure of measurement devices, and unrealistic economic viewpoints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

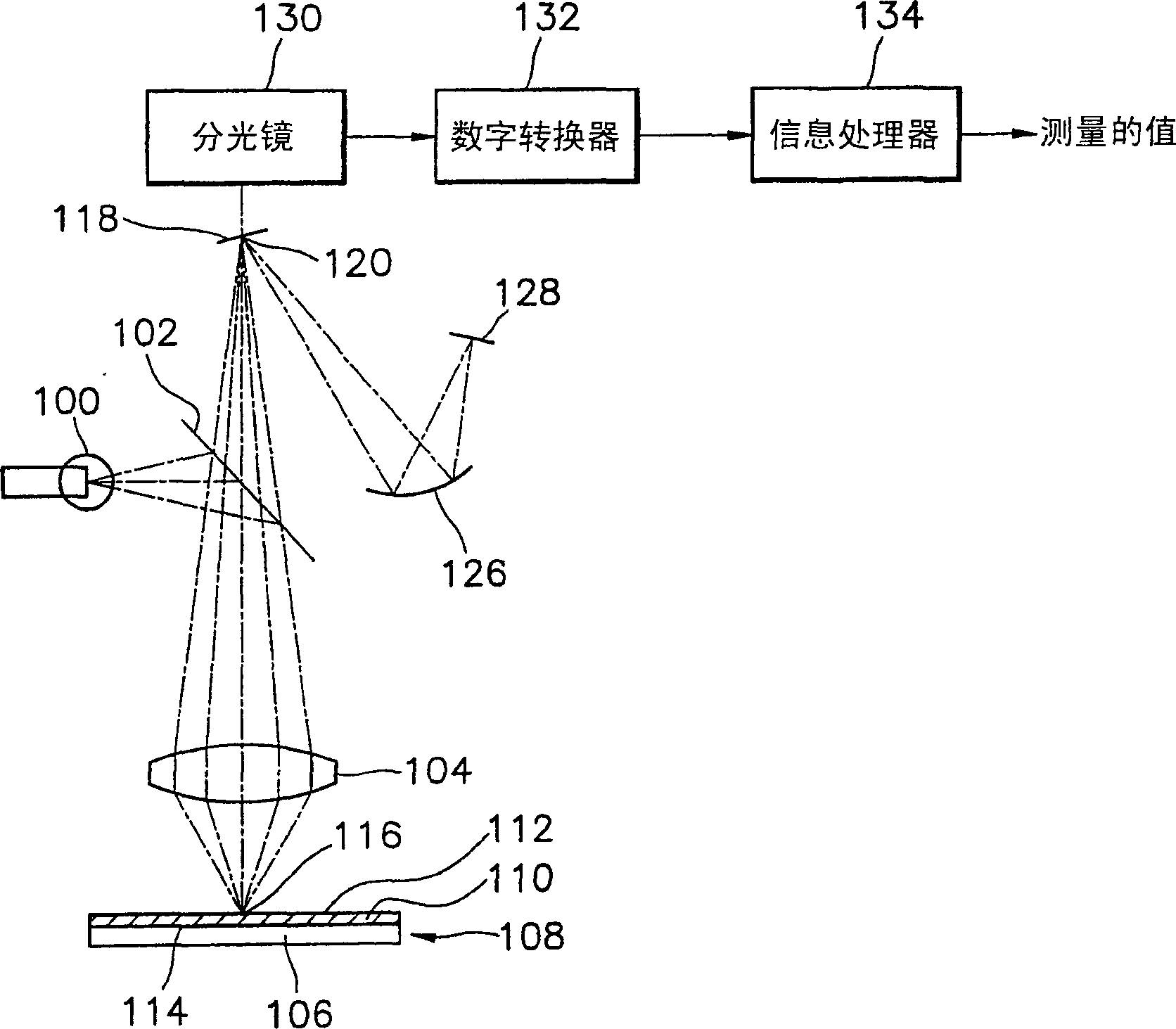

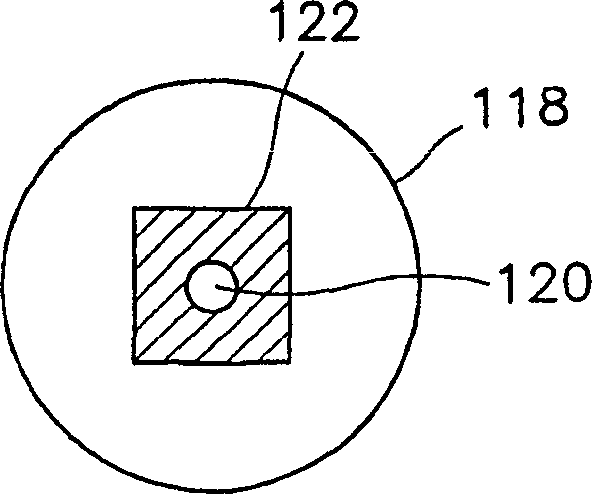

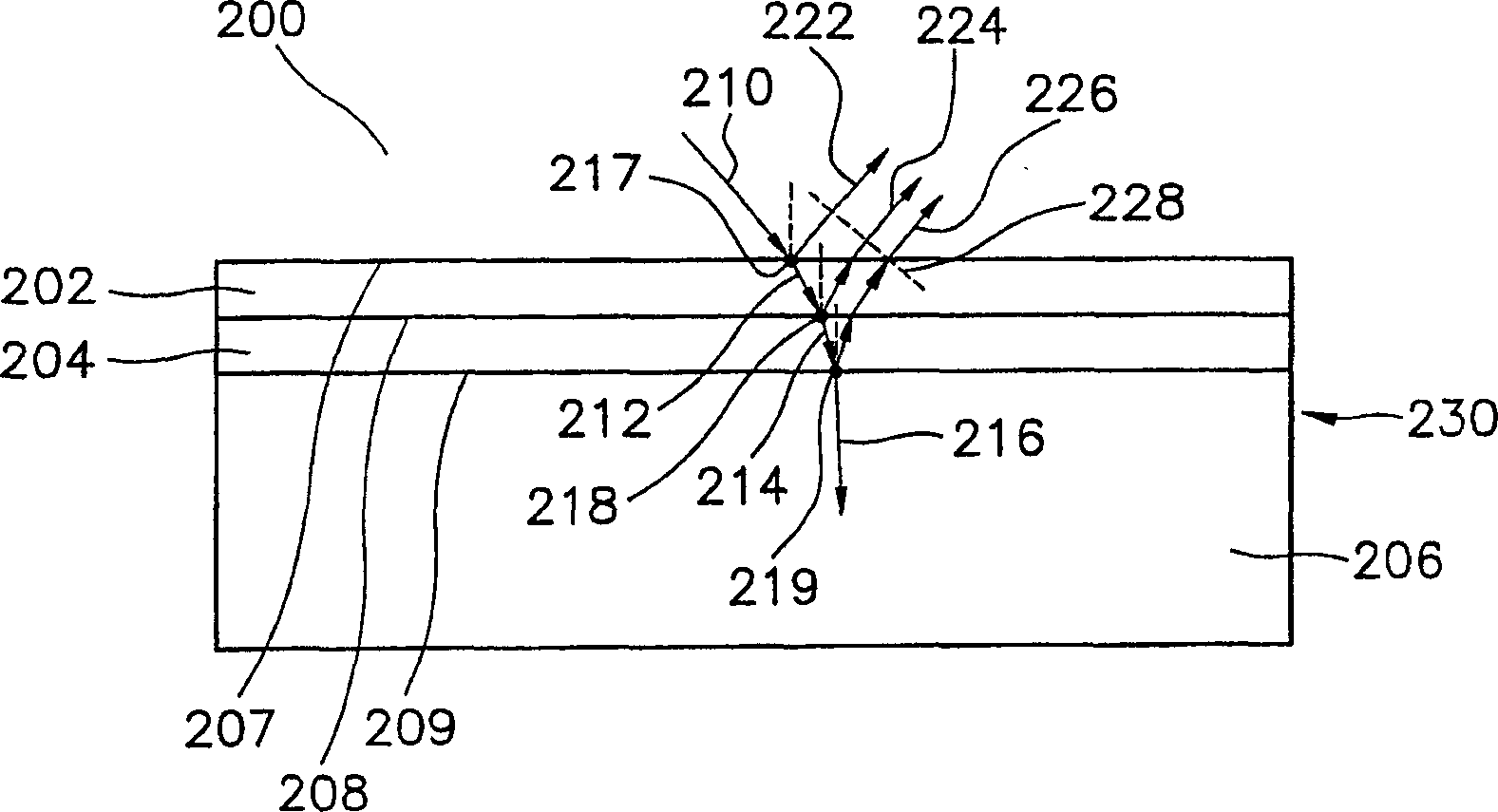

[0022] Figure 5 is a schematic diagram of a novel apparatus for measuring thin film thickness profiles and refractive indices according to the present invention. see Figure 5 , as an example according to the present invention, the device for measuring film thickness profile and refractive index distribution includes 5 modules, namely, optical unit, substrate carrier, picture image acquisition processor, image processor 548, information processor 550, system controller 552, and an information display unit.

[0023] Optical unit comprises light generation light source 500, condenser lens 502, iris (iris) 504, collimation lens 506 (first collimation lens), beam splitter 508, objective lens 510 (second collimation lens), auxiliary lens 530 (the first collimation lens) triple-value lens), and a filter wheel 534 equipped with a plurality of narrow bandpass filters 538. A visible light source is generally used as the light source 500 for measuring the film thickness. The light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com